Patents

Literature

51 results about "Rubidium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubidium carbonate, Rb₂CO₃, is a convenient compound of rubidium; it is stable, not particularly reactive, and readily soluble in water, and is the form in which rubidium is usually sold.

Production process for lithium-silicate-system compound

ActiveUS20110291055A1Low environmental loadKeep down eliminationNon-metal conductorsSilicaRubidium carbonateLithium carbonate

The present invention is one which provides a production process for lithium-silicate-system compound, the production process being characterized in that: a lithium-silicate compound being expressed by Li2SiO3 is reacted with a substance including at least one member of transition-metal elements that is selected from the group consisting of iron and manganese at 400-650° C. in a molten salt of a carbonate mixture comprising lithium carbonate and at least one member of alkali-metal carbonates that is selected from the group consisting of potassium carbonate, sodium carbonate, rubidium carbonate and cesium carbonate in a mixed-gas atmosphere including carbon dioxide and a reducing gas; and a positive-electrode active material for lithium-ion secondary battery that comprises a lithium-silicate-system compound being obtained by the aforesaid process.In accordance with the present invention, it becomes feasible to produce lithium-silicate-system materials, which are useful as positive-electrode active materials for lithium-ion secondary battery, and the like, by means of relatively simple and easy means.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

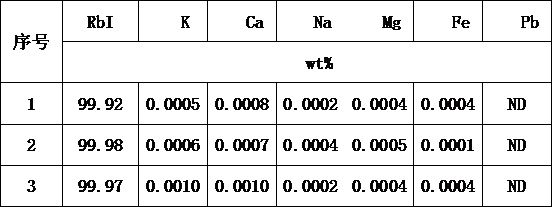

Method of preparing high-purity cesium carbonate and high-purity rubidium carbonate

The invention relates to a method of preparing high-purity cesium carbonate and high-purity rubidium carbonate. According to the content of rubidium and cesium in mixed alum, almost potassium in alum is removed by a recrystallizing method, so that the mixed alum meets the index which is appropriate for extraction separation and is then extracted and separated. By fully utilizing the advantages of recrystallization and extraction separation, overcoming the defects and organically combining the two, the high-purity cesium carbonate and high-purity rubidium carbonate are prepared by the most efficient and economical method. The method of recrystallizing and extracting provided by the invention can be used for preparing high-purity cesium carbonate and high-purity rubidium carbonate in high price by using low price mixed alum as a raw material, so that the cost is saved and the resources are protected.

