Method for preparing high-purity rubidium carbonate

A high-purity technology of rubidium carbonate, applied in chemical instruments and methods, rubidium/cesium/francium compounds, alkali metal compounds, etc., can solve the problems of difficult separation of two phases, waste of extraction agent, low extraction efficiency, etc., and achieve extraction Thorough, high recovery and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

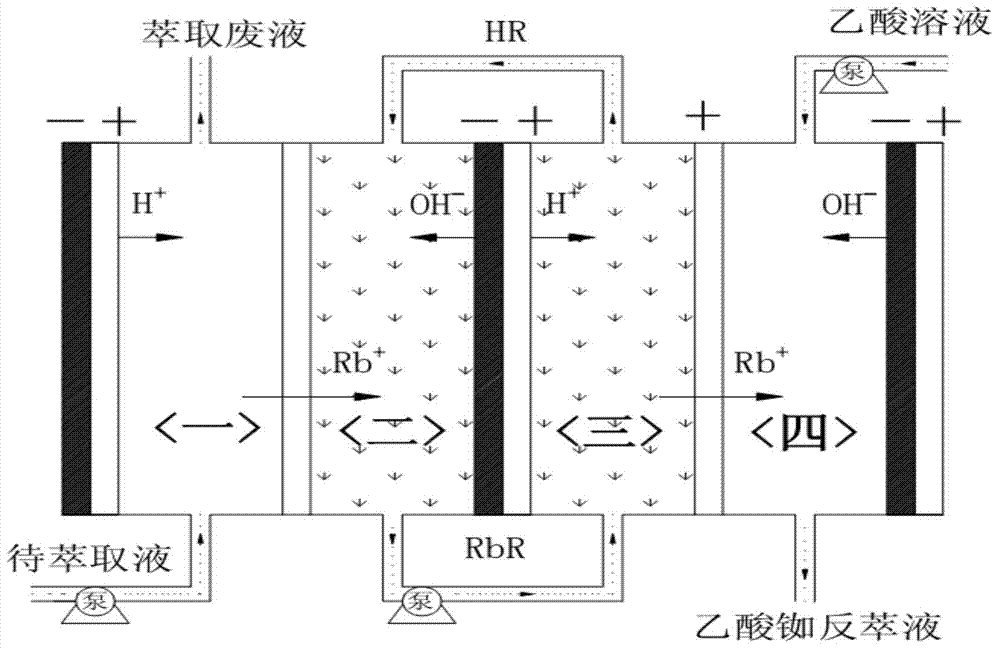

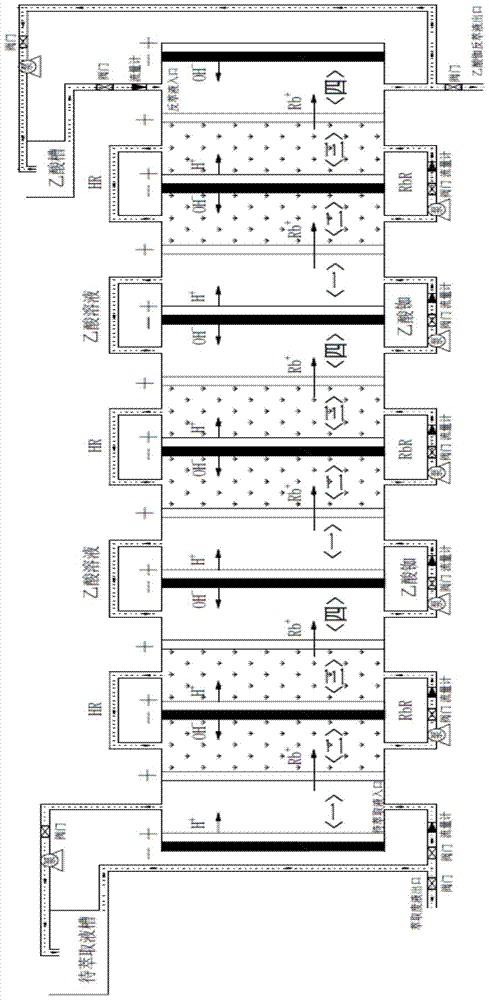

Method used

Image

Examples

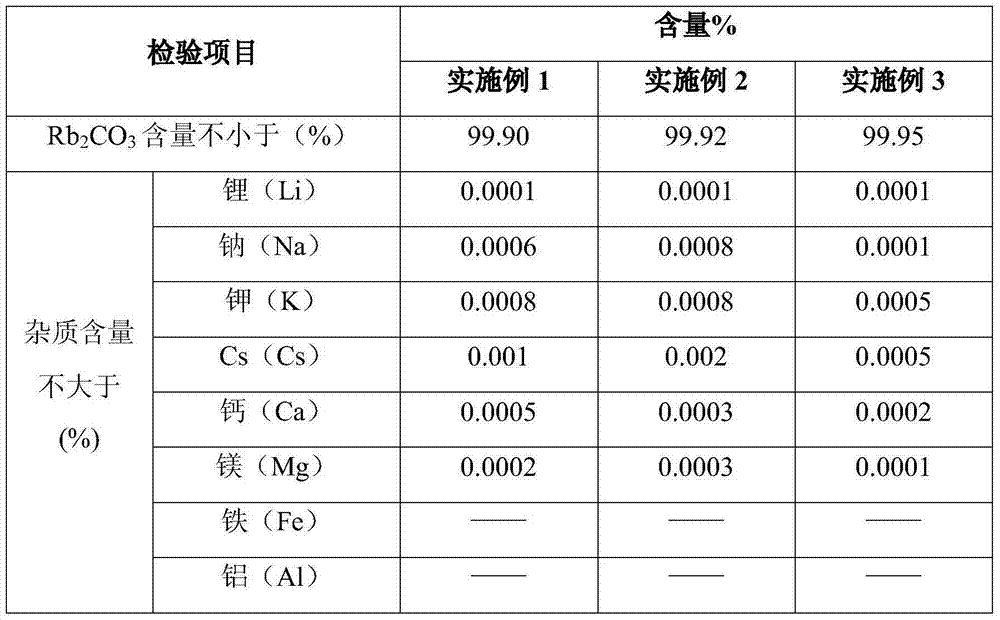

Embodiment 1

[0045] A method for preparing high-purity rubidium carbonate, the raw material is rubidium-containing waste liquid after extracting cesium with the acid leaching solution after leaching cesium garnet with sulfuric acid, and the steps are as follows:

[0046] (1) Get 13t of rubidium-containing waste liquid, after testing, the metal ion content is as follows: Cs + 0.02%, Rb + 1.89%, K + 0.54%, Na + 0.12%, Li + 0.15%, Al 3+ 0.003%, Fe 3+ 0.008%, Mg 2+ 0.06%, Ca 2+ 0.25%, Ba 2+ <0.0001%, concentrated to 1t by heating in a reactor.

[0047] (2) Add lime slurry to the concentrated solution, adjust the pH to 11.5, stir for five minutes, leave to react for 1 hour, and filter;

[0048] (3) Add 5% sulfuric acid solution to the filtrate obtained in step (2), adjust the pH to 6.0-6.5, stir for five minutes, leave to react for 1 hour, and filter;

[0049] (4) Add 10% sodium carbonate solution to the filtrate obtained by filtering in step (3), adjust the pH to 7.5-8.0, stir for fi...

Embodiment 2

[0058] A method for preparing high-purity rubidium carbonate, the raw material is rubidium sulfate and rubidium chloride mixed mother liquor, the steps are as follows:

