Automatic powder feeding laser induction composite coating method and device

A laser induction, cladding technology, applied in laser welding equipment, heating inorganic powder coating, manufacturing tools, etc., can solve the problems of high coating manufacturing cost, high maintenance cost, loss of cladding layer, etc., to improve the cladding The effect of speed and efficiency, convenient installation and positioning, and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

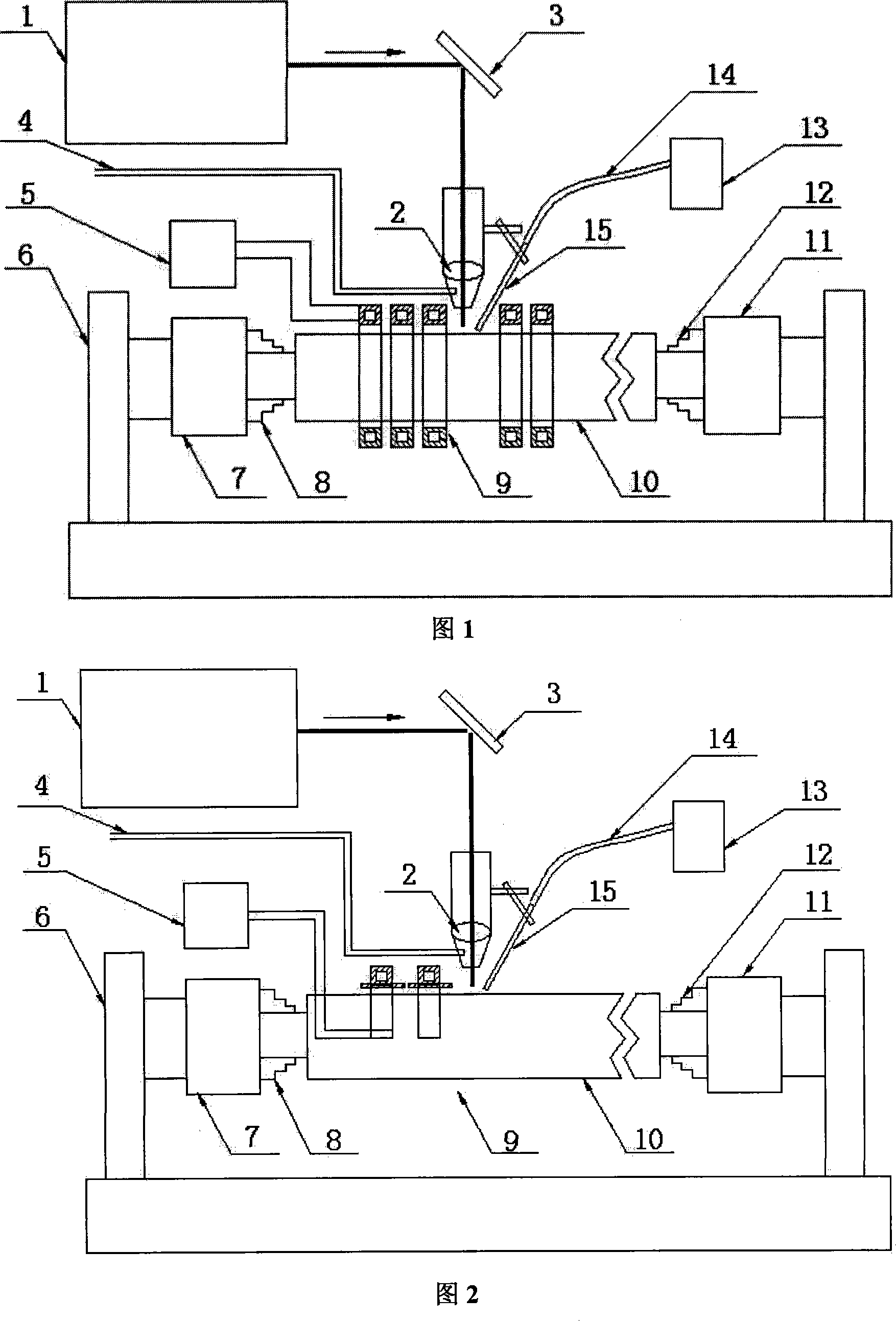

[0052] Example 1: Laser induction composite cladding treatment on the surface of small shaft solid parts

[0053] For small solid shaft parts, the specific implementation method is described by taking a roll with a roll diameter of 325mm as an example. The laser induction composite cladding method for other small shaft solid parts is similar.

[0054] Using the device shown in Figure 1, the speed is selected according to the diameter of the roll. For a roll with a diameter of 325mm, the speed is set at 0.5-10 rpm, which can be used for rapid cladding strengthening and repairing of solid parts such as rolls.