Owner:凌庄坤

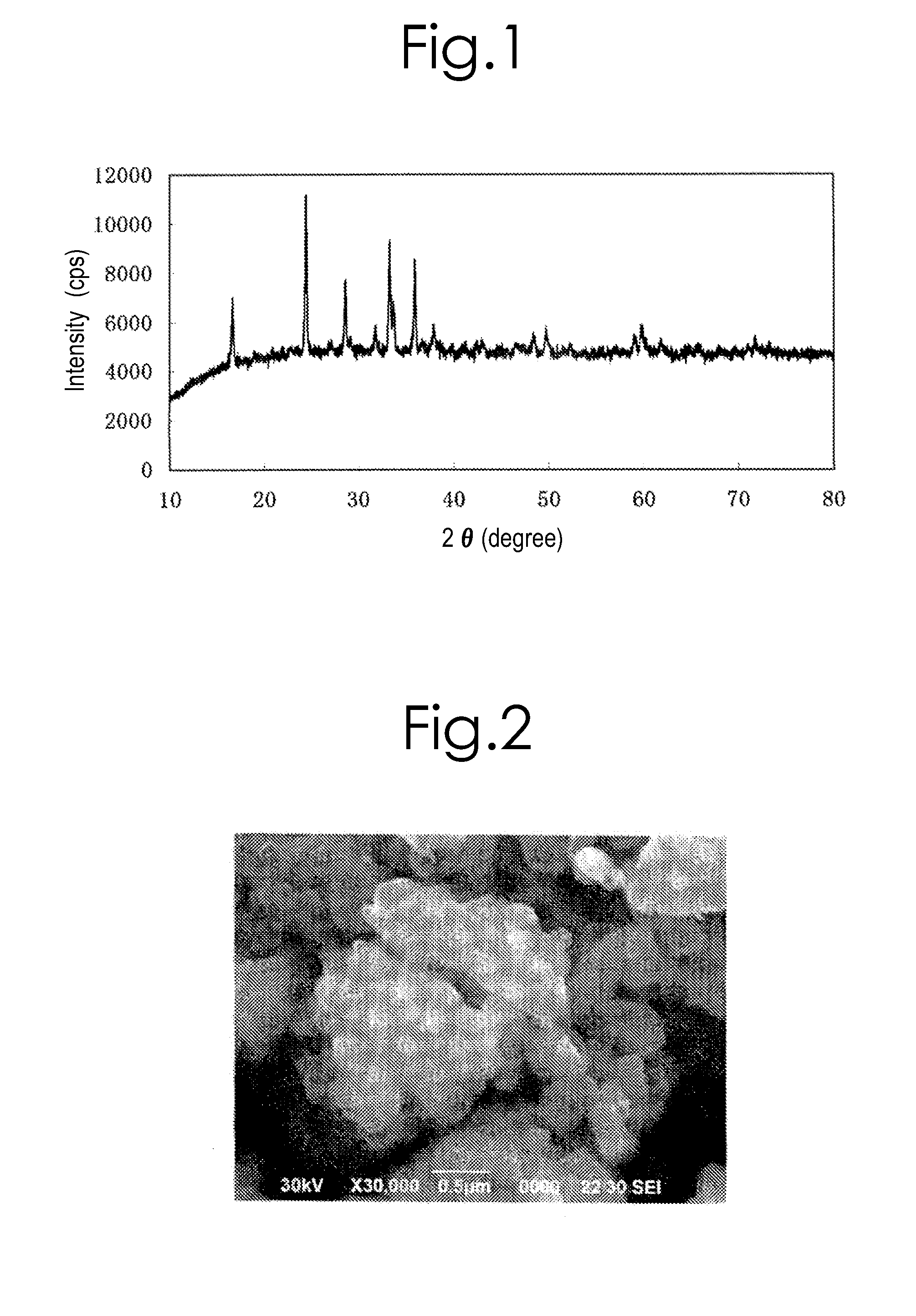

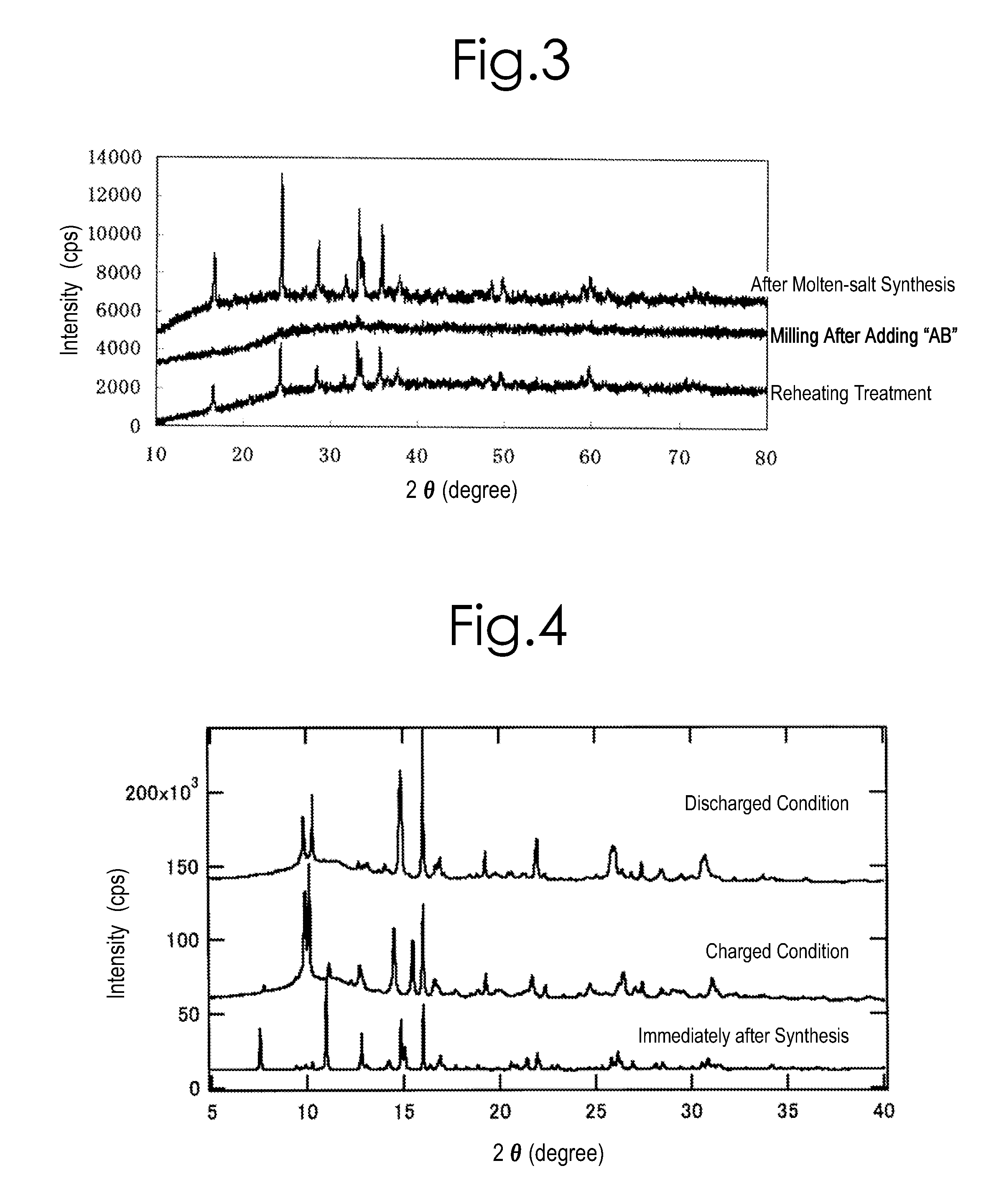

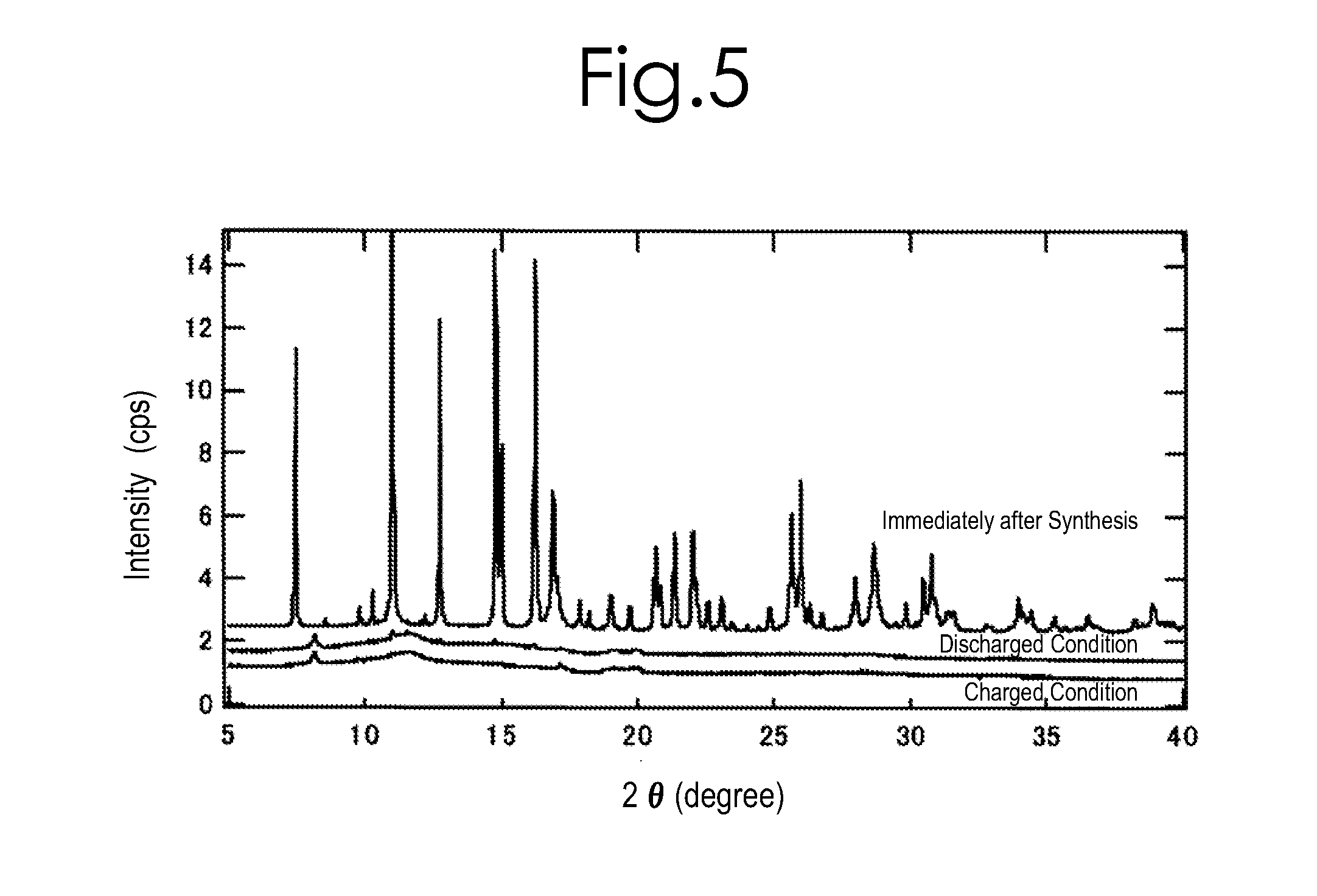

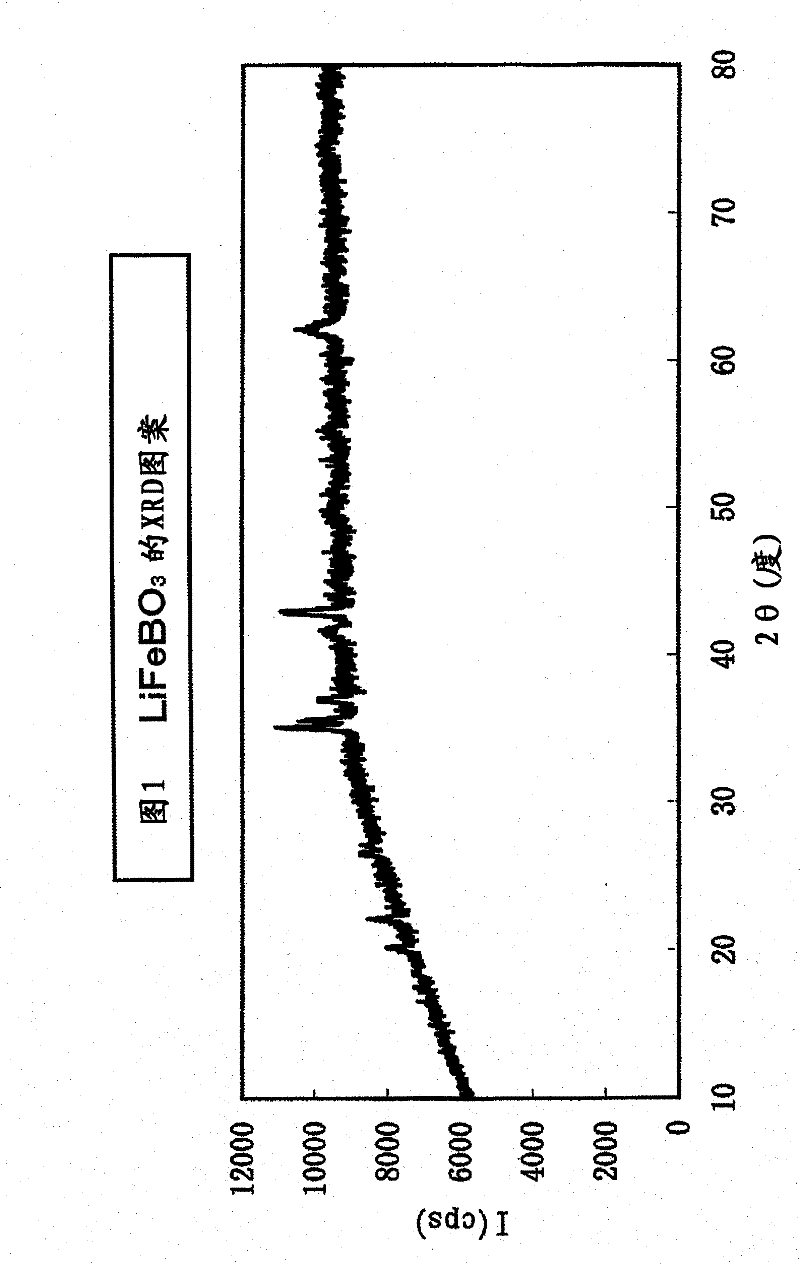

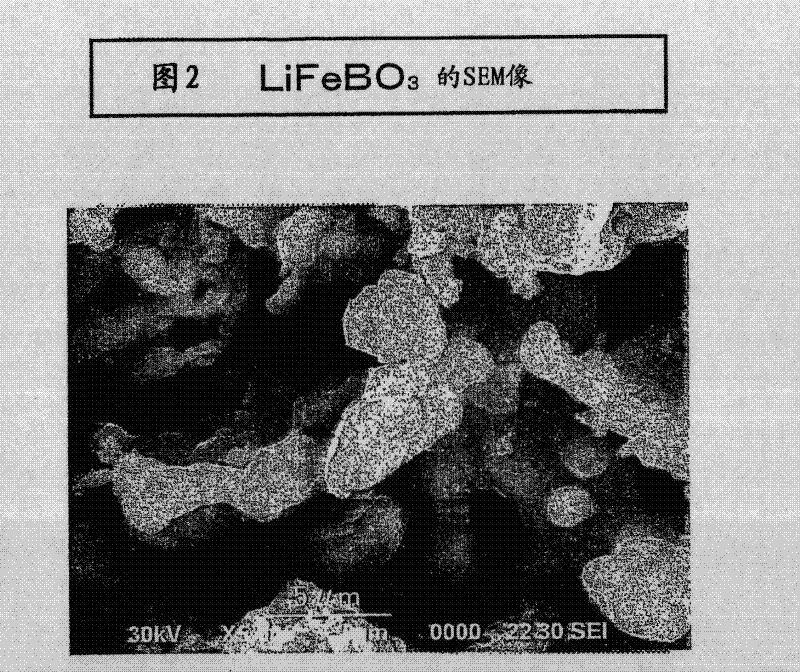

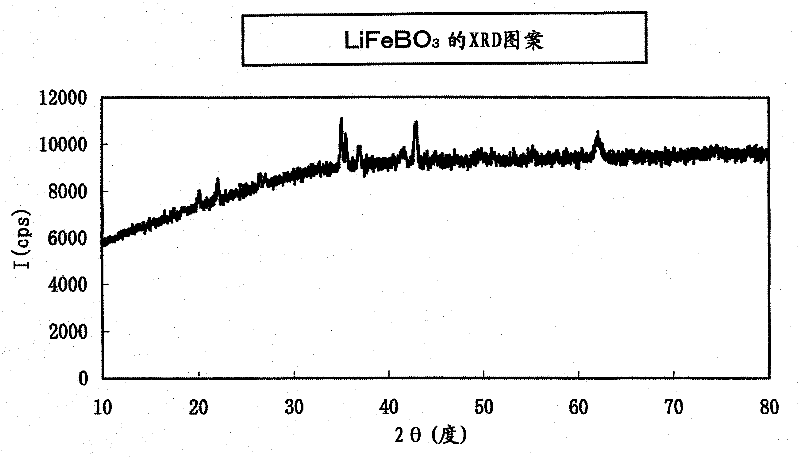

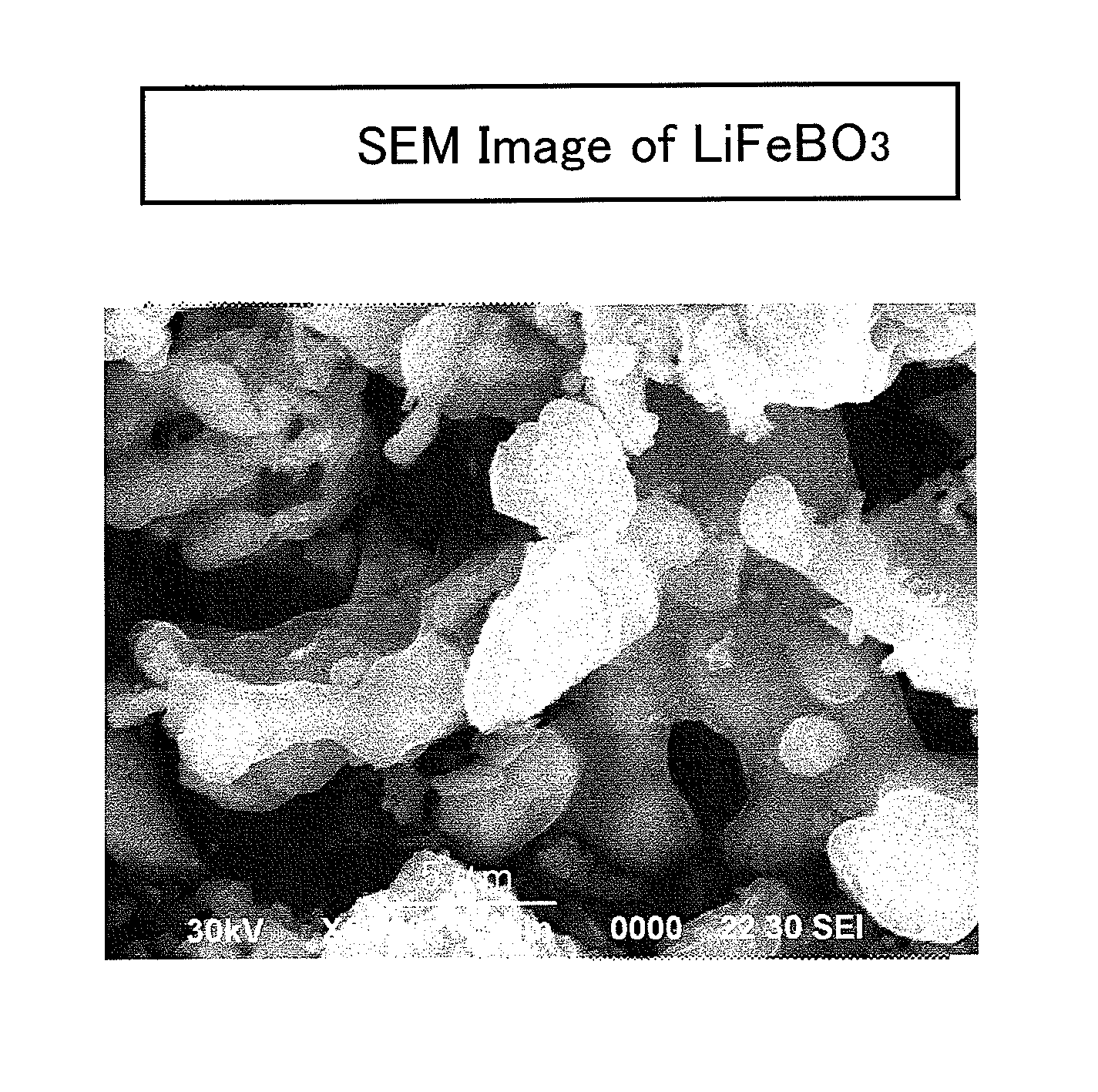

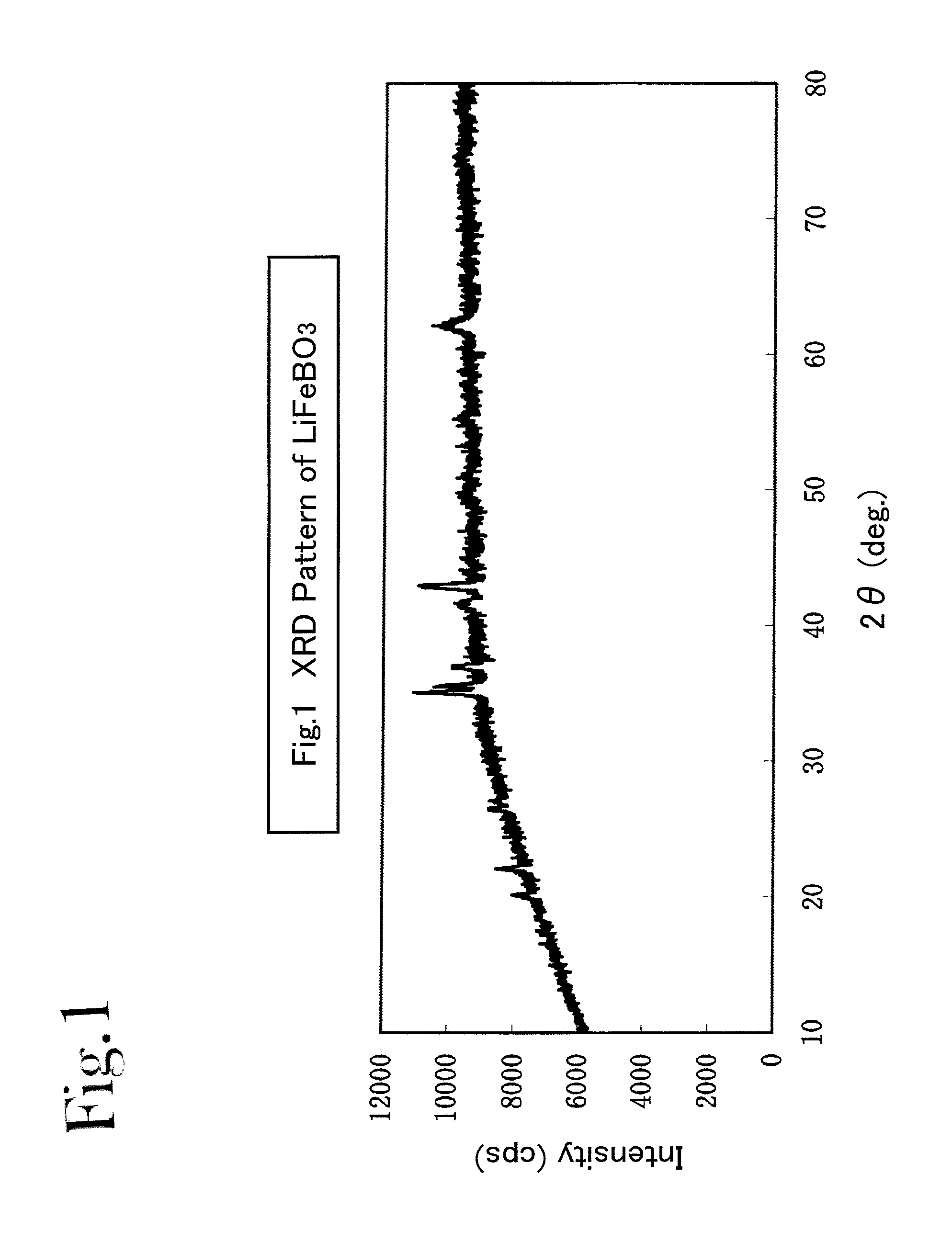

Process for producing lithium borate compound

InactiveCN102348640AReduce usageRich in resourcesMaterial nanotechnologyCell electrodesManganeseLithium compound

A process for producing, by a relatively simple means, a lithium borate material which is useful as a positive-electrode material for lithium-ion secondary batteries, etc. and has improved cycle characteristics, capacity, etc., and excellent performances. The process is characterized by reacting one or more divalent-metal compounds comprising at least one compound selected from a group consisting of compounds of divalent iron and compounds of divalent manganese with boric acid and lithium hydroxide in a reducing atmosphere at 400-650 DEG C in the melt of a carbonate mixture comprising lithium carbonate and at least one alkali metal carbonate selected from a group consisting of potassium carbonate, sodium carbonate, rubidium carbonate, and cesium carbonate.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