[0059] (1) Get 6.41t rubidium sulfate and rubidium chloride mixed mother liquor, after testing, metal ion content is as follows: Cs + 0.01%, Rb + 2.37%, K + 1.23%, Na + 0.85%, Li + 0.31%, Al 3+ 0.04%, Fe 3+ 0.009%, Mg 2+ 0.001%, Ca 2+ 0.08%, Ba 2+ <0.0001%, concentrated to 1t by heating in a reactor.

[0060] (2) Add lime slurry to the concentrated solution, adjust the pH to 11.5, stir for ten minutes, leave to react for half an hour, and filter;

[0061] (3) Add 10% sulfuric acid solution to the filtrate obtained in step (2), adjust the pH to 6.0-6.5, stir for ten minutes, leave to react for half an hour, and filter;

[0062] (4) Add 8% sodium carbonate solution to the filtrate obtained by filtering in step (3), adjust the pH to 7.5-8.0, stir for ten minutes, and filter after standing for half an ho...

Embodiment 3

[0071] A method for preparing high-purity rubidium carbonate, the selected raw material is rubidium chloride and rubidium carbonate mixed mother liquor, the steps are as follows:

[0072] (1) Get 20t rubidium chloride and rubidium carbonate mixed mother liquor, after testing, metal ion content is as follows: Cs + 0.018%, Rb + 0.85%, K + 1.34%, Na + 0.03%, Li + 0.08%, Al 3+ 3+ 2+ 0.02%, Ca 2+ 2+ <0.0001%, concentrated to 1t by heating in a reactor.

[0073] (2) Add lime slurry to the concentrated solution, adjust the pH to 11.5, stir for five minutes, leave to react for half an hour, and filter;

[0074] (3) Add 15% sulfuric acid solution to the filtrate obtained in step (2), adjust the pH to 6.0-6.5, stir for five minutes, leave to react for half an hour, and filter;

[0075] (4) Add 5% sodium carbonate solution to the filtrate obtained by filtering in step (3), adjust the pH to 7.5-8.0, stir for five minutes, and filter after standing for half an hour to obtain the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com