Extraction method for natural pigment

An extraction method and natural pigment technology, applied in the field of natural pigment extraction, can solve the problems of high cost and low extraction rate, and achieve the effects of increased yield, high extraction efficiency, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

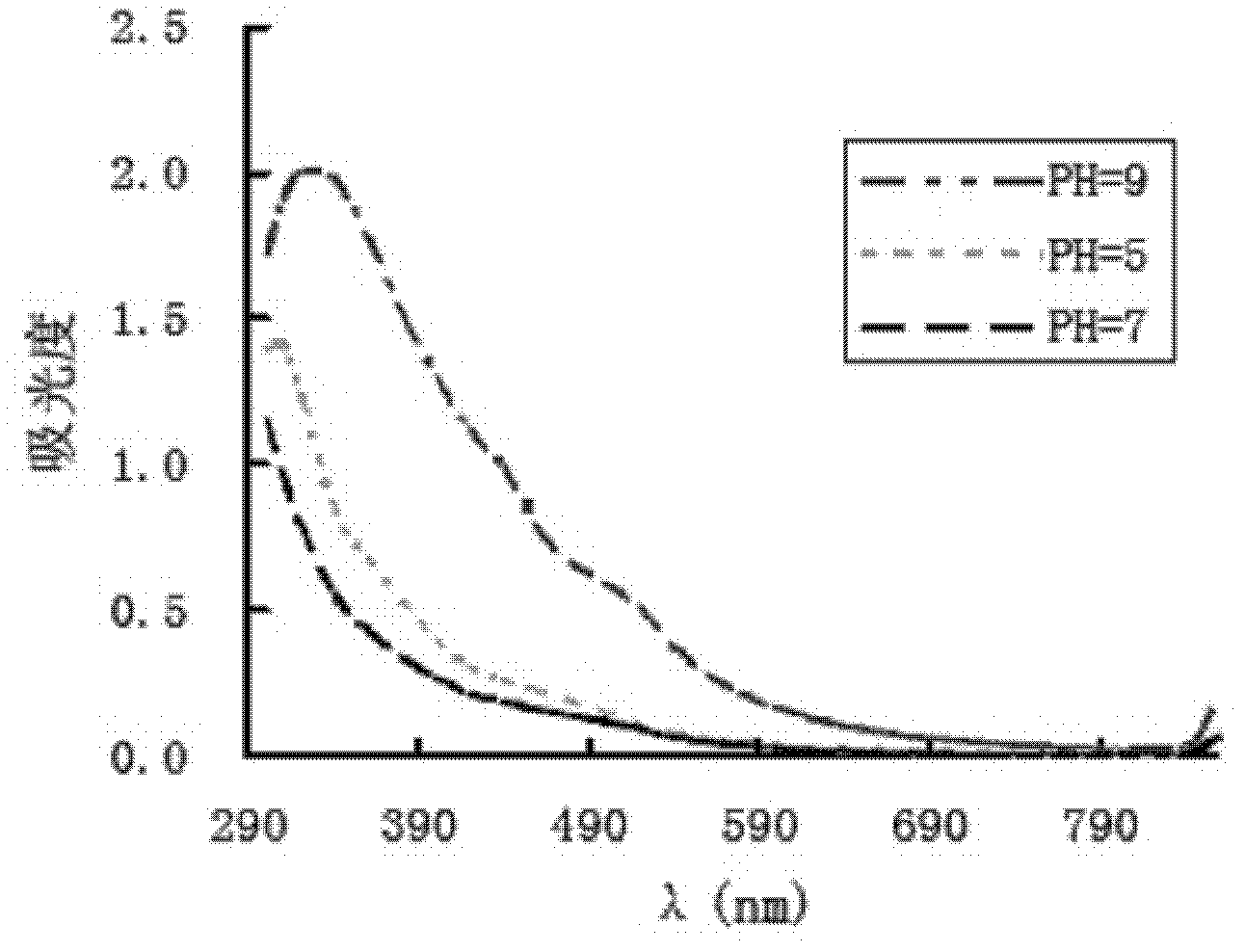

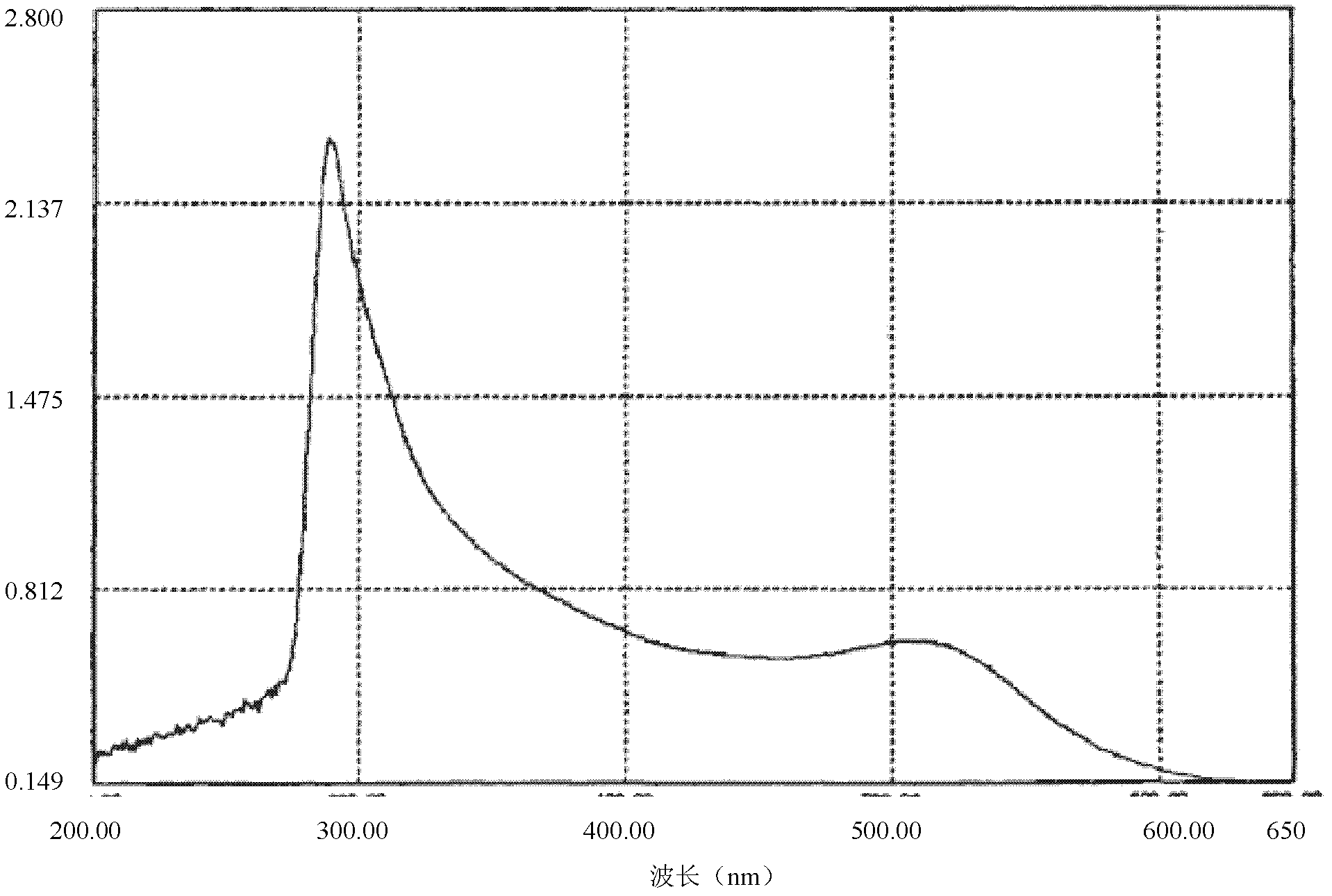

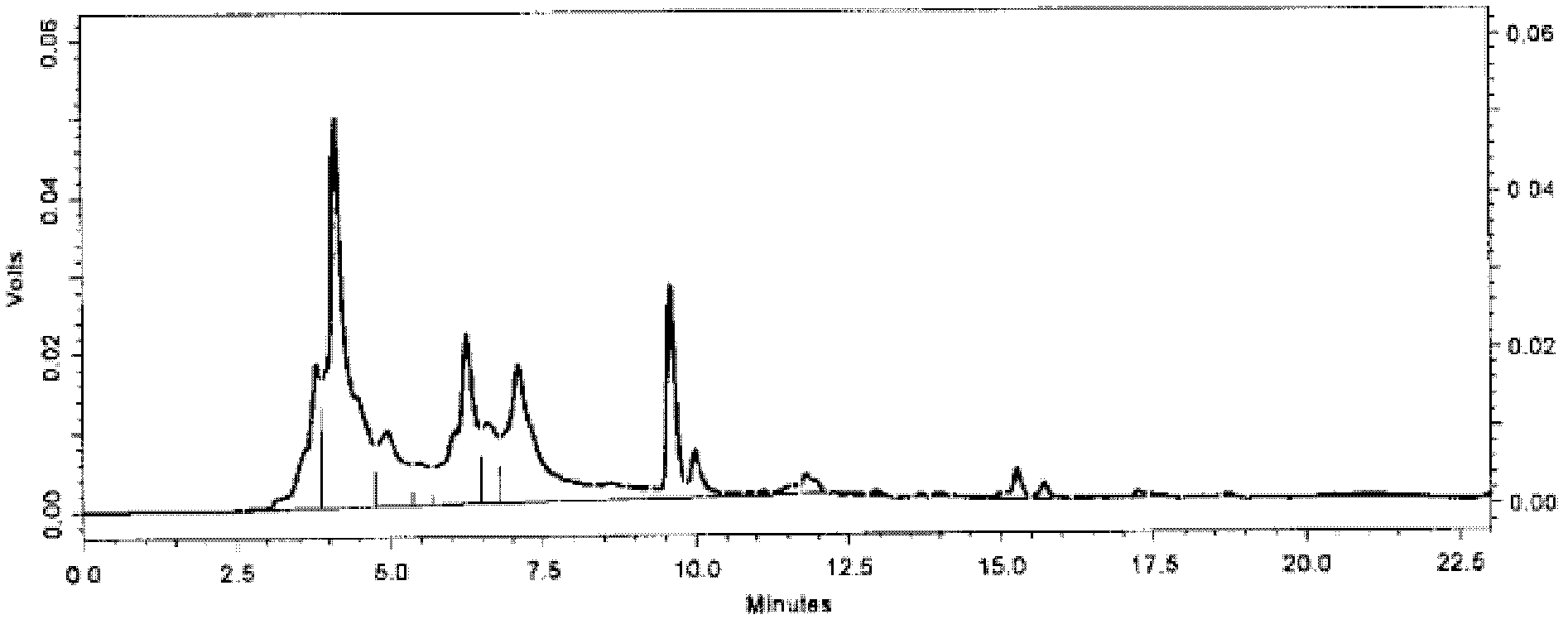

Method used

Image

Examples

Embodiment 1

[0066] 1) Take fresh chestnut shells, wash them with water, dry them, crush them, pass them through a 100-mesh sieve, and set them aside.

[0067] 2) Weigh 100 grams of chestnut shell powder, add ethanol with a volume fraction of 95%, and adjust the pH value to 2.0 with 0.1 mole per liter of hydrochloric acid, and the mass volume fraction of the solid-liquid ratio is 1:5.

[0068] 3) At room temperature, high-speed pretreatment at 10,000 rpm for 10 minutes, followed by homogeneous extraction at 3,000 rpm for 30 minutes, followed by filtration.

[0069] 4) Homogenously extract the filter residue in the above step 3) for another 5 hours at 3000 rpm, and filter.