[0055] The basic steps to implement are as follows:

[0056] (1) Material selection. The cladding material adopts tungsten carbide + nickel-based metal composite material, in which the particle size of tungsten carbide is -140+240 mesh cast tungsten carbide, and the binder phase uses nickel-based self-fluxing alloy Ni60 with a particle size of -140+320 mesh. The tungste...

example 2

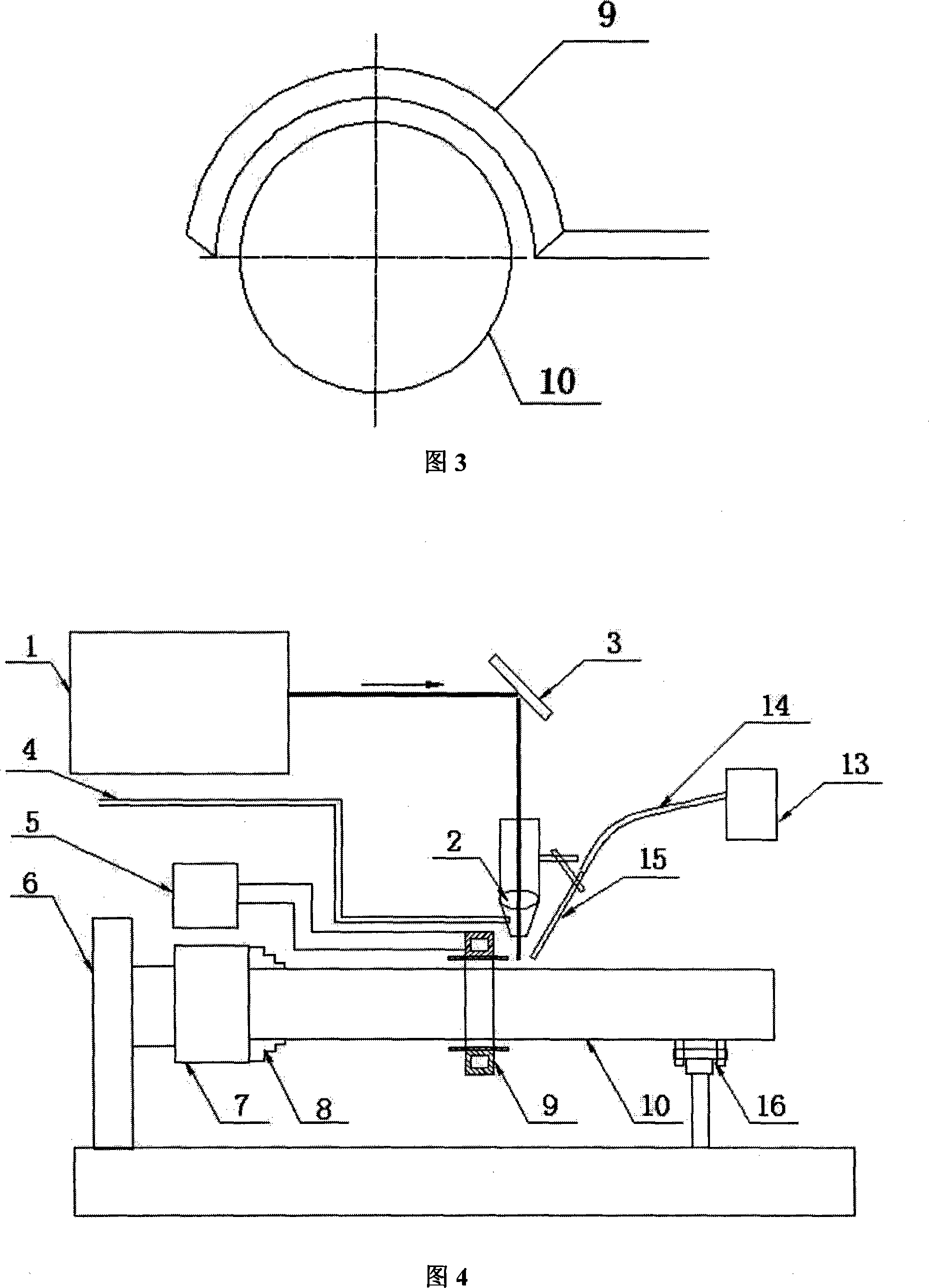

[0062] Example 2: Laser induction composite cladding treatment on the surface of large shaft solid parts

[0063] For large shaft solid parts, the specific implementation method is described by taking a roll with a diameter of 650 mm as an example. The laser induction composite cladding treatment method for the surface of other large shaft solid parts is similar.

[0064] Using the device shown in Figure 2, the rotation speed is selected according to the size of the roll diameter, mainly to ensure that the linear speed during laser processing is within the required range. For rolls with a roll diameter of 650mm, the speed is set at 0.3-5 rpm, which can be used for rapid cladding strengthening and repairing of solid parts such as large rolls.

