Cutter joint assembly and processing system

A processing system and tool joint technology, which is applied in processing special circuits, metal processing equipment, electric processing equipment, etc., can solve the problems of time-consuming preparation work, low efficiency of tool replacement, and difficulty in setting up electric processing functions in the processing system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

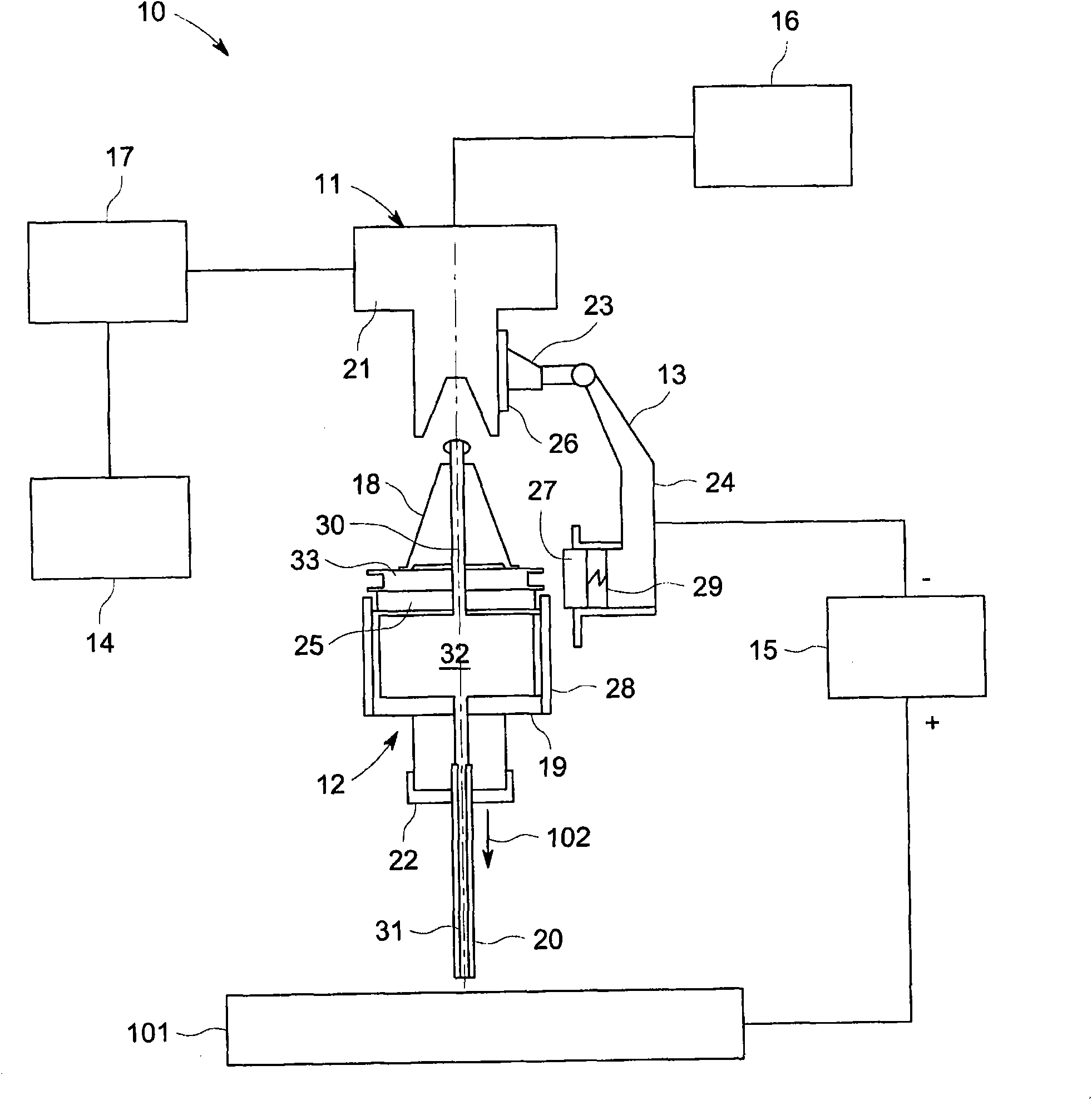

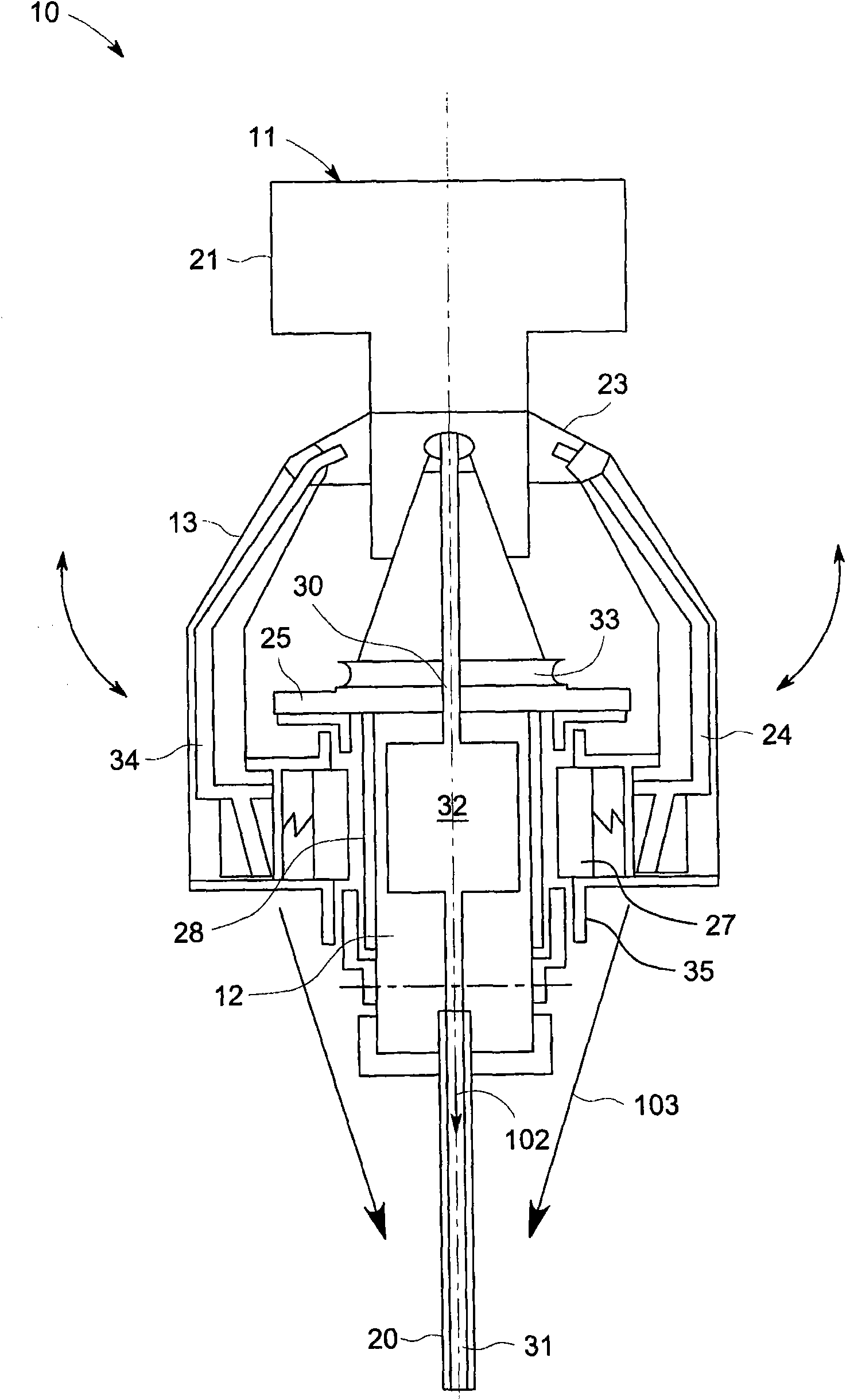

