Moisture balance based cut tobacco moisture content control method for drum-type cut tobacco drier

A control method and shred drying machine technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as inability to meet higher requirements for process quality, fluctuations in process quality characteristics of shredded tobacco, and impact on cigarette quality, so as to avoid quality differences, Guarantee the quality of cigarettes and adjust the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

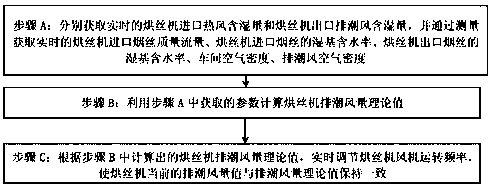

[0032] Such as figure 1 Shown, the present invention comprises the following steps:

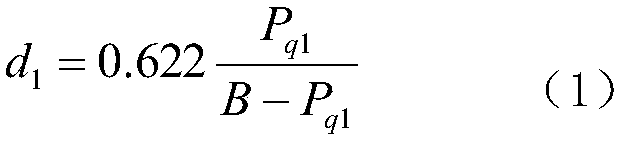

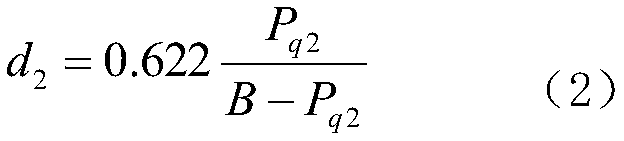

[0033] Step A: Obtain the real-time moisture content d of the hot air at the inlet of the silk drying machine respectively 1 D 2 ,

[0034] And obtain real-time cut tobacco mass flow M at the inlet of the shred dryer through measurement 1 , Moisture content on a wet basis of imported shredded tobacco of the shred dryer ω 1 , Moisture content on a wet basis of shredded tobacco at the outlet of the shred dryer ω 2 and workshop air density ρ 1 and air density ρ of tidal wind 2 .

[0035] Step B: Based on the principle of moisture balance, according to the target moisture content of the exported shredded tobacco, use the real-time data obtained in step A

[0036] Moisture content of hot air imported from silk drying machine d 1 , Moisture content of the exhaust air at the outlet of the silk drying machine d 2 , The mass flow rate M of cut tobacco imported from the shred drying machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com