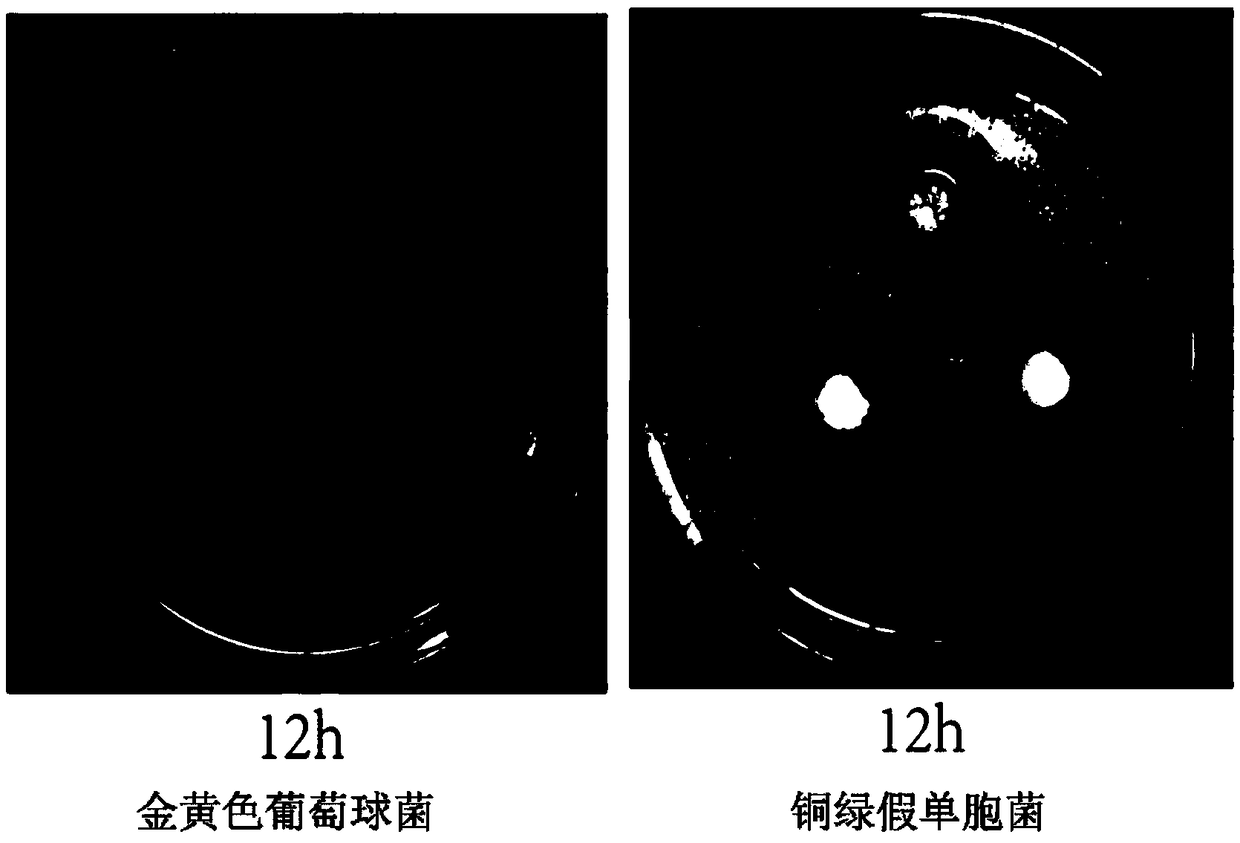

Method for preparing hydrogel surgical dressing and application of hydrogel surgical dressing

The invention discloses a method for preparing a hydrogel surgical dressing, and the method comprises the steps that alginic acid and rubidium carbonate are dissolved in water, magnetic stirring action is performed at set temperature, and after reaction, a rubidium alginate solution is obtained; the rubidium alginate solution is dissolved in water to obtain a sodium alginate solution, then the sodium alginate solution is mixed with the rubidium alginate solution, and an alginate solution is obtained; after calcium carbonate is uniformly dispersed into water, a dispersion solution is obtained,the dispersion solution is added to the alginate solution or the sodium alginate solution and stirred and mixed uniformly, and a pre-crosslinked solution is obtained; glucolactone is added to the pre-crosslinked solution, then cross-linking reaction is performed under the stirring condition, and the hydrogel surgical dressing is obtained after the reaction. According to the method for preparing the hydrogel surgical dressing and application of the hydrogel surgical dressing, the functions of oxidation resistance, cell metabolism promotion and bacteria growth inhibition of the rubidium ions areused, the rubidium ions are introduced into hydrogel, the antibacterial property of the hydrogel is enhanced, the cell growth can be accelerated, and wound surface healing is promoted.

