Resource treatment method of oil-containing sludge

A treatment method and technology of a sewage treatment plant are applied in the field of resource treatment of oily sludge, which can solve the problems of increased sewage discharge burden of enterprises, difficult treatment technology of oily sludge, and complicated equipment, so as to achieve harmless treatment and resource utilization. Chemical utilization, superior solubility, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

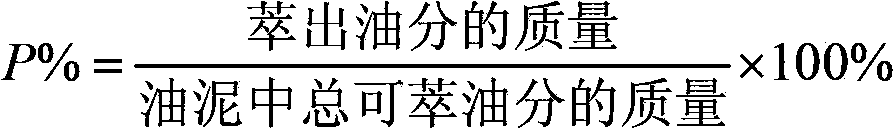

Embodiment 1

[0040]The solvent formula is as follows: distillate oil with a boiling range of naphtha in the boiling range of 110-125°C is selected as the main agent of the extraction solvent, accounting for 85%; It is a distillate oil at 80-100°C, accounting for 5.0%, forming a composite extractant. After mechanical dehydration, the oily sludge produced by a refinery sewage treatment plant has a water content of 65.0wt% and an oil content of 20.0wt%. The mass ratio of the extractant to the oily sludge is 1:1. The oily sludge is sent to the extraction tank. At 120°C, the pressure is 0.20 MPa and the extractant is mixed for extraction. The extraction time is 20 minutes. After the extraction is completed, the solid-liquid The mixture is sent to the centrifugal separator, the separated liquid phase directly enters the crude oil processing system device, and the solid phase enters the paddle-type sludge dryer, and is dried at a temperature of 180°C and a pressure of 80KPa (absolute pressure) fo...

Embodiment 2

[0044] The solvent formula is as follows: distillate oil with a boiling range of naphtha with a boiling range of 110-125°C is selected as the main agent of the extraction solvent, accounting for 90%; distillate oil with a boiling range of 140-150°C is selected as an auxiliary agent, accounting for 5%; It is a distillate oil at 80-100°C, accounting for 5.0%, forming a composite extractant. The oily sludge produced by a refinery sewage treatment plant has a water content of 75.0wt% and an oil content of 15.0wt% after mechanical dehydration. The mass ratio of the extractant to the oily sludge is 5:1. The oily sludge is sent to the extraction tank. At 140°C, the pressure is 0.40MPa and the extractant is mixed for extraction. The extraction time is 40min. After the extraction is completed, the solid-liquid The mixture is sent to the centrifugal separator, the separated liquid phase directly enters the crude oil processing system device, and the solid phase enters the paddle-type sl...

Embodiment 3

[0048] The solvent formula is as follows: distillate oil with a boiling range of naphtha with a boiling range of 110-125°C is selected as the main agent of the extraction solvent, accounting for 95%; distillate oil with a boiling range of 140-150°C is selected as an auxiliary agent, accounting for 2.5%; It is a distillate oil at 80-100°C, accounting for 2.5%, forming a composite extractant. The oily sludge produced by a refinery sewage treatment plant has a water content of 85.0wt% and an oil content of 9.0wt% after mechanical dehydration. The mass ratio of the extractant to the oily sludge is 15:1. The oily sludge is sent to the extraction tank. At 160°C, the pressure is 0.50 MPa and the extractant is mixed for extraction. The extraction time is 60 minutes. After the extraction is completed, the solid-liquid The mixture is sent to the centrifugal separator, the separated liquid phase directly enters the crude oil processing system device, and the solid phase enters the paddle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com