Logistics clamping holding machine

A clamping machine and logistics technology, applied in the field of logistics, can solve the problems of reducing the protection effect of the carton on the inner items, damage to the smooth surface of the carton, etc., and achieve the effect of preventing offset and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

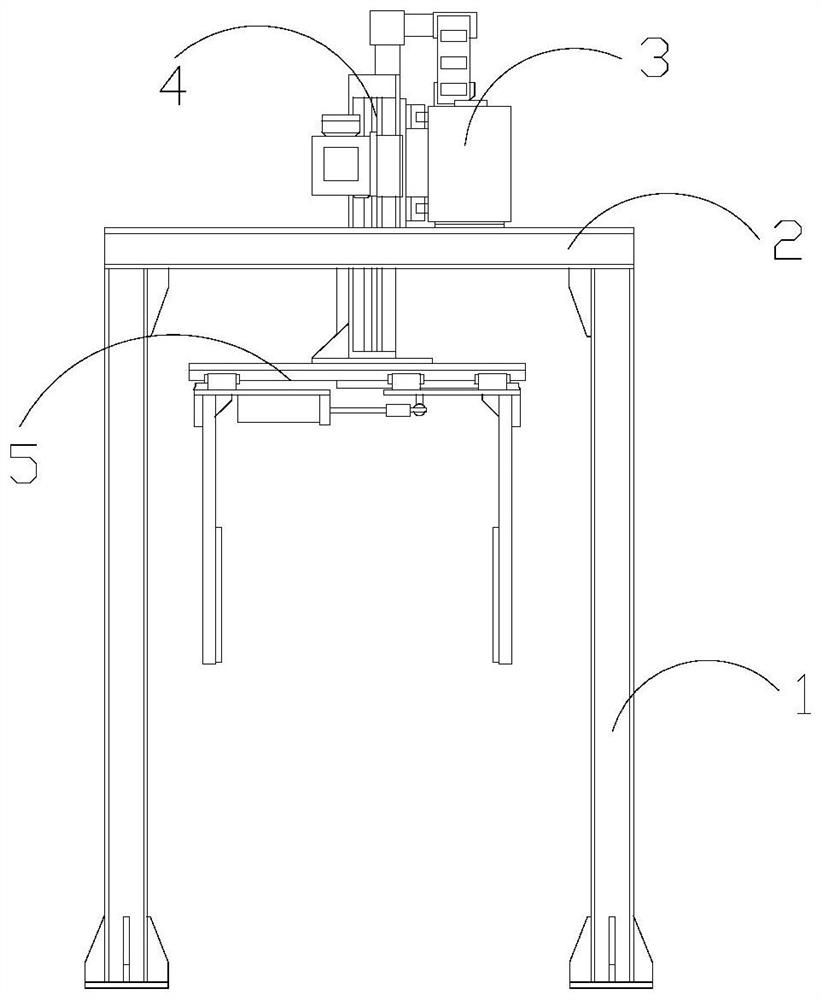

[0028] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

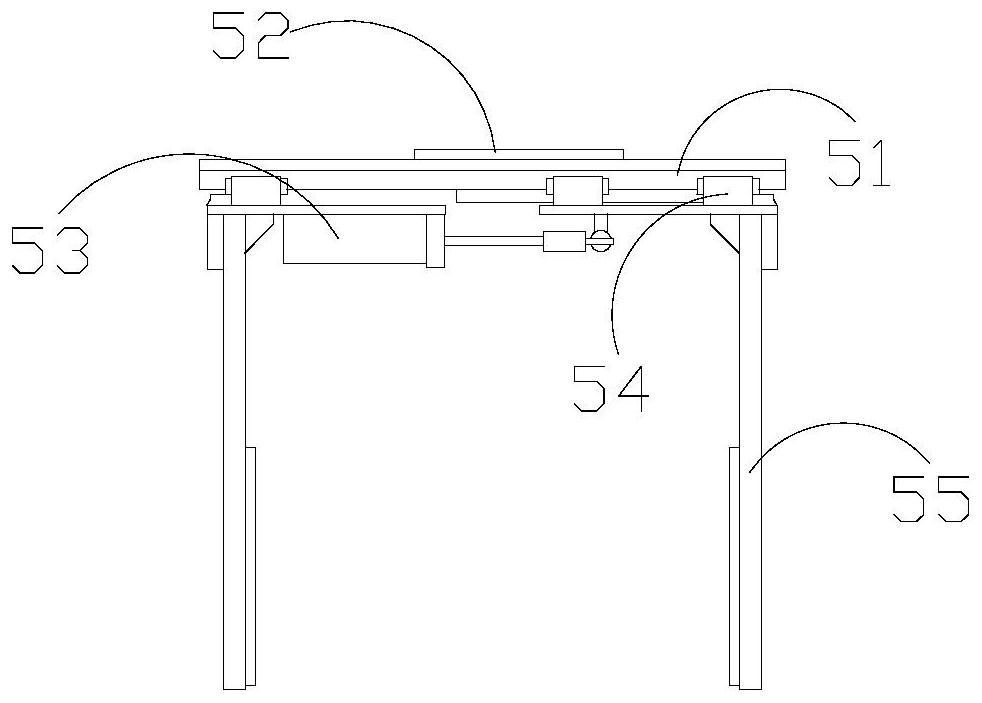

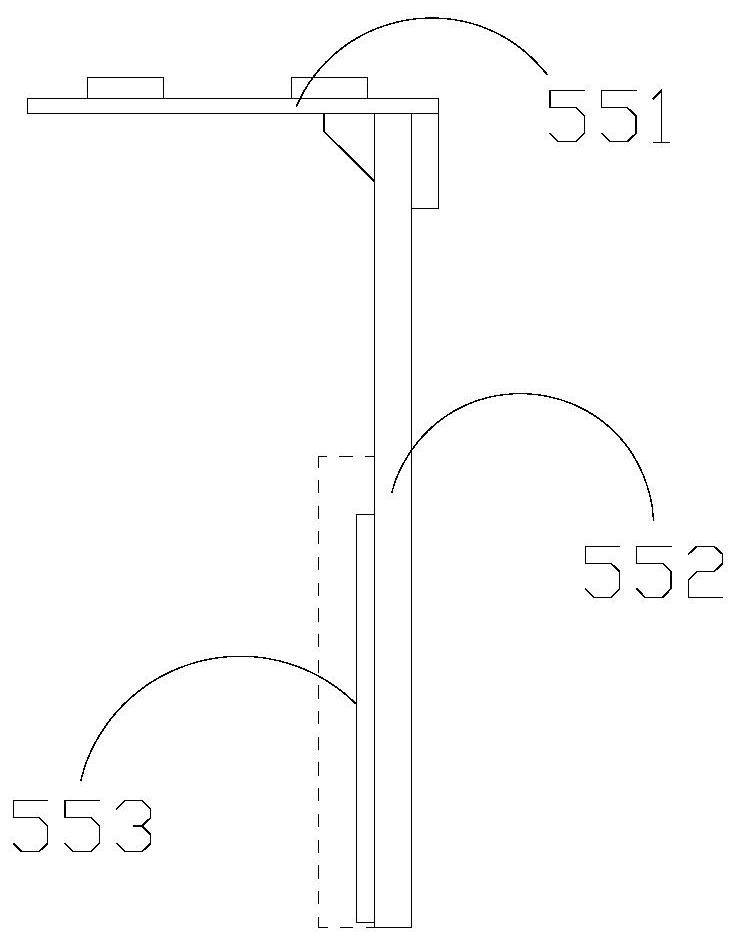

[0029] Its structure includes a frame 1, a transverse guide rail 2, a drive box 3, a longitudinal guide rail 4, and a clamping structure 5. The transverse guide rail 2 is horizontally installed on the upper end of the frame 1 and welded together, and the drive box 3 is installed on the transverse guide rail 2. between them and adopt flexible connection, the longitudinal guide rail 4 is vertically embedded and installed inside the drive box 3 and is located between the transverse guide rails 2, and the clamping structure 5 is vertically installed at the lower end of the longitudinal guide rail 4 and adopts mechanical connection; The clamping structure 5 includes a sliding rail 51, a support frame 52, a cylinder 53, a sliding block 54, and a clamping plate 55. The sliding rail 51 is horizontally installed on the lower end of the supporting frame 52 and welde...

Embodiment 2

[0036] Example 2: Please refer to Figure 5-Figure 8 , the specific embodiments of the present invention are as follows:

[0037] The side splint 53d includes a plate body d1, an exhaust structure d2, and a suction cup structure d3. The exhaust structure d2 is embedded and installed inside the plate body d1 and adopts a flexible connection. The suction cup structure d3 is installed on the left side of the exhaust structure d2 And the inner side is connected, the board body d1 is embedded and installed in the inner side of the embedded frame 53a and adopts a flexible connection.

[0038] refer to Figure 6 , the exhaust structure d2 includes an outer ring d21, a blocking plate d22, a movable shaft d23, and a movable structure d24, the blocking plate d22 is installed inside the outer ring d21 and distributed in a ring, and the movable shaft d23 is movably connected to the outer ring d21 The inner side is mechanically connected with the blocking plate d22 respectively. The mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com