Owner:CENT SOUTH UNIV

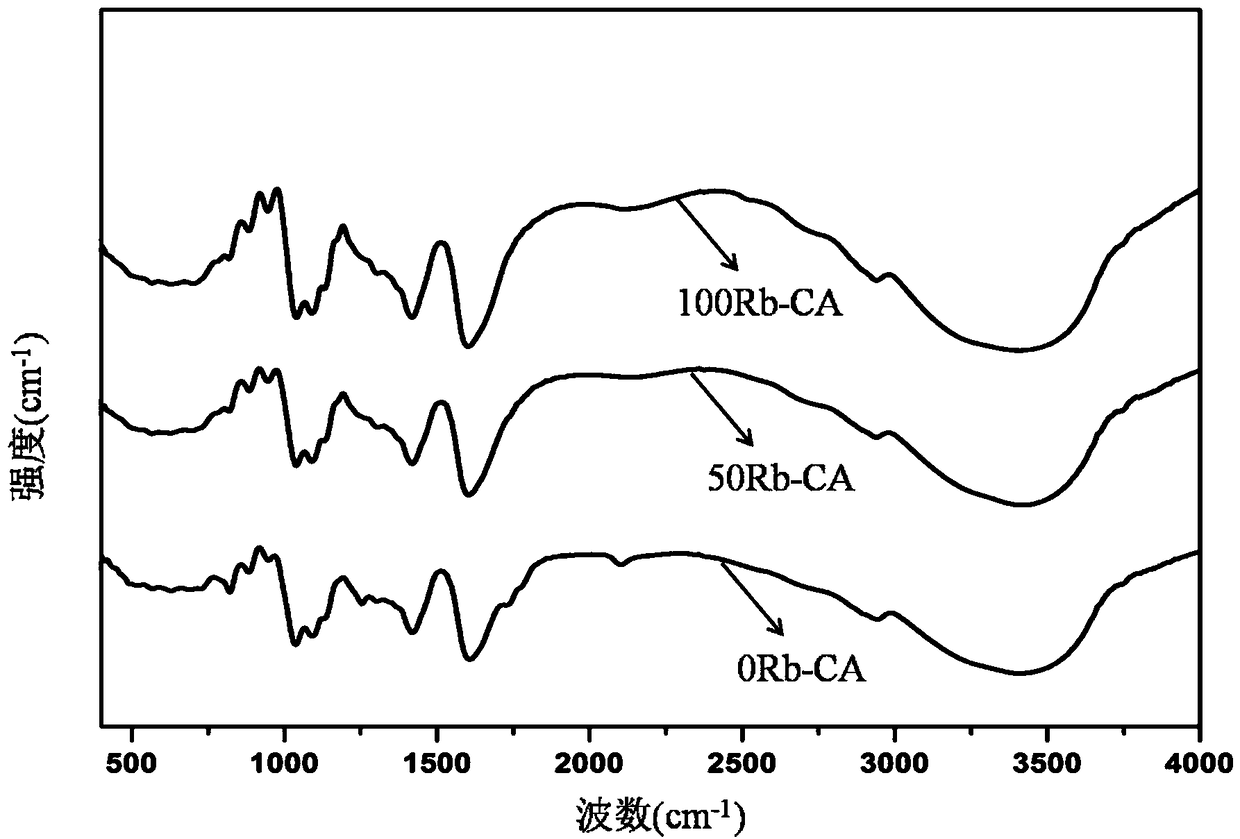

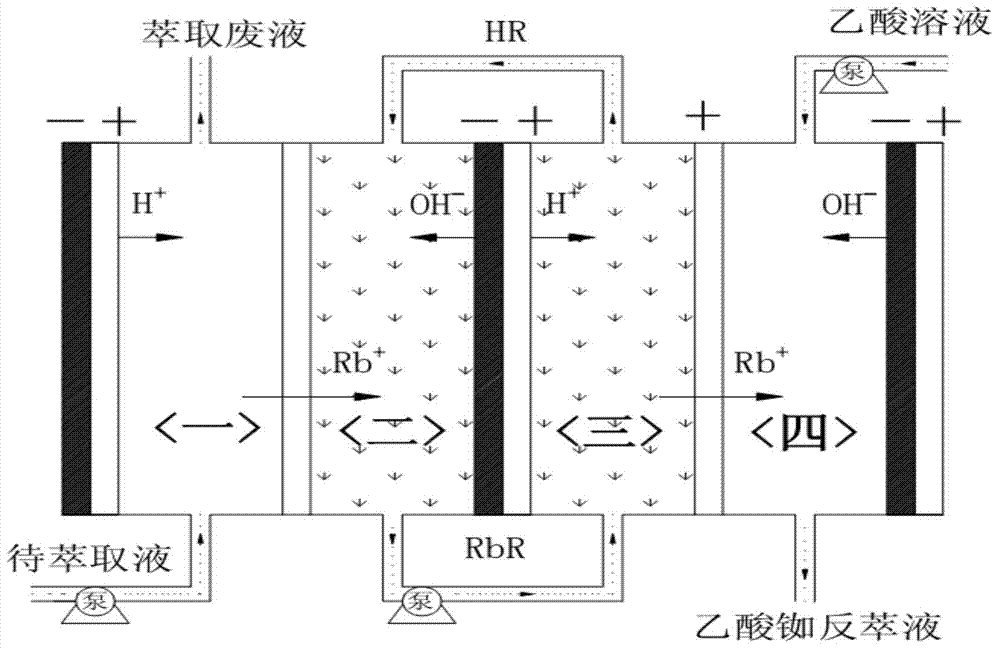

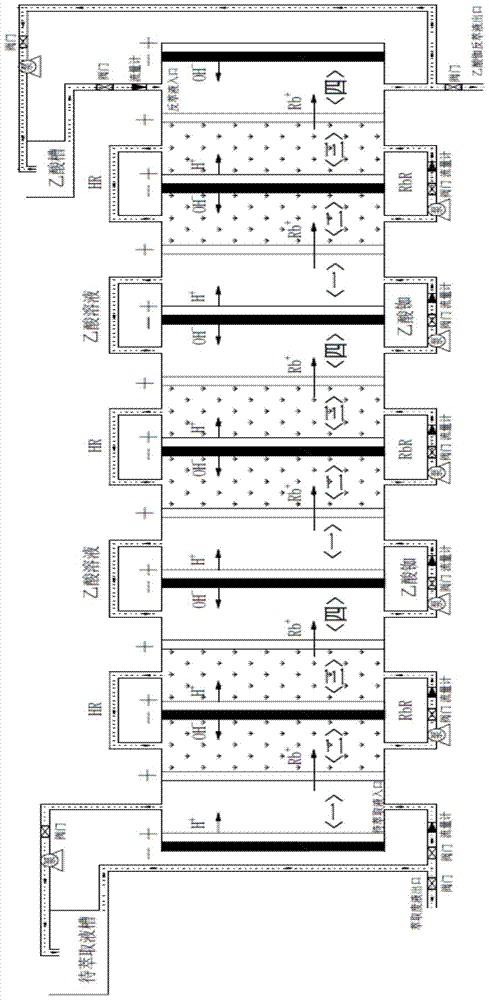

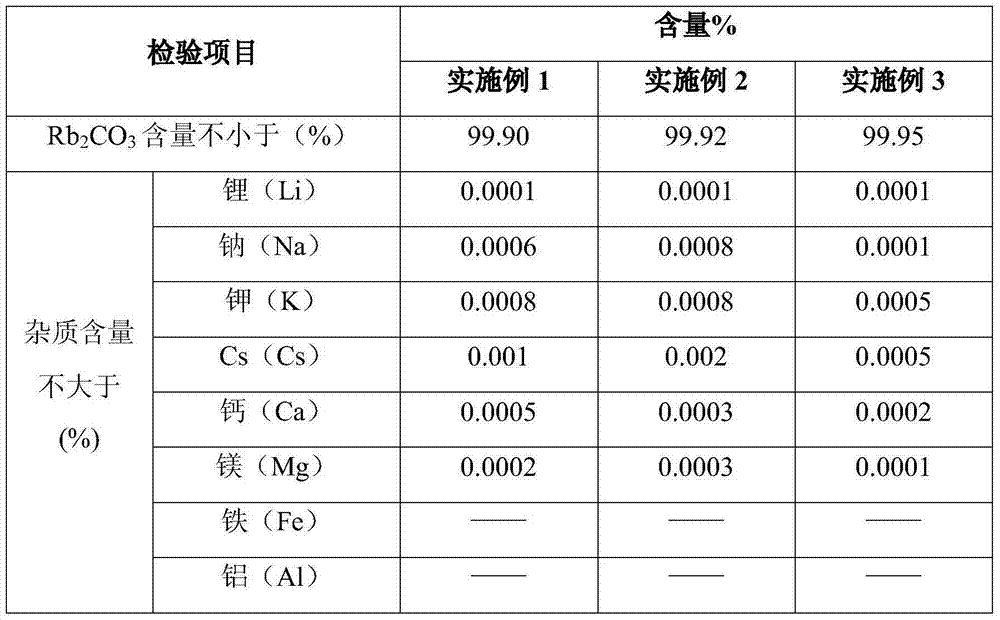

Method for preparing high-purity rubidium carbonate

The invention belongs to the technical field of methods for extracting metal ions by the aid of bipolar membrane electric osmosis technology and further generating a high-purity inorganic metal compound, and particularly relates to a method for preparing high-purity rubidium carbonate by the aid of the bipolar membrane electric osmosis technology by taking rubidium-containing waste liquor as a raw material. The method includes the steps: firstly, concentrating the rubidium-containing waste liquor, removing magnesium, iron, aluminum, calcium and barium; secondly, further removing calcium to obtain liquor to be extracted; thirdly, extracting rubidium from the liquor to be extracted by the aid of an electric extraction device to prepare rubidium acetate strip liquor; finally, concentrating, crystallizing and decomposing the rubidium acetate strip liquor at high temperature to obtain the rubidium carbonate. The method is efficient and environmentally friendly, and the obtained rubidium carbonate is excellent in quality and suitable for industrial popularization and application.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

Production process for lithium-borate-system compound

InactiveUS20110315919A1Low environmental loadKeep down eliminationMaterial nanotechnologyElectrode manufacturing processesLithium hydroxideManganese

A process is provided, process which makes it possible to produce lithium-borate-system materials by means of relatively simple means, lithium-borate-system materials which are useful as positive-electrode active materials for lithium-ion secondary battery, and the like, whose cyclic characteristics, capacities, and so forth, are improved, and which have better performance. The present production is characterized in that a divalent metallic compound