[0065] The basic steps to implement are as follows:

[0066](1) Material selection. The cladding material adopts tungsten carbide + nickel-based metal composite material, in which the particle size of tungsten carbide is -140+240 mesh ...

example 3

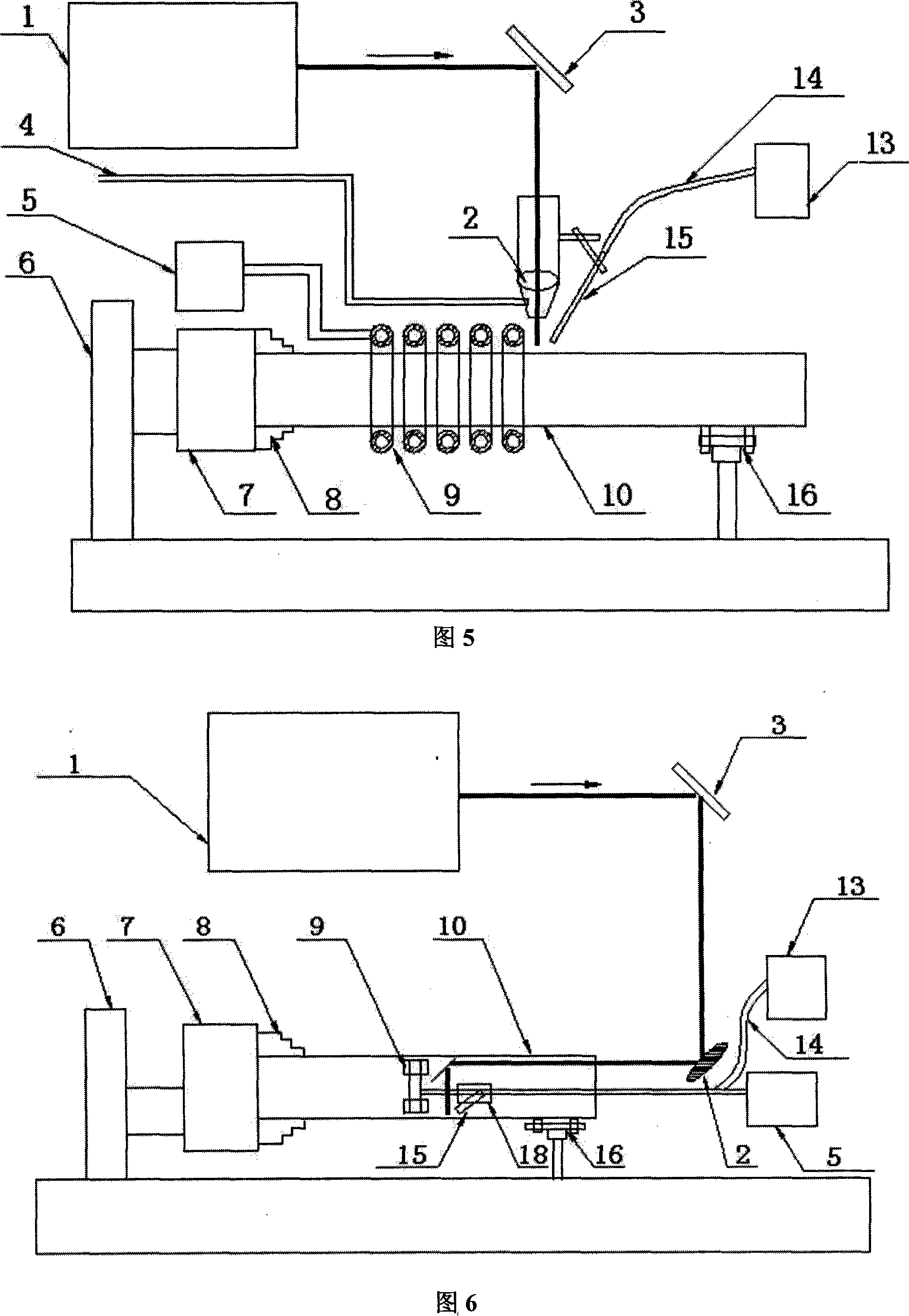

[0072] Example 3: Laser Induction Composite Cladding Treatment on the Outer Wall of Tubular Parts

[0073] For tubular components, a pipe with an outer diameter of 108 mm and a wall thickness of 5 mm is used as an example for illustration. The laser induction heating composite cladding treatment method for the outer surface of other tubular components is similar.

[0074] Adopt the device as shown in Figure 4, its implementation basic steps are as follows:

[0075] (1) Material selection. The cladding material adopts tungsten carbide + nickel-based metal composite material, in which the tungsten carbide particle size is -140+240 mesh cast tungsten carbide, and the binder phase uses nickel-based self-fluxing alloy Ni45 with a particle size of -140+320 mesh. The tungsten carbide is evenly mixed with the nickel-based self-fluxing alloy, and the mass percentage of the tungsten carbide is 60%. The substrate is made of low carbon steel pipe.

[0076] (2) The distance between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com