Electrolytic machining device

A processing device and electrolytic cell technology, which is applied in the direction of electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problems of inability to effectively discharge deep cavity electrolysis products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

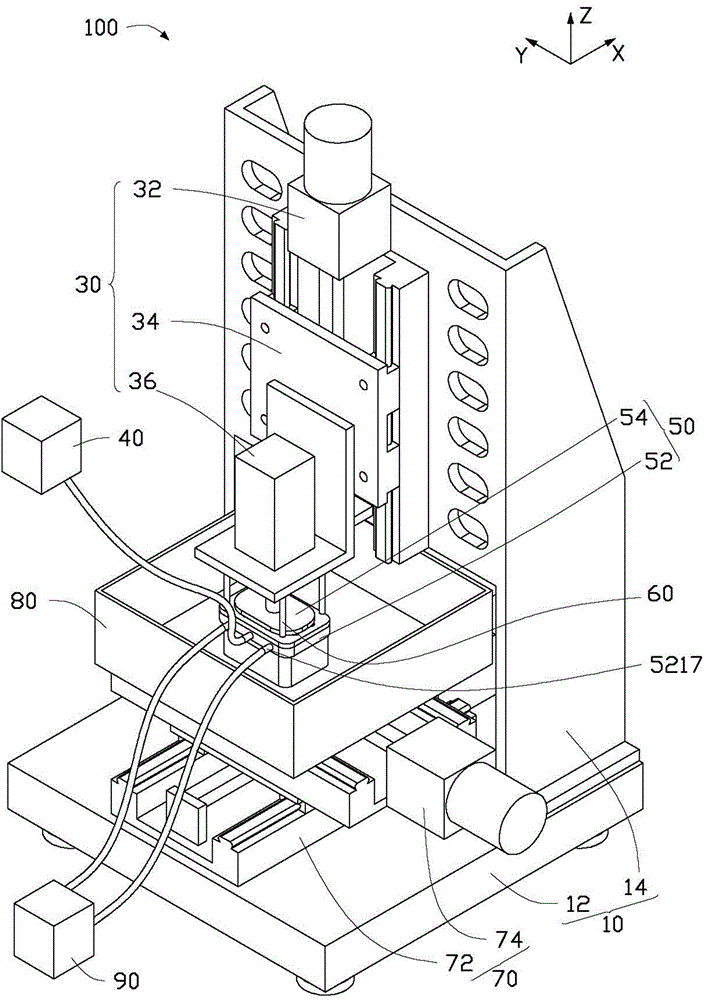

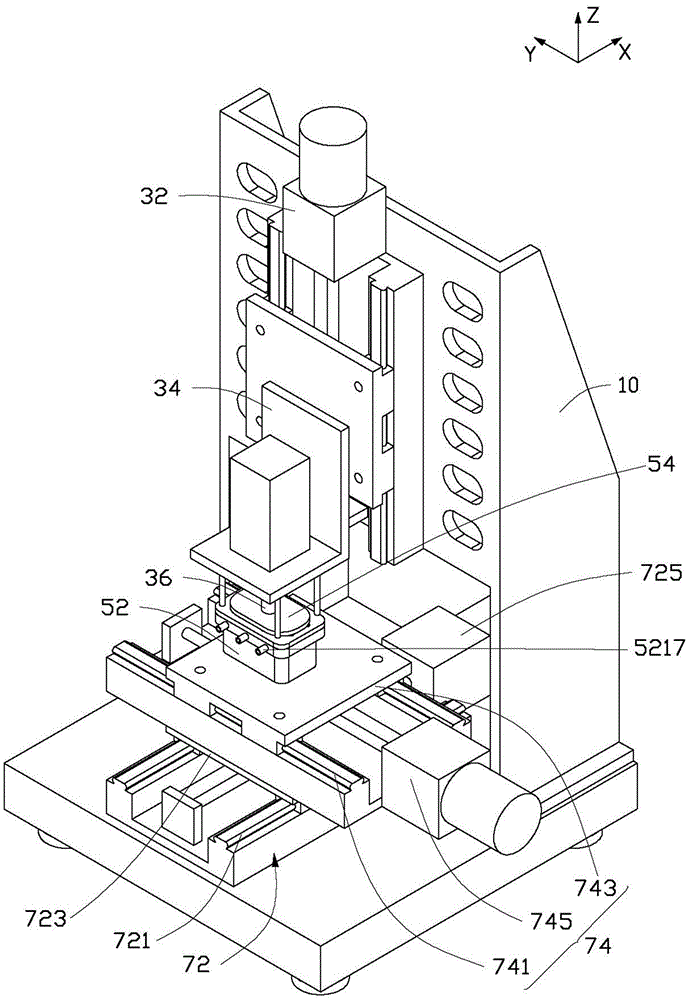

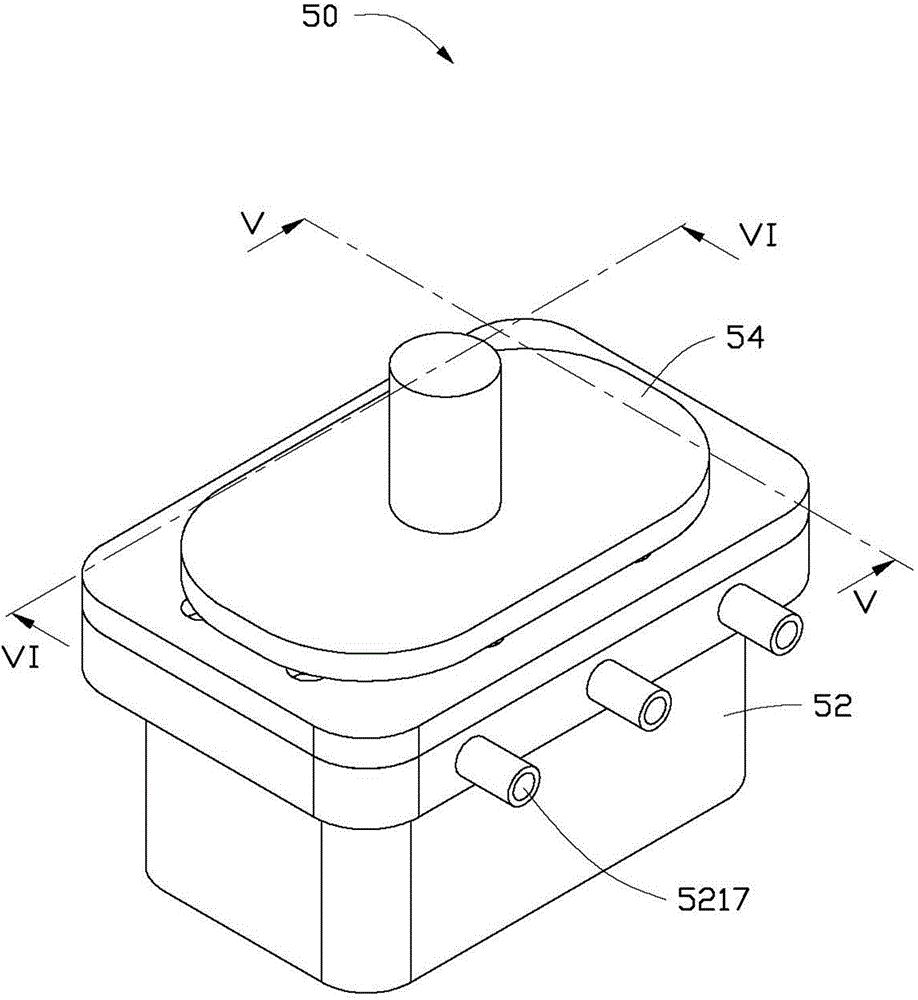

[0017] see figure 1 and Figure 7 , the electrolytic machining device 100 of the present invention is used to process and form a deep cavity 310 on a workpiece 300 and effectively discharge the electrolysis product 500 in the machining gap 600 . The electrolytic processing device 100 includes a fixed frame 10 , a feeding assembly 30 , a liquid supply pump 40 , an electrode assembly 50 , a moving assembly 70 , an electrolytic tank 80 and a vacuum pump 90 . Both the feeding assembly 30 and the moving assembly 70 are fixed on the fixing frame 10 and arranged opposite to each other. The electrode assembly 50 is fixed on the feed assembly 30 , and the feed assembly 30 can drive the electrode assembly 50 to reciprocate along the Z-axis direction. The electrolytic tank 80 is fixed on the moving component 70 , and the moving component 70 can drive the electrolytic tank 80 to move along the X-axis direction and the Y-axis direction perpendicular to the Z-axis direction. The vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com