Continuous preparation device and method for self-twisting nanofiber yarn

A nanofiber and preparation device technology, applied in the field of textile processing, can solve the problems of poor continuous production stability of nanofiber yarn, low mechanical strength of the yarn, complicated twisting process, etc., and achieves tight fiber cohesion, high production efficiency, High degree of orientation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

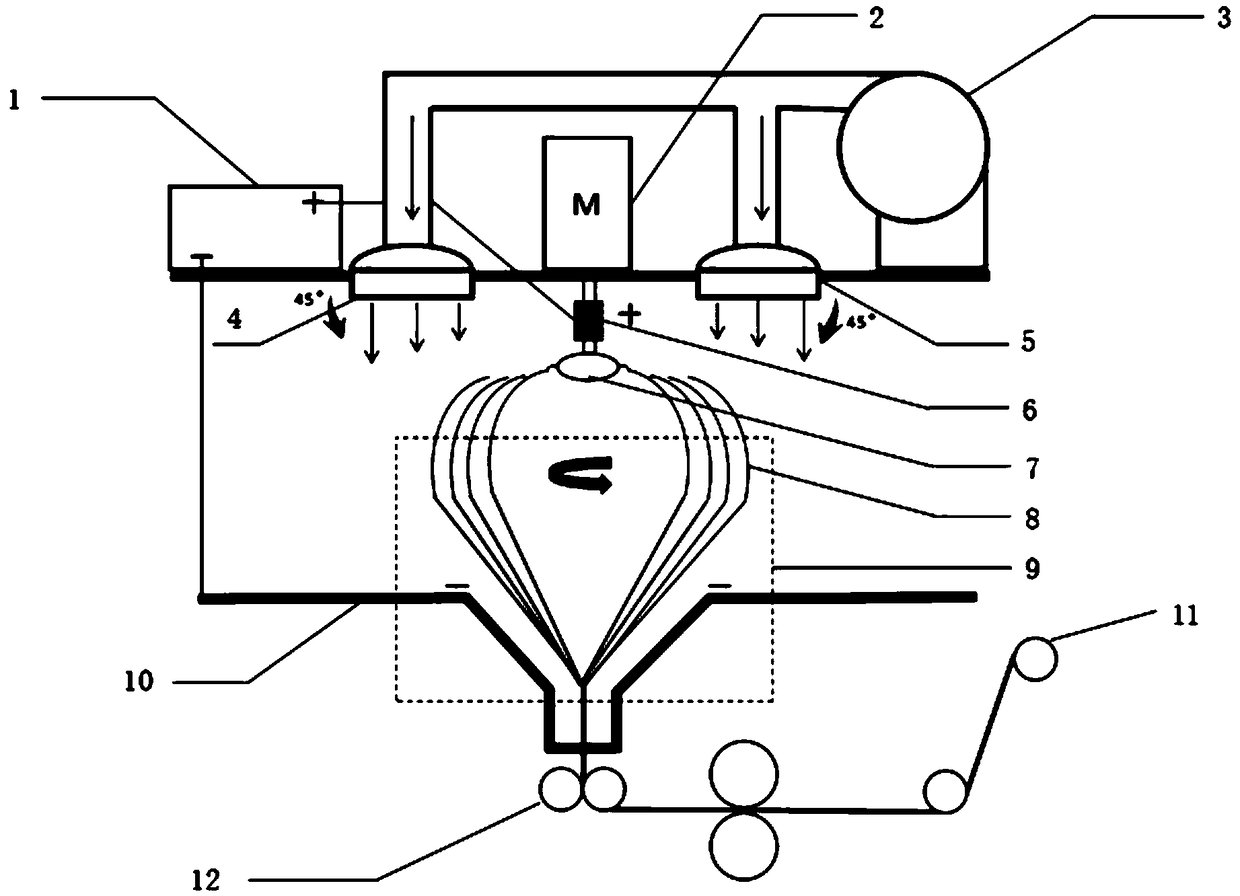

[0045] Next, the spinning solution prepared by ethyl cellulose and ethanol / water solution is used for spinning. The spinning solution with a concentration of 20% is injected into the spinneret 7 by a peristaltic pump, the spinneret 7 is connected to the positive pole of the electrostatic generator 1, and the distance between the spinneret 7 and the top of the funnel-shaped cluster 10 is 10 cm , the angle of the air shower 4 and 5 is 30°, the opening angle of the funnel-shaped cluster 10 is 60°, the electrostatic generator 1 is turned on, the voltage is adjusted to 6kV, the motor 2 is started, and the rotating speed is adjusted to 2000rpm, when the self-twisting zone 9 appears At this time, the winding roller 11 is started, the twisted nanofiber yarn is pulled out through the guide roller 12 under the airflow traction, the winding motor is started, and the set speed is 80rpm, and the nanofiber yarn is continuously collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com