Preparation method of coconut nutrient peanut oil

A technology of peanut oil and nutrition, which is applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc. It can solve the problems of low raw material utilization rate and low quality, and achieve the effect of thorough extraction, low production cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

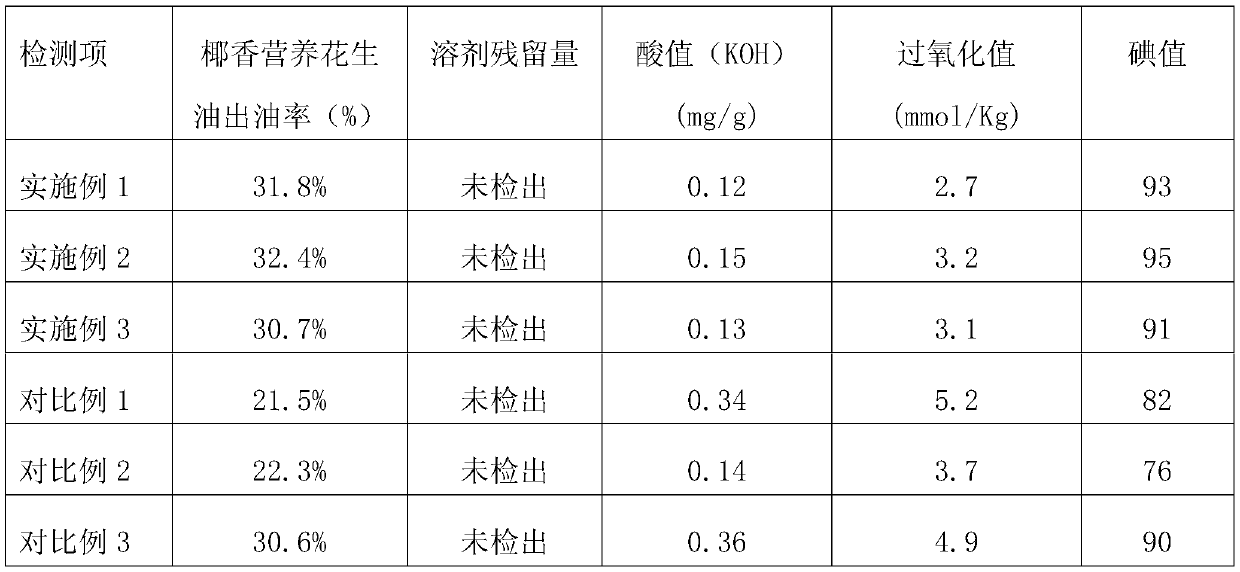

Examples

Embodiment 1

[0030] A preparation method of coconut-flavored nutritious peanut oil, comprising the steps of:

[0031] (1) Raw material pretreatment: mix peanut kernels and coconut meat according to the weight ratio of 3:1, then add sodium chloride solution with a mass fraction of 0.8%, soak in ultrasonic for 2.5h, take out, rinse with cold water, and drain Standby; where the ultrasonic power density is 60-80W / L, and the ultrasonic frequency is 15-25kHz;

[0032] (2) Repeated freezing and thawing: Put the pretreated raw materials obtained in step (1) into a crushing equipment for crushing until they can pass through a 40-mesh sieve, freeze the crushed raw materials to -15°C to -20°C, and then place them at 40°C Thaw quickly, so repeated freezing and thawing 4 times;

[0033] (3) Low-temperature drying: dry the raw material obtained in step (2) by freezing and thawing at 40-60° C. until the moisture percentage in the raw material is 4-7%;

[0034] (4) Supercritical carbon dioxide extractio...

Embodiment 2

[0037] A preparation method of coconut-flavored nutritious peanut oil, comprising the steps of:

[0038] (1) Raw material pretreatment: Mix peanut kernels and coconut meat according to the ratio of 2:1 by weight, then add sodium chloride solution with a mass fraction of 0.5%, soak in ultrasonic for 2 hours, take out, rinse with cold water, drain and set aside ; The ultrasonic power density is 60-80W / L, and the ultrasonic frequency is 15-25kHz;

[0039] (2) Repeated freezing and thawing: Put the pretreated raw materials obtained in step (1) into a crushing equipment for crushing until they can pass through a 40-mesh sieve, freeze the crushed raw materials to -15°C to -20°C, and then place them at 40°C Thaw quickly, so repeated freezing and thawing 3 times;

[0040] (3) Low-temperature drying: dry the raw material obtained in step (2) by freezing and thawing at 40-60° C. until the moisture percentage in the raw material is 4-7%;

[0041] (4) Supercritical carbon dioxide extrac...

Embodiment 3

[0044] A preparation method of coconut-flavored nutritious peanut oil, comprising the steps of:

[0045] (1) Raw material pretreatment: mix peanut kernels and coconut meat according to the weight ratio of 5:1, then add sodium chloride solution with a mass fraction of 1%, soak in ultrasonic for 3 hours, take it out, rinse with cold water, drain and set aside ; The ultrasonic power density is 60-80W / L, and the ultrasonic frequency is 15-25kHz;

[0046] (2) Repeated freezing and thawing: Put the pretreated raw materials obtained in step (1) into a crushing equipment for crushing until they can pass through a 40-mesh sieve, freeze the crushed raw materials to -15°C to -20°C, and then place them at 40°C Thaw quickly, so repeated freezing and thawing 5 times;

[0047] (3) Low-temperature drying: dry the raw material obtained in step (2) by freezing and thawing at 40-60° C. until the moisture percentage in the raw material is 7%;

[0048] (4) Supercritical carbon dioxide extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com