Suture tape for surgical operation and production method thereof

A technology of surgical operation and production method, which is applied in the field of medical equipment, and can solve problems such as single thickness of wire tape, easy breakage and falling off, tissue or organ damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

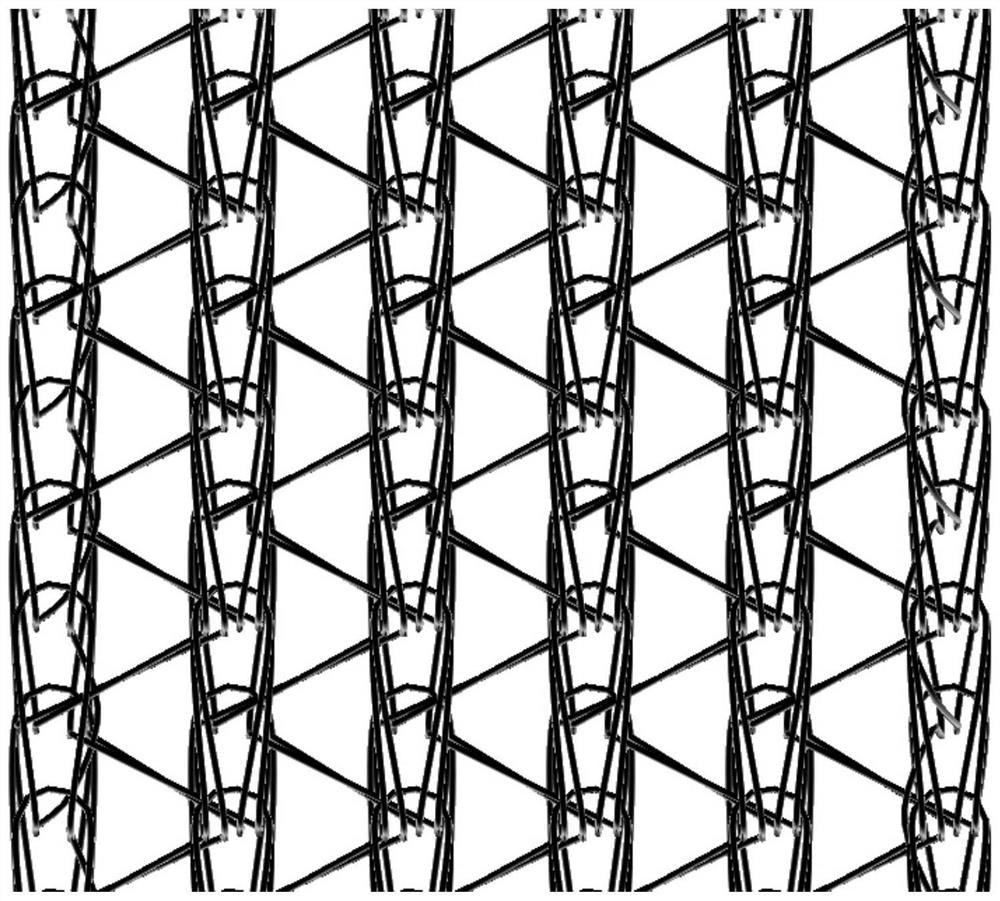

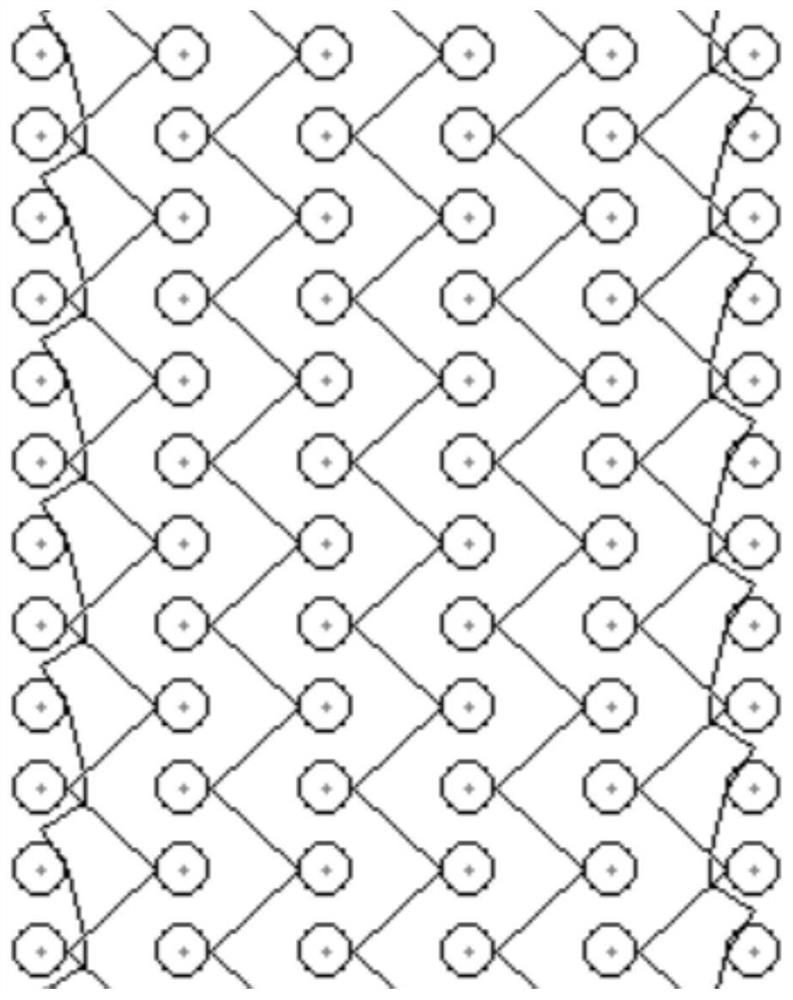

[0020] The invention discloses a production method of a thread tape for surgical operations. The full-drawn yarn is braided through a multi-layer flat structure, and the thread tapes of different widths and thicknesses are formed by changing the number of stitches and the thickness of the yarn. After post-processing, the ribbons of different colors are realized. In the present invention, the structure of the coil is as figure 2 shown. The preparation method of the thread tape of the present invention is specifically as follows: on a double-needle bed warp knitting machine, two bars are used to weave the yarn to form a two-layer warp flat structure tape, and the specifications of the yarn are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com