including at least one member of compounds that is selected from the group consisting of divalent-iron compounds and divalent-manganese compounds, and boric acid as well as lithium hydroxide are reacted at 400-650° C. in a molten salt of a carbonate mixture comprising lithium carbonate and at least one member of alkali-metal carbonates that is selected from the group consisting of potassium carbonate, sodium carbonate, rubidium carbonate and cesium carbonate in a reducing atmosphere.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

High-performance glass micro-bead for reflective film and preparation method thereof

InactiveCN104961344AHigh refractive indexImprove performancePotassium hexafluorophosphateBarium titanate

The invention discloses a high-performance glass micro-bead for a reflective film and a preparation method thereof. The high-performance glass micro-bead for the reflective film is prepared by using the following raw materials in parts by weight: 33 to 45 parts of bryozoatum, 21 to 32 parts of silicon-calcium slag, 24 to 39 parts of topaz, 14 to 23 parts of rubidium carbonate, 18 to 29 parts of kaolin, 25 to 35 parts of barite, 10 to 15 parts of borax, 5 to 10 parts of calcium sulfate, 6 to 12 parts of sodium nitrate, 5 to 10 parts of barium titanate, 4 to 8 parts of potassium hexafluorophosphate and 8 to 12 parts of additive. By using industrial waste silicon-calcium slag as a main raw material and using silicon-calcium slag with components such as bryozoatum, barite, topaz, rubidium carbonate, barium titanate and potassium hexafluorophosphate in a combined manner, not only can the waste be utilized as resources, but also the comprehensive performance of the glass micro-bead is improved, the high-performance glass micro-bead disclosed by the invention has the advantages of high refractive index, high strength, good chemical stability, aging resistance, high temperature resistance, corrosion resistance and the like, and the economic benefit is good.

Owner:HEFEI DINGLIANG OPTICAL TECH

