Non-spherical optical component composite machining and testing machine tools

A technology for optical parts and composite processing, applied in optical components, optics, metal processing, etc., can solve the problems of high measurement accuracy and low measurement cost, and achieve the effect of improving processing accuracy, improving processing efficiency, and compensating errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

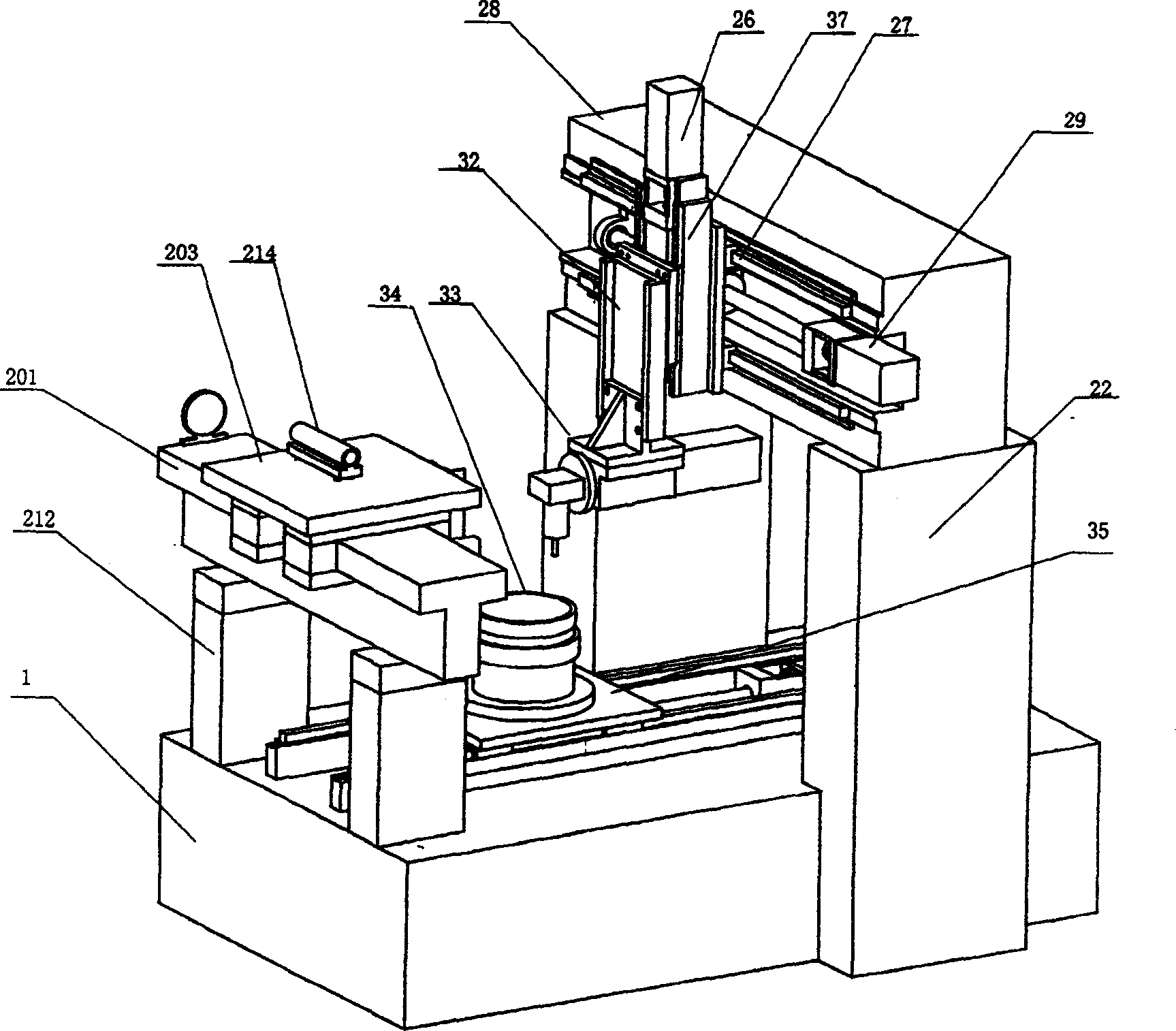

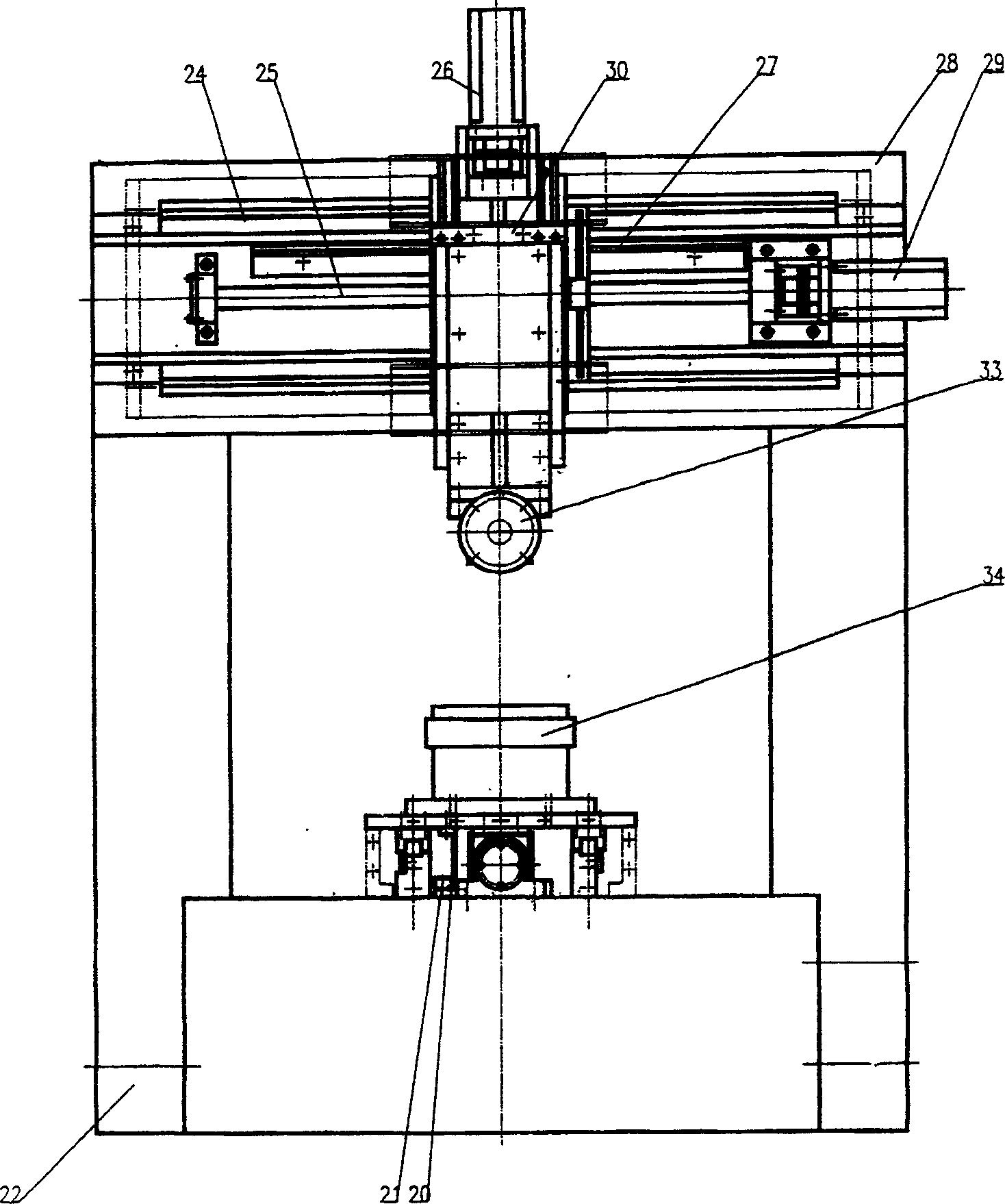