[0070] 5) Combine the two filtrates, neutralize with 0.1 mole per liter of sodium hydroxide solution, centrifuge at 1000 rpm for 10 minutes, remove the precipitate, collect the supernatant, concentrate, freeze-dry to powder, and obtain the chestnut shell pigment 6.32 grams (brown color), pigment extraction rate 96.5%.

Embodiment 2

[0072] 1) Take fresh chestnut shells, wash them with water, dry them, crush them, pass them through a 100-mesh sieve, and set them aside.

[0073] 2) Weigh 100 grams of chestnut shell powder, add ethanol with a volume fraction of 95%, and adjust the pH value to 3.0 with 0.1 mole per liter of hydrochloric acid, and the mass volume fraction of the solid-liquid ratio is 1:10.

[0074] 3) At room temperature, high-speed pretreatment at 10,000 rpm for 20 minutes, followed by homogeneous extraction at 4,000 rpm for 60 minutes, followed by filtration.

[0075] 4) Extract the filter residue in the above step 3) homogeneously for another 7 hours at 3000 rpm, and filter.

[0076] 5) Combine the two filtrates, neutralize with 0.1 mole per liter of sodium hydroxide solution, centrifuge at 1000 rpm for 15 minutes, remove the precipitate, collect the supernatant, concentrate, freeze-dry to powder, and obtain the chestnut shell pigment 6.67 grams, the color is brown, and the pigment extract...

Embodiment 3

[0078] 1) Take fresh chestnut shells, wash them with water, dry them, crush them, pass them through a 100-mesh sieve, and set them aside.

[0079] 2) Weigh 100 grams of chestnut shell powder, add ethanol with a volume fraction of 95%, and adjust the pH value to 4.0 with 0.1 mole per liter of hydrochloric acid, and the mass volume fraction of the solid-liquid ratio is 1:7.

[0080] 3) At room temperature, high-speed pretreatment at 9000 rpm for 5 minutes, then homogeneous extraction at 4000 rpm for 45 minutes and then filtration.

[0081] 4) Extract the filter residue in the above step 3) homogeneously for 8 hours at 3000 rpm, and filter.

[0082] 5) The two filtrates were combined, neutralized with 0.1 mol per liter of sodium hydroxide, centrifuged at 1000 rpm for 5 minutes to remove the precipitate, concentrated after collecting the supernatant, freeze-dried into powder, and obtained 6.15 grams of chestnut shell pigment (the color is brown), and the pigment extraction rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com