Kapok/fine staple cotton ring spinning blended yarn and production method and use thereof

A production method, the technology of fine-staple cotton, applied in the field of yarn manufacturing, can solve the problems of unsatisfactory spinning performance index of kapok fiber and poor spinnability of kapok fiber, so as to reduce fly and static electricity, improve spinnability, and cohesion tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

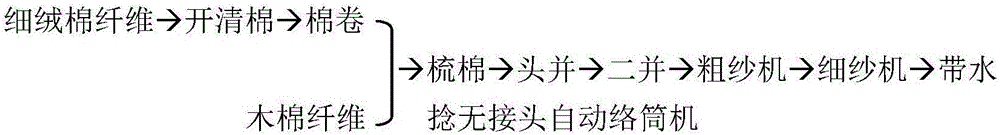

Method used

Image

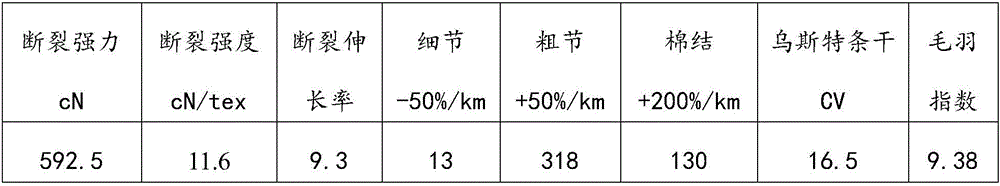

Examples

Embodiment 1

[0029] A kapok / fine-staple cotton ring-spun blended yarn is prepared by the following method:

[0030] (1) Kapok fiber pretreatment

[0031] The kapok fiber has high hollowness, low density, low humidity and less short fiber crimp. The present invention performs humidification and weight-enhancing treatment on the kapok fiber in advance to improve its spinning performance, and the temperature of the water for humidifying and weight-enhancing the kapok fiber is 40 -50 ℃, evenly spray the kapok fiber with warm water to fully infiltrate it;

[0032] (2) Cotton cleaning process: kapok fiber has good single fiber properties, few neps and impurities, and does not need to open and clean cotton during processing; process to form laps;

[0033] (3) Carding process: adopt the method of evenly mixing and feeding the cotton layer, lay the kapok fiber on the back of the carding machine, and then mix the fine cotton roll with the kapok fiber net according to the weight ratio of 65:35, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com