Rotary marking electrolysis method of different-height bosses on surface of revolved body, and cathode system

An electrolysis method and technology of rotary body, applied in the direction of machining electrodes, electrode manufacturing, electric machining equipment, etc., can solve the problem of inability to realize the one-time machining of bosses of different heights, limiting the application range of spin electrolytic machining, and the contours of bosses on the surface of the casing. Complex problems, to achieve the effect of improving machining accuracy and machining stability, ensuring stability, and improving molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

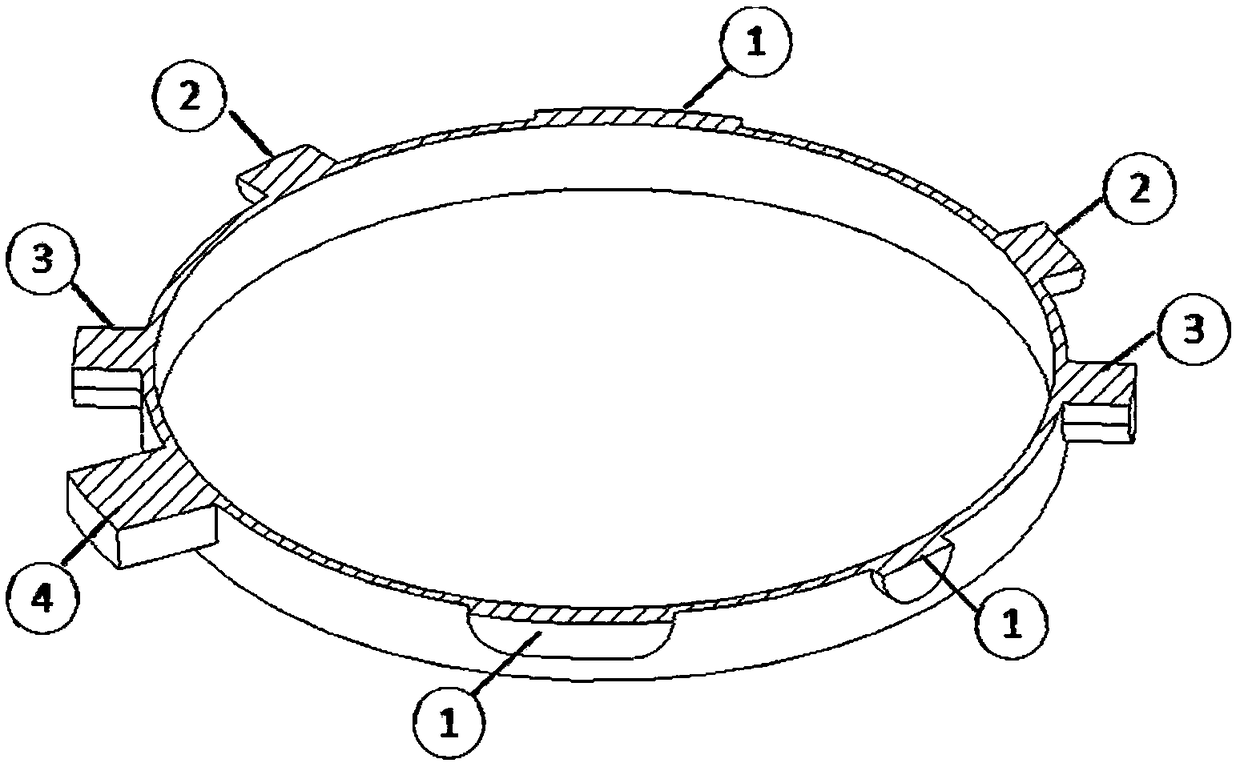

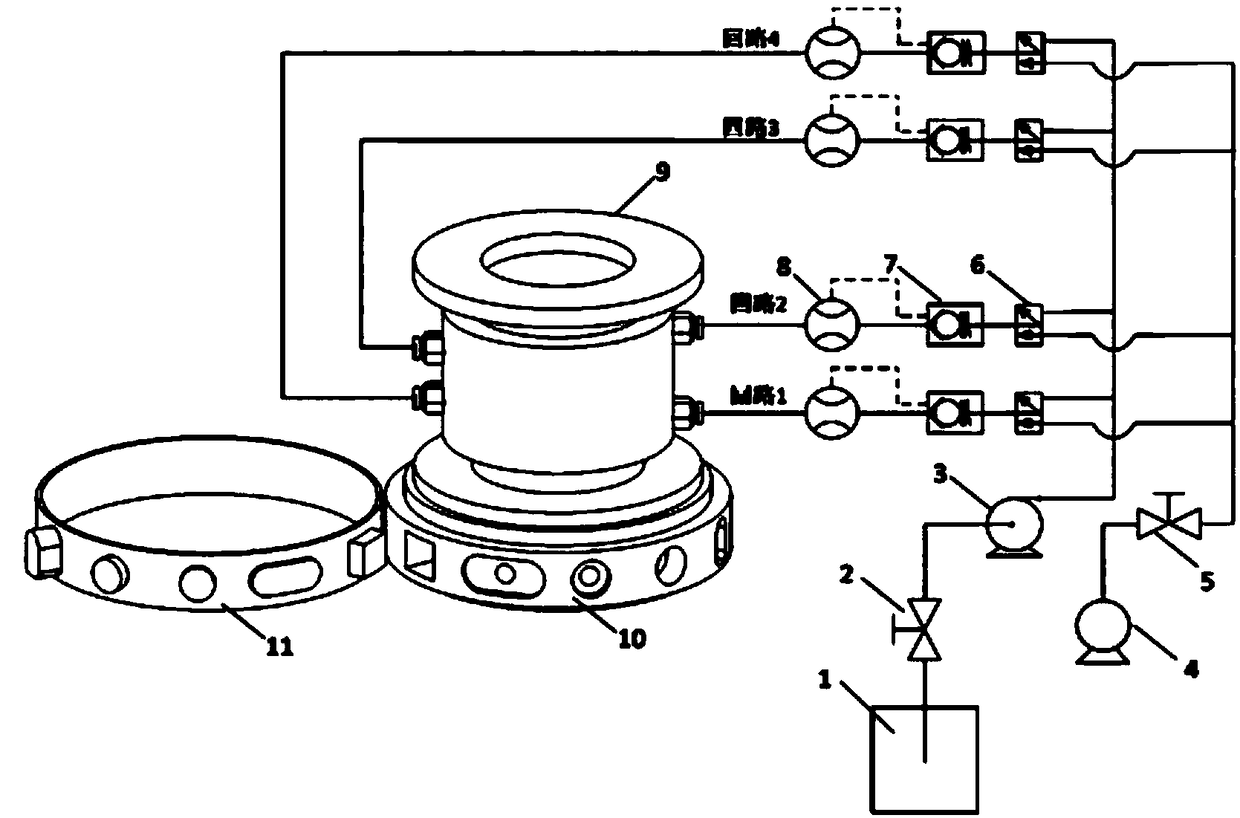

[0019] figure 1 Shown is a schematic diagram of the classification of bosses on the surface of the workpiece. The bosses are classified according to their