Die tool of small pack basket heating radiator

A radiator and back basket technology is applied in the field of civil radiator processing and manufacturing, which can solve the problems of weak welding, infiltration of heat conduction medium, and erosion of weld seams, and achieve the effect of saving material and labor costs, reliable service life and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

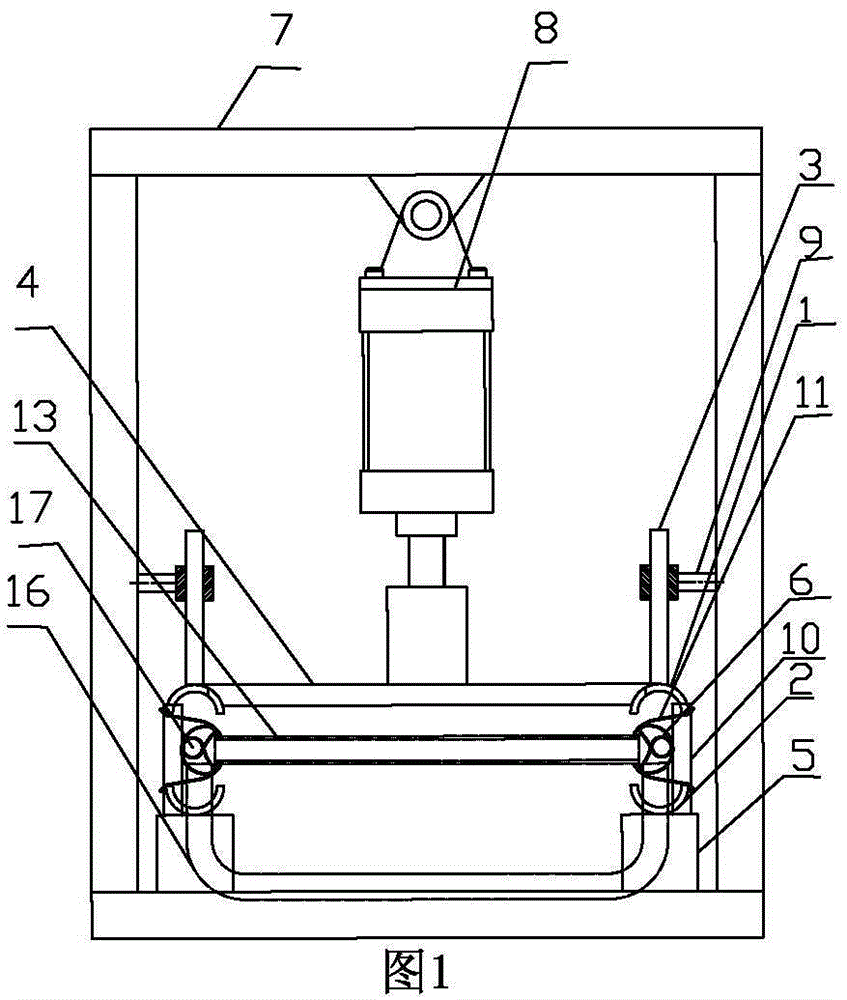

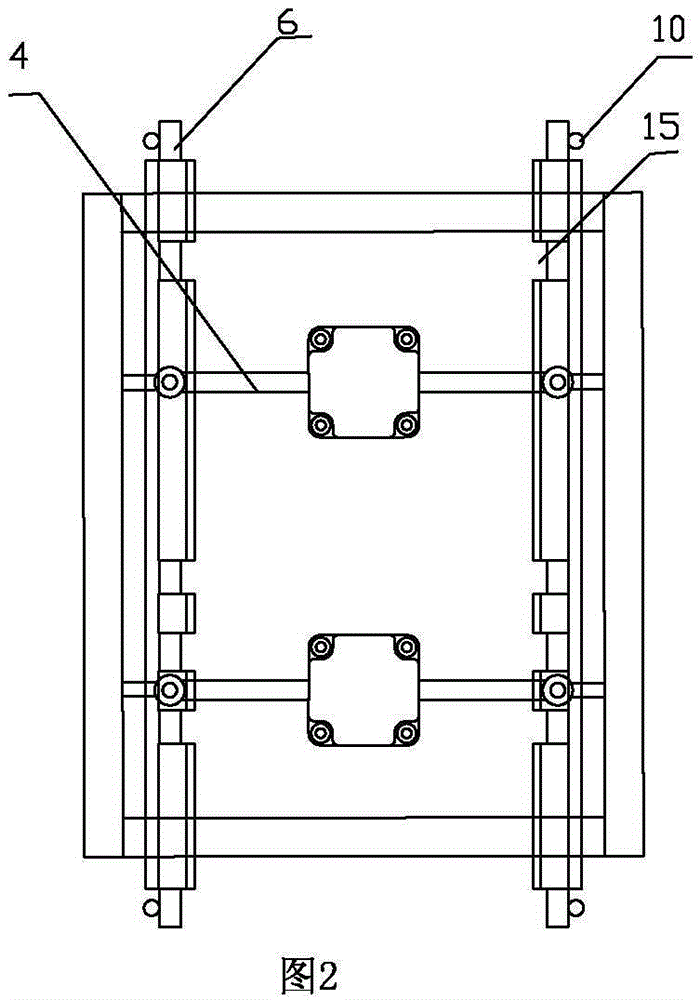

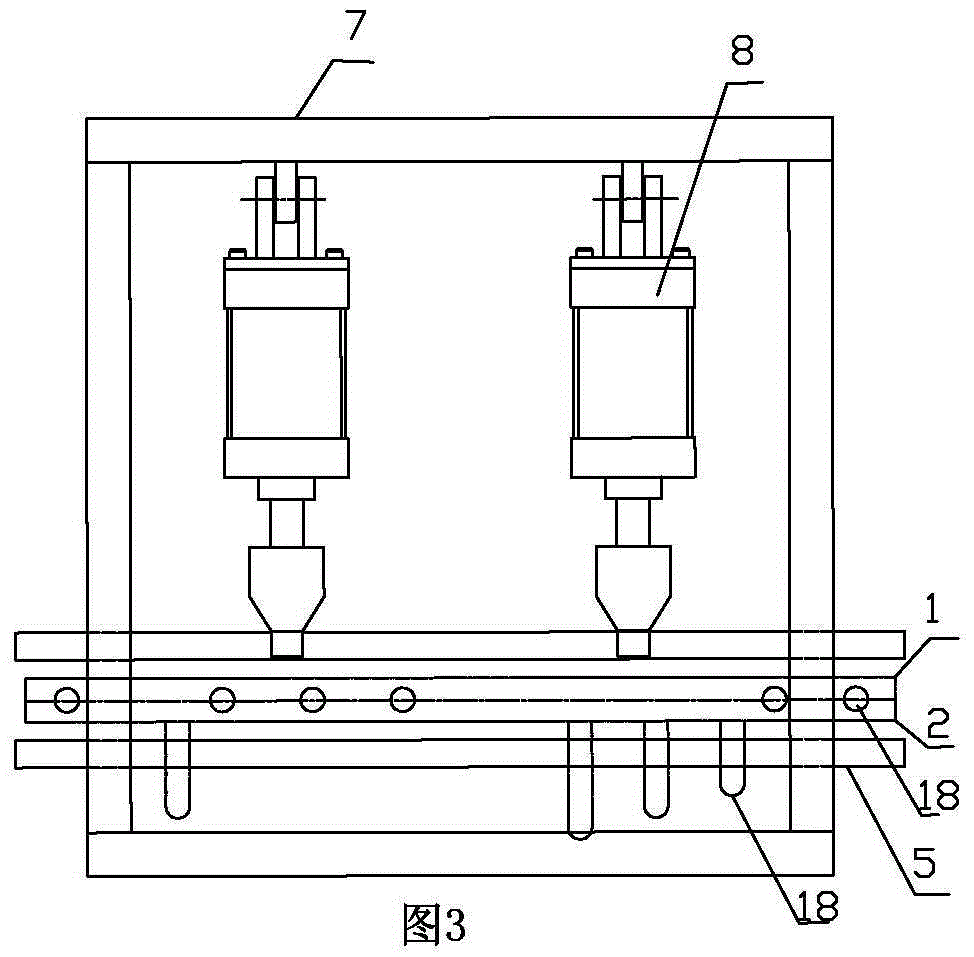

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0018] The mold tooling of the small basket type heating radiator, which includes two pairs of pressure tube arc plate joints arranged symmetrically from left to right, and the pressure tube arc plate joints include upper arc plate 1, lower arc plate 2, and guide rod shaft 3 , support plate 4, seat cushion 5, each pair of pressure tube arc plates is combined by upper arc plate 1, lower arc plate 2, and inner core tube 6, and also includes frame 7, cylinder 8, guide rod bushing 9, Positioning shaft 10, one end of cylinder 8 is connected with frame 7, the other end of cylinder 8 is connected with support plate 4, guide rod sleeve 9 is fixed on both sides of frame 7, the upper end of seat cushion 5 is connected with lower arc plate 2, and the lower end of seat cushion 5 Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com