Technology for extracting pigments from grape peels

A technology of grape skin pigment and extraction process, applied in the field of extraction of natural pigments, can solve the problems of increased extraction cost, increased cost of post-solvent, low economic applicability, etc., and achieves uniform extraction effect, good appearance and color, and good water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

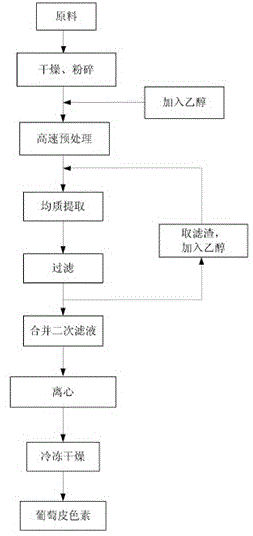

Method used

Image

Examples

Embodiment 1

[0033] 1) Take the fresh skin, wash it with water, dry it to constant weight, and finally crush it through a 100-mesh sieve to make grape skin powder. Weigh 100 grams of the above grape skin powder and set aside.

[0034] 2) Add 95wt% ethanol (grape skin powder: 95wt% ethanol = 1g: 5mL), and adjust the pH value to 2.0 with 0.1 mol / liter citric acid solution, and pretreat at room temperature for 5 minutes at a high speed of 10000 rpm, Then, extract homogeneously at 3000 rpm for 30 minutes and then filter.

[0035] 3) Collect the filtrate, add 95wt% ethanol to the filter residue (filter residue: 95wt% ethanol = 1g: 5mL), and adjust the pH value to 2.0 with 0.1 mol / liter citric acid solution, and homogenize at room temperature at 3000 rpm Filter after 30 minutes of extraction.

[0036] 4) Combine the two filtrates, centrifuge at 1000 rpm for 10 minutes at room temperature, remove the precipitate, collect the supernatant and freeze-dry it into a powder to obtain 3.26 grams of gra...

Embodiment 2

[0038] 1) Take fresh skin, wash it with water, dry it to constant weight, crush it through a 100-mesh sieve to make grape skin powder, weigh 100 grams of the above grape skin powder, and set aside.

[0039] 2) Add 95wt% ethanol (grape skin powder: 95wt% ethanol = 1g: 7mL), and adjust the pH value to 3.0 with 0.1 mol / liter citric acid solution, and pretreat at room temperature for 10 minutes at a high speed of 10000 rpm, Then, extract homogeneously at 3000 rpm for 20 minutes and then filter.

[0040] 3) Collect the filtrate, add 95wt% ethanol to the filter residue (filter residue: 95wt% ethanol = 1g: 7mL), and adjust the pH value to 3.0 with 0.1 mol / L citric acid solution, and extract homogeneously at room temperature at 3000 rpm Filter after 20 minutes.

[0041] 4) Combine the two filtrates, centrifuge at 1000 rpm for 15 minutes at room temperature, remove the precipitate, collect the supernatant and freeze-dry it into a powder to obtain 3.35 grams of grape skin pigment, colo...

Embodiment 3

[0043] 1) Take fresh skin, wash it with water, dry it to constant weight, crush it through a 100-mesh sieve to make grape skin powder, weigh 100 grams of the above grape skin powder, and set aside.

[0044] 2) Add 95wt% ethanol (grape skin powder: 95wt% ethanol = 1g: 10mL), and adjust the pH value to 4.0 with 0.1 mol / liter citric acid solution, and pretreat at room temperature for 10 minutes at a high speed of 10000 rpm, Then, extract homogeneously at 3000 rpm for 10 minutes and then filter.

[0045] 3) Collect the filtrate, add 95wt% ethanol to the filter residue (filter residue: 95wt% ethanol = 1g: 10mL), and adjust the pH value to 4.0 with 0.1 mol / L citric acid solution, and extract homogeneously at 3000 rpm at room temperature Filter after 10 minutes.

[0046] 4) The two filtrates were combined, and centrifuged at 1000 rpm for 15 minutes at room temperature to remove the precipitate. After collecting the supernatant, freeze-dried into a powder to obtain 3.31 grams of grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com