Alkyd resin for insulating paints and preparation method of alkyd resin

A technology of alkyd resin and insulating paint, applied in the field of resin, can solve the problems of large price increase and increase of resin cost, and achieve the effect of cost reduction, enhanced competitiveness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

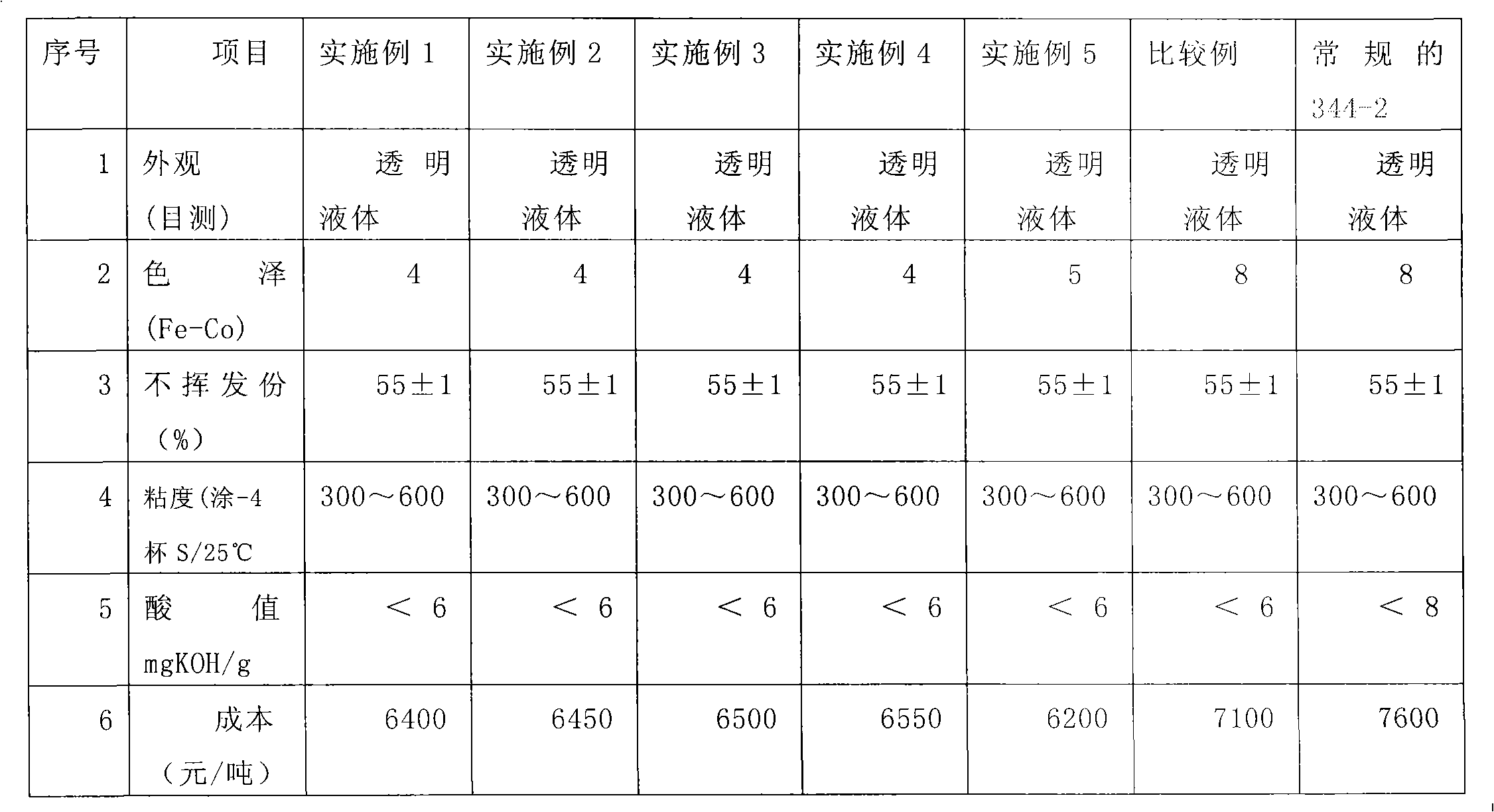

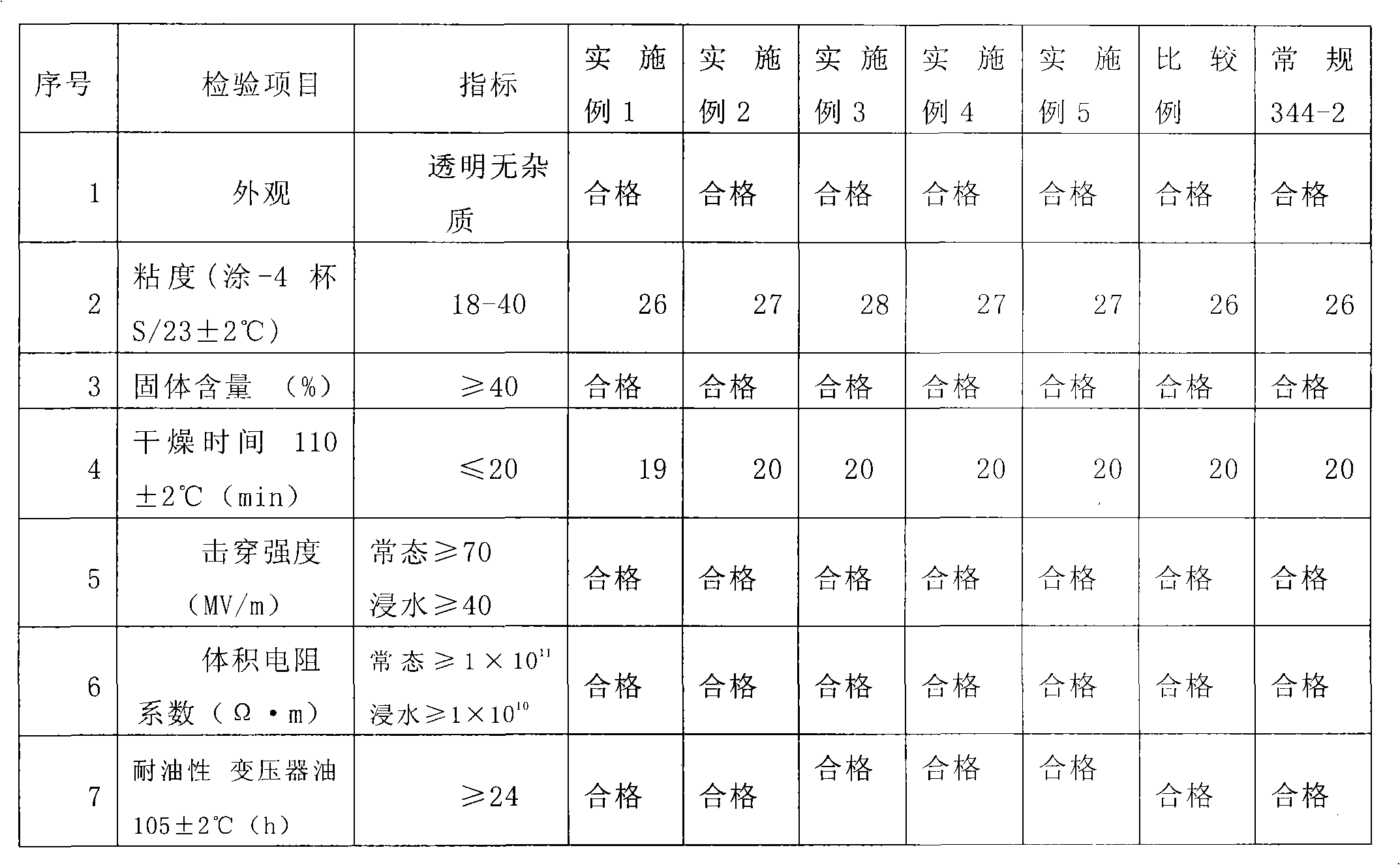

Examples

preparation example Construction

[0022] A kind of preparation method of alkyd resin for insulating varnish of the present invention comprises the following steps:

[0023] A. Primary esterification: put 21-29 parts of glycerin, 10-16 parts of stearic acid, 16-24 parts of oleic acid, 15-25 parts of crude terephthalic acid and 0.06-0.1 parts of hypophosphorous acid into the reactor, Close the feeding port, open the vent valve, start stirring at the same time as the temperature rises, heat up to 220-240°C for 2.5-3.5 hours, and control the sampling until the material is transparent;

[0024] Among them, crude terephthalic acid is the leftovers of producing purified terephthalic acid, that is, the pool material after washing. The price is very cheap at 4,200 yuan / ton, and the price of purified terephthalic acid is 8,500 yuan / ton. Use these raw materials The color of the produced resin is light, and the cost is greatly reduced. The meaning of central control refers to sampling and testing during the reaction proce...

