Transparent vitreous surface wiping material preparation method

A technology for wiping materials and transparent glass, applied in cleaning equipment, applications, non-woven fabrics, etc., can solve the problem of not being able to meet no water stains and scratches at the same time, and achieve good bioabsorbability, strong dust ability, and good biological phase. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

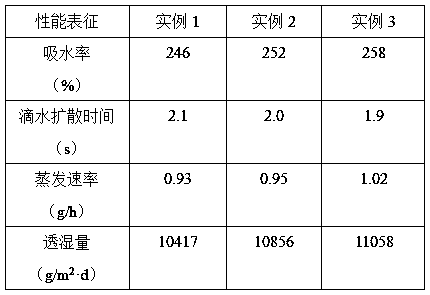

Examples

Embodiment Construction

[0024] According to the mass ratio of 1:10, the polyvinyl alcohol fiber and silica sol are mixed respectively, and the mass ratio of the ball to the material is 1:3, the ball is zirconia, the diameter is 6-8mm, and the speed is 160-200r / min. After 2 hours, the mixed material is obtained. Add absolute ethanol and 8% acetic acid solution in the mixed material according to the mass ratio of 1:5:0.3, seal and continue ball milling for 1 to 2 days to obtain the mixed slurry. The mixed slurry Put it in an oven at a temperature of 80-90°C and dry it to constant weight to obtain modified polyvinyl alcohol fibers, and perform the same modification treatment on viscose fibers and polylactic acid fibers respectively to obtain modified viscose fibers and modified polylactic acid fibers. Polylactic acid fiber; mix modified polyvinyl alcohol fiber, modified polylactic acid fiber and modified viscose fiber according to the mass ratio of 1:1:1.5 to obtain the base fabric, and the linear speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acupuncture depth | aaaaa | aaaaa |

| Needling density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com