Grape-skin pigment and extraction process for same

A grape skin pigment and extraction process technology, which is applied in the field of natural pigment extraction, can solve the problems of long extraction time, increased extraction cost, low economic applicability, etc. in the optimized process, and achieves uniform extraction effect, thorough extraction and good water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

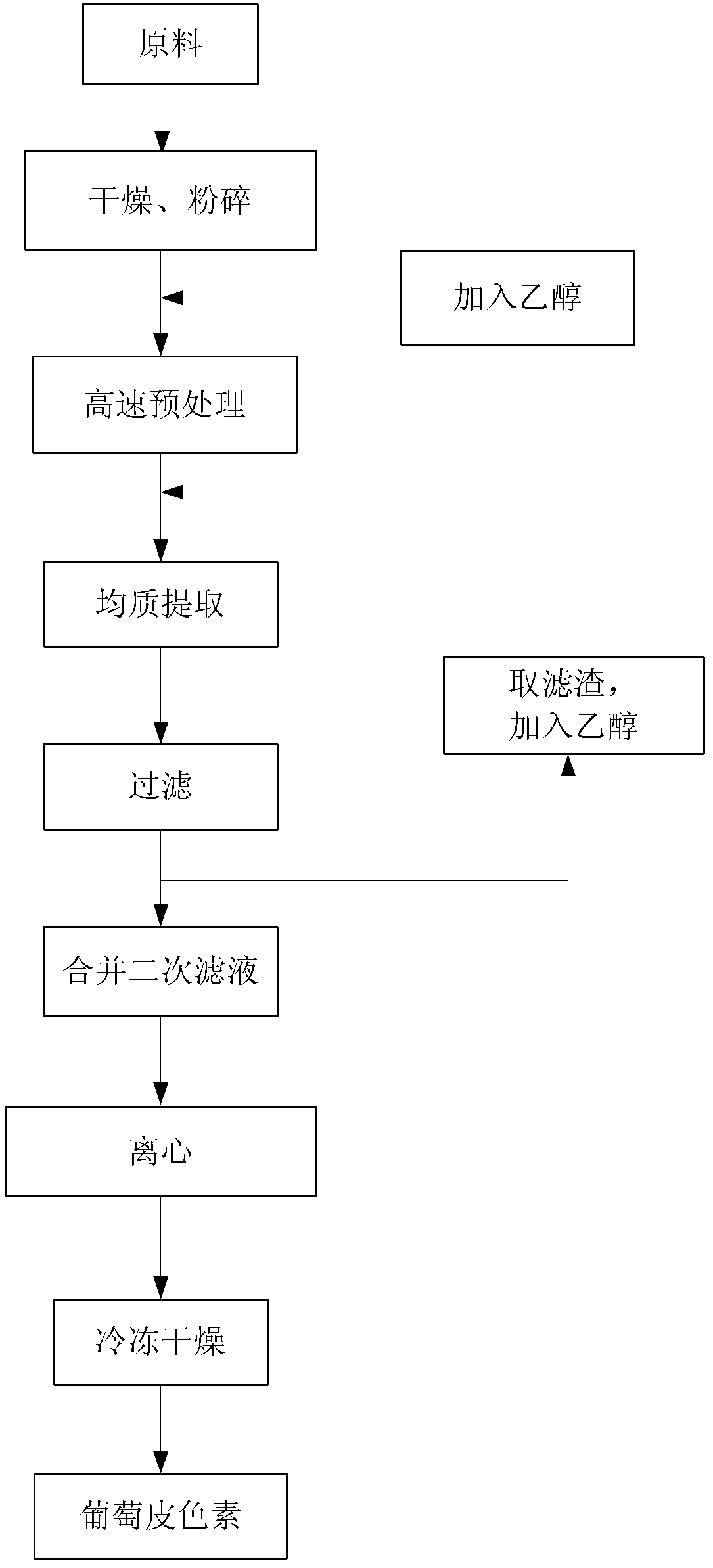

Method used

Image

Examples

Embodiment 1

[0036] 1) Take the fresh skin, wash it with water, dry it to constant weight, and finally crush it through a 100-mesh sieve to make grape skin powder. Weigh 100 grams of the above grape skin powder and set aside.

[0037] 2) Add 95wt% ethanol (grape skin powder: 95wt% ethanol = 1g: 5mL), and adjust the pH value to 2.0 with 0.1 mol / liter citric acid solution, and pretreat at room temperature for 5 minutes at a high speed of 10000 rpm, Then, extract homogeneously at 3000 rpm for 30 minutes and then filter.

[0038] 3) Collect the filtrate, add 95wt% ethanol to the filter residue (filter residue: 95wt% ethanol = 1g: 5mL), and adjust the pH value to 2.0 with 0.1 mol / liter citric acid solution, and homogenize at room temperature at 3000 rpm Filter after 30 minutes of extraction.

[0039] 4) Combine the two filtrates, centrifuge at 1000 rpm for 10 minutes at room temperature, remove the precipitate, collect the supernatant and freeze-dry it into a powder to obtain 3.26 grams of gra...

Embodiment 2

[0041] 1) Take fresh skin, wash it with water, dry it to constant weight, crush it through a 100-mesh sieve to make grape skin powder, weigh 100 grams of the above grape skin powder, and set aside.

[0042] 2) Add 95wt% ethanol (grape skin powder: 95wt% ethanol = 1g: 7mL), and adjust the pH value to 3.0 with 0.1 mol / liter citric acid solution, and pretreat at room temperature for 10 minutes at a high speed of 10000 rpm, Then, extract homogeneously at 3000 rpm for 20 minutes and then filter.

[0043] 3) Collect the filtrate, add 95wt% ethanol to the filter residue (filter residue: 95wt% ethanol = 1g: 7mL), and adjust the pH value to 3.0 with 0.1 mol / L citric acid solution, and extract homogeneously at room temperature at 3000 rpm Filter after 20 minutes.

[0044] 4) Combine the two filtrates, centrifuge at 1000 rpm for 15 minutes at room temperature, remove the precipitate, collect the supernatant and freeze-dry it into a powder to obtain 3.35 grams of grape skin pigment, colo...

Embodiment 3

[0046]1) Take fresh skin, wash it with water, dry it to constant weight, crush it through a 100-mesh sieve to make grape skin powder, weigh 100 grams of the above grape skin powder, and set aside.

[0047] 2) Add 95wt% ethanol (grape skin powder: 95wt% ethanol = 1g: 10mL), and adjust the pH value to 4.0 with 0.1 mol / liter citric acid solution, and pretreat at room temperature for 10 minutes at a high speed of 10000 rpm, Then, extract homogeneously at 3000 rpm for 10 minutes and then filter.

[0048] 3) Collect the filtrate, add 95wt% ethanol to the filter residue (filter residue: 95wt% ethanol = 1g: 10mL), and adjust the pH value to 4.0 with 0.1 mol / L citric acid solution, and extract homogeneously at 3000 rpm at room temperature Filter after 10 minutes.

[0049] 4) The two filtrates were combined, and centrifuged at 1000 rpm for 15 minutes at room temperature to remove the precipitate. After collecting the supernatant, freeze-dried into a powder to obtain 3.31 grams of grape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com