Embodiment 1

[0035] Will be 22 parts of glycerin according to the ratio of parts by weight, 11 parts of stearic acid, 24 parts of oleic acid, 15 parts of crude terephthalic acid, plus 0.08 parts of hypophosphorous acid, drop into a stainless steel reaction kettle, seal Close the feeding port, open the vent valve, and start stirring when the temperature rises. When the temperature rises to 180°C, a large amount of water will be generated (pay attention to the expansion of the pot). Keep warm at 230-235°C for 3 hours, take a sample and control it. After the material is transparent, cool down to 200°C, add 21 parts of phthalic anhydride, 7 parts of benzoic acid, and an appropriate amount of reflux solvent. Raise the temperature to 195-205°C, keep warm until the acid value detected by the central control is below 10mgKOH / g, the Grignard viscosity is 14-18 seconds, and the reaction is over. Cool down to below 160°C, add xylene to adjust viscosity, filter and pack.

Embodiment 2

[0037] Put 22 parts of glycerin, 11 parts of stearic acid, 27 parts of oleic acid, 14 parts of crude terephthalic acid, and 0.1 parts of hypophosphorous acid into a stainless steel reaction kettle, keep it warm at 235 ° C, and after the material is transparent, Subsequent feeding ratio is: 19 parts of phthalic anhydride, 7 parts of benzoic acid, the process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com