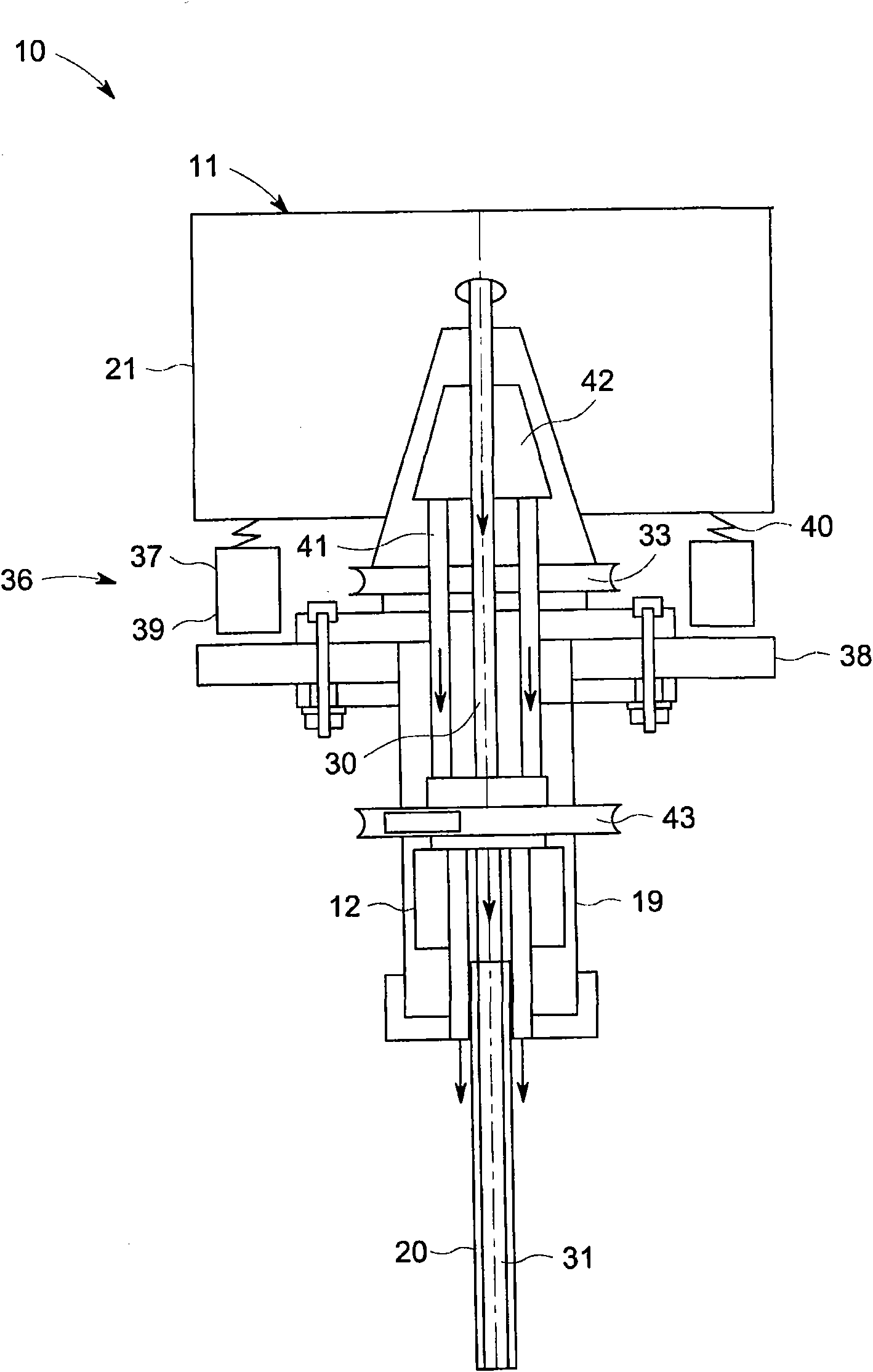

[0014] figure 1 A schematic diagram of one embodiment of a machining system 10 for machining a workpiece 101 is shown. In some embodiments, the processing system 10 includes computer numerical control (Computer Numerical Controlled, CNC) machine tools or machining centers (Machining Centers), which can automatically process the workpiece 101 with one or more tools according to a preset control program. The one or more tools may be stored in a tool magazine of the machining system. In some applications, the machining system 10 may not be provided with a tool magazine.

[0015] Such as figure 1 As shown, the machining system 10 includes a machine tool 11 , a tool joint assembly (not labeled), a tool transfer device 14 , a power source 15 , a machining fluid source 16 and a controller 17 . Wherein, the tool joint assembly includes an adapter 13 and a tool holding device 12 provided with a tool 20 . figure 1 The illustrated examples do not limit the invention. exist Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com