Intelligent control system for digital control machine tool and control method thereof

An intelligent control system and technology of CNC lathes, applied in the field of CNC lathes, can solve problems such as shortening the process design cycle, online measurement, and prolonging the process design cycle, so as to improve the level of intelligence and automation, simple processing and operation, and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

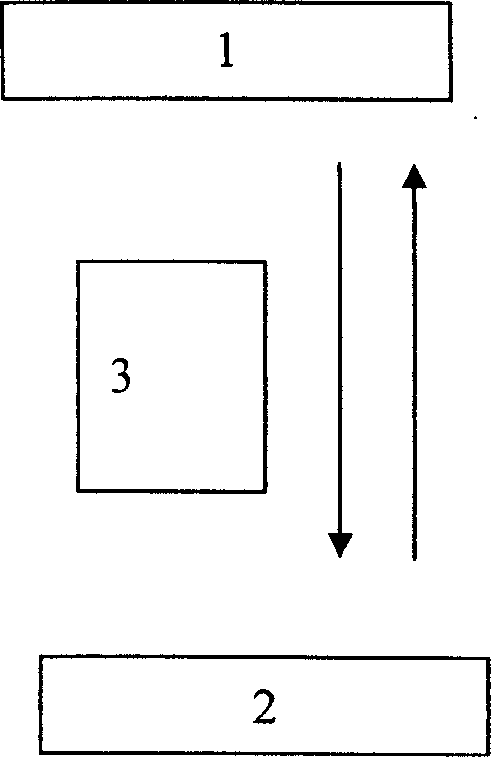

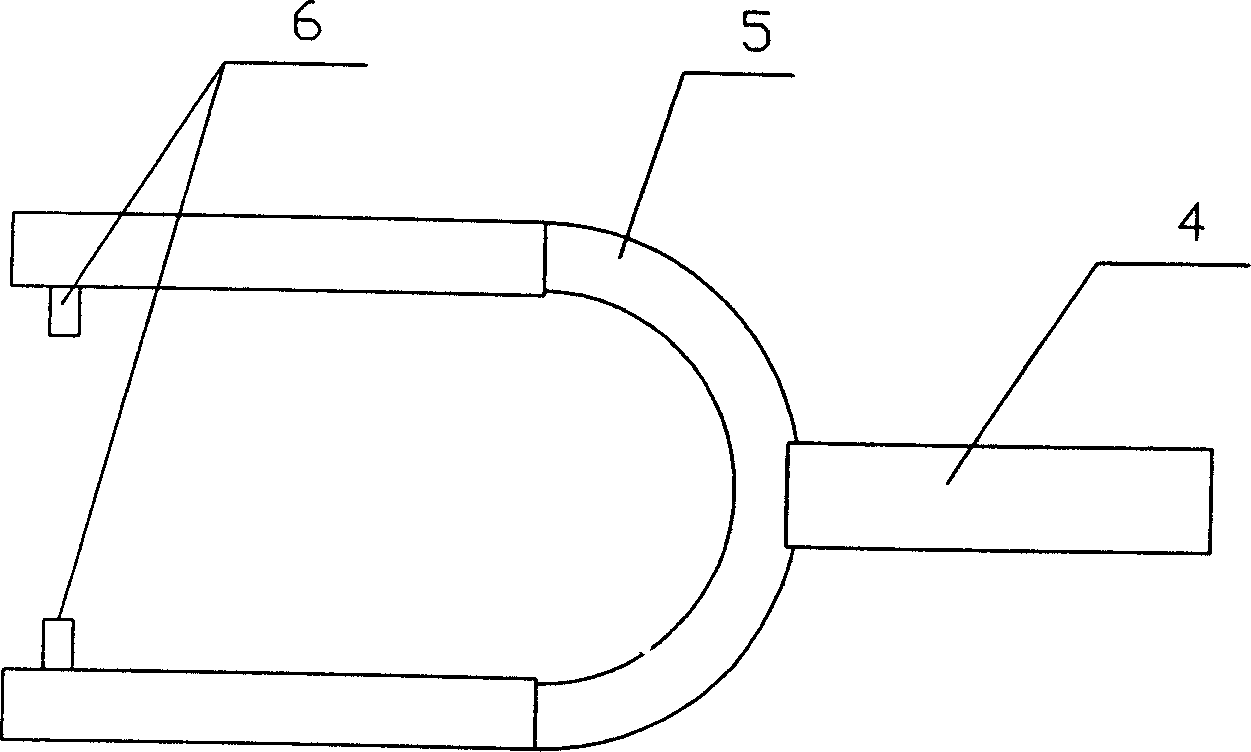

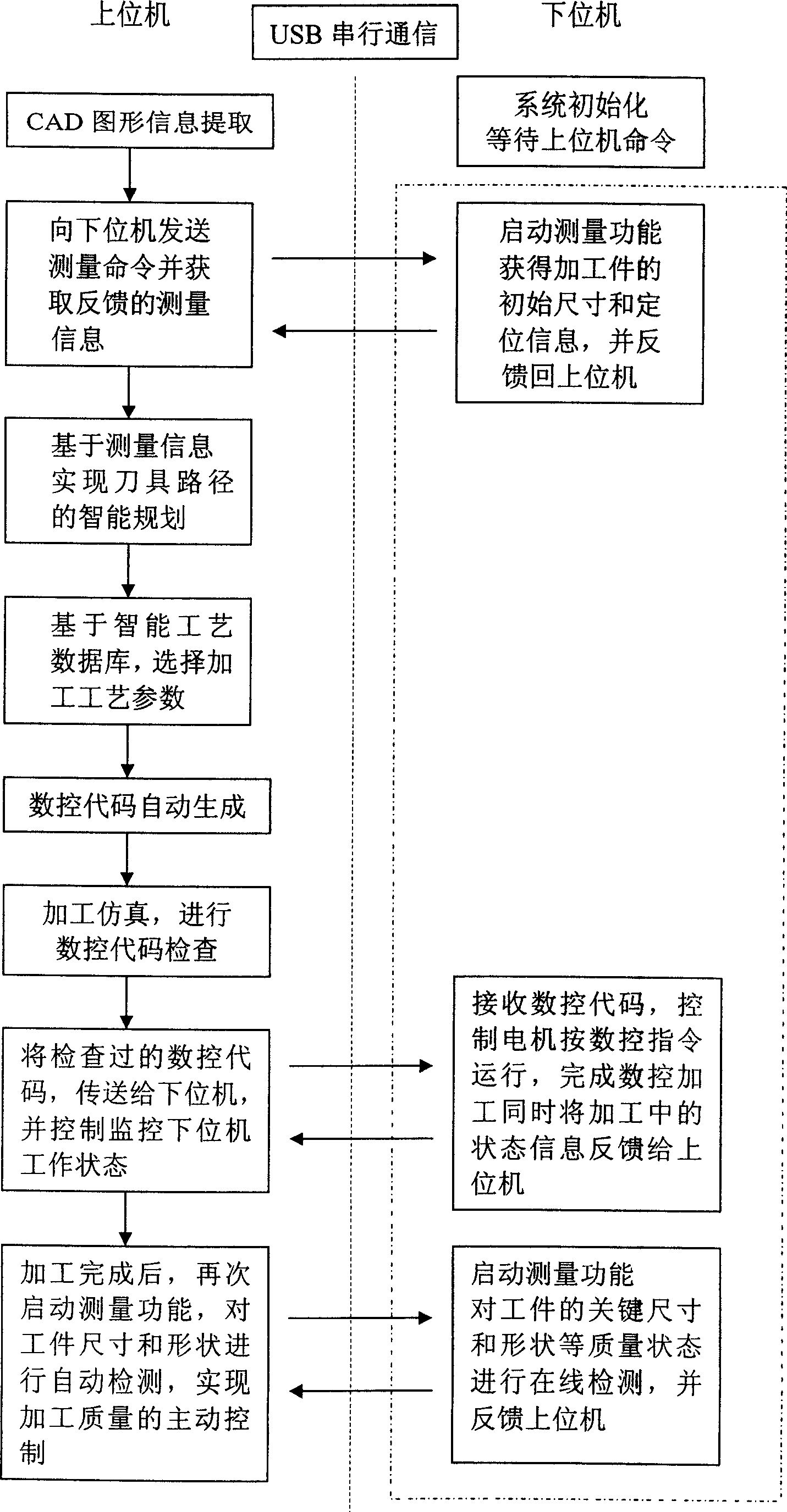

[0038] figure 1 The composition of the control system of the present invention is given. It has an upper computer 1, the upper computer 1 is a computer; the lower computer 2 is the control device on the CNC lathe, which is a DSP chip of the model TMS320LF2407A; the upper computer 1 and the lower computer 2 are connected through USB serial communication 3. It uses A high-speed USB with parallel bus and local DMA transfer capability, its model is PDIUSBD12. The upper computer 1 can extract CAD graphics information, intelligently plan tool paths, optimize process parameter databases, generate NC codes, and process simulations through corresponding software. The lower computer 2 realizes on-line measurement through the photoelectric detection device 3, controls the operation of the motor, and compensates the processing amount of the tool by the linear arc i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com