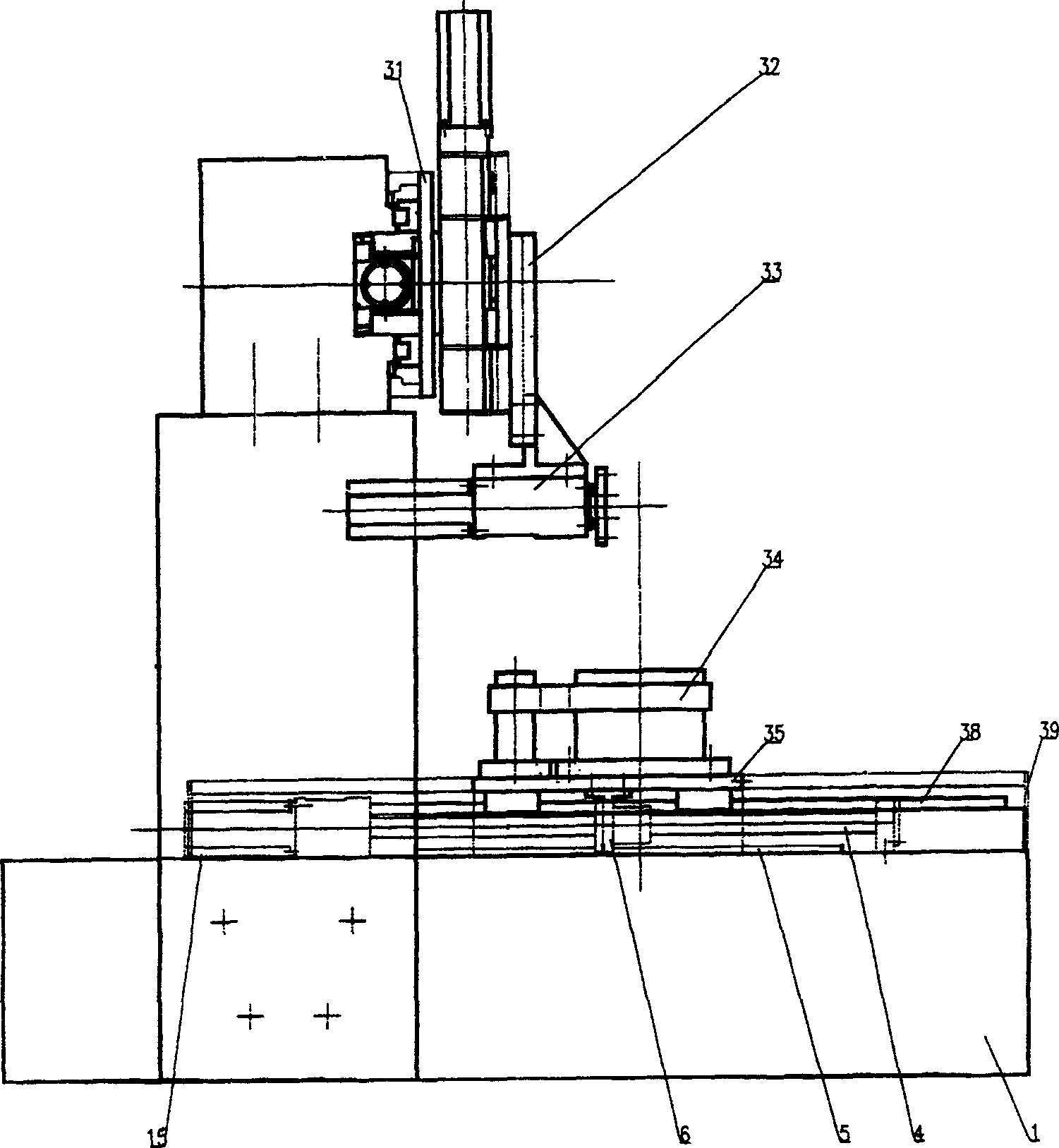

[0019] At present, the CNC machining of aspheric optical parts is a very complicated process. There are several key issues in this process: one is the quality of milling and grinding, the other is the accuracy of measurement, and the third is the speed of error convergence. These several problems comprehensively affect the processing accuracy and processing efficiency. High processing efficiency and precision are the basic requirements for manufacturing equipment. There are two different processing stages in actual processing: milling and grinding process and grinding and polishing process. Usually, this kind of machine tool realizes the conversion of milling and grinding and polishing process by changing the processing position. The structure of the machine tool is complex and the cost is high. On the basis of summarizing the work of predecessors, the present invention improves the existing aspheric optical parts processing machine tool with the goal of improving the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com