Knitting method of multi-bar warp-knitting machine

A warp knitting machine and ground comb technology, applied in the field of weaving, can solve the problems of blurred mesh, decreased longitudinal elasticity and high cost of knitted fabrics, meet the requirements of anti-shedding and prevent spandex from flying out, realize elastic elongation properties, high elasticity The effect of the stretch attribute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

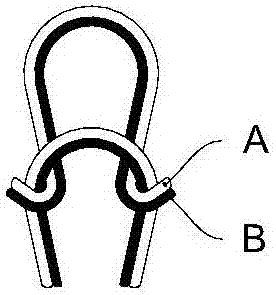

[0083] figure 1 It is a schematic diagram of the basic structure formed by the method embodiment 1 of the present invention.

[0084] figure 1 Ordinary spandex B and another non-spandex ground comb yarn A are fed into the ground comb to form loops to form two overlapped coils, one of which is a special anti-scattering structure of spandex coils.

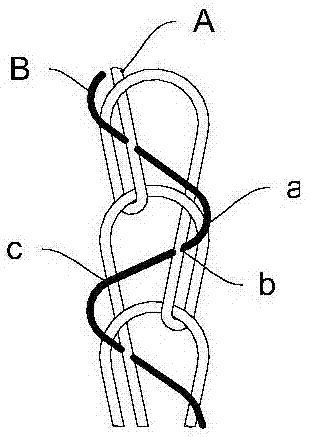

[0085] The above schematic diagram of the basic structure can be changed in many ways. According to the position of the extension line, various mesh structures such as open, closed, warp flat, and hexagonal can be formed. In circles, etc.

[0086] Straight knitting chain structure (opening and closing), is to form the basic structure that multi-comb warp knitted fabric adopts, and among the present invention, weaves through spandex or spandex-containing composite yarn (as hereinafter embodiment 2), forms multi-comb warp knitted fabric. Comb the ground network organization of warp knitted fabric, the straight knitting chain struc...

specific Embodiment approach 2

[0104] Such as Figure 34 It is a schematic diagram of the knitting structure of the multi-bar warp knitting machine in mode 2, using GB1 ( Figure 34 1) and GB2 ( Figure 34 In 1 ') two looped ground combs are fed into A non-spandex and B spandex yarns respectively, which also realizes the use of multi-comb warp knitted fabrics described in the present invention, so that the fabric obtains anti-scattering performance and Various weaving methods with good characteristics.

[0105] Circle ground comb GB1 process chain number: 1-0 / 0-1 / / full wear.

[0106] Comb in a circle GB2 process chain number: 1-0 / 0-1 / / full wear.

[0107] jacquard comb Figure 34 Middle 4 and 5, weft-inserted ground comb 6, and each flower bar 3 weave jacquard and various forms of weavable tissue respectively.

[0108] Such as Figure 35 It is a schematic diagram of the weaving implementation state of the multi-bar warp knitting machine in mode 2; through the 16 warp let-off device, the A non-spandex g...

Embodiment 2

[0116] Figure 13 Composite yarn C with spandex is used for the ground weave, with figure 1 Similarly, it can also have good anti-scattering performance.

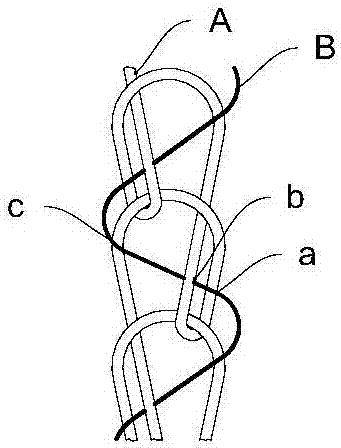

[0117] Embodiment 2 Basic structure 1: Figure 15 The spandex composite yarn C forming the ground net coil is an open straight knitting chain organization; embodiment 2 basic structure 2: Figure 16 The spandex composite yarn C forming the ground net coil is a closed-end straight knitting chain structure. According to the needs of the process, the linear knitting chain organization in which the A and B yarns are mutually open and closed can also be derived. Such as Figure 16 and Figure 17 The basic structure 1 and basic structure 2 schematic diagrams of embodiment 2 are shown, because the spandex composite yarn, Figure 18 It is a schematic diagram of the first yarn structure. Here, the core yarn B is spandex, and its draft ratio is inconsistent with that of the non-spandex yarn A, so the state of the yarn in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com