heights. Those with the same height are classified into one category, and they are divided into ①, ②, ③, and ④ according to the height of the bosses from small to large, so as to determine the auxiliary supply. The number of liquid circuits and the gas / liquid switching time of each circuit, and the classification of the bosses also determine the type and number of the multi-way rotary joint 9 and the multi-way joint 17.

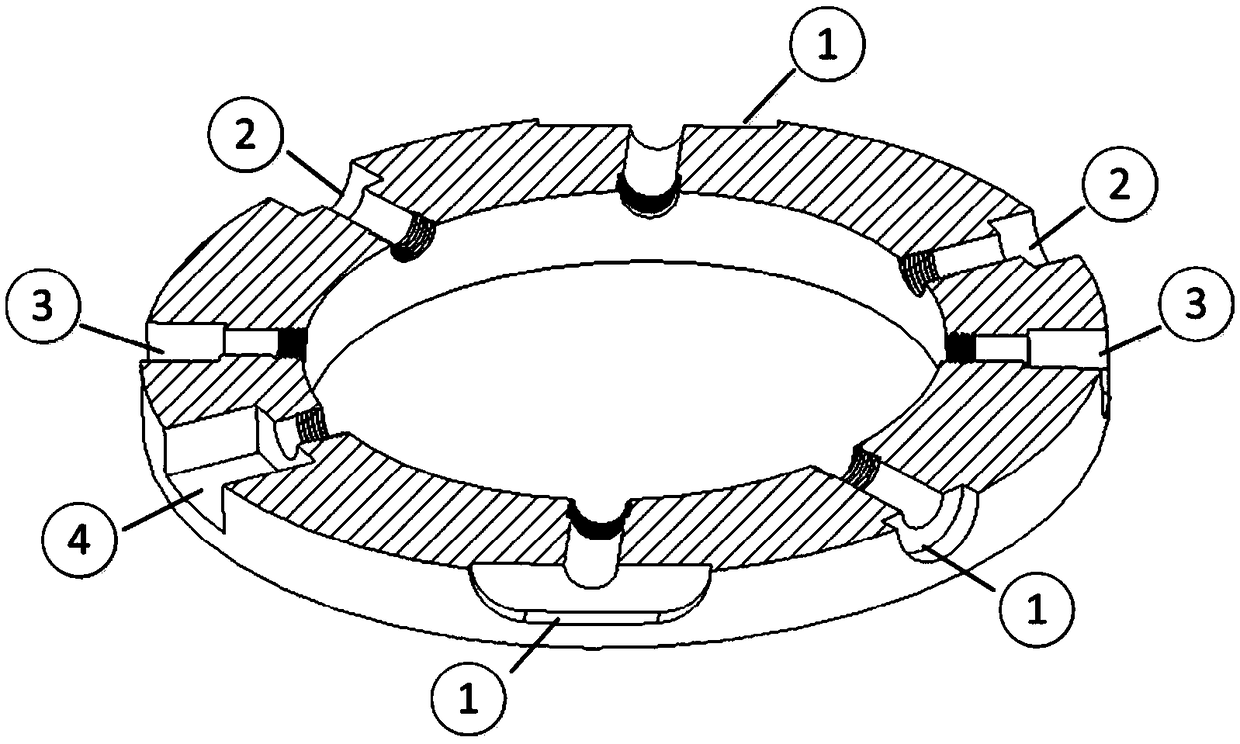

[0020] figure 2 The cathode structure of the tool shown, according to the figure 1 The shape of the groove on the surface of the cathode 10 is designed according to the contour of the boss on the surface of the workpiece. The groove is also divided into ①, ②, ③, and ④ according to its depth; the inner wall around the groove is insulated, and the bottom is not insulated. , the bottom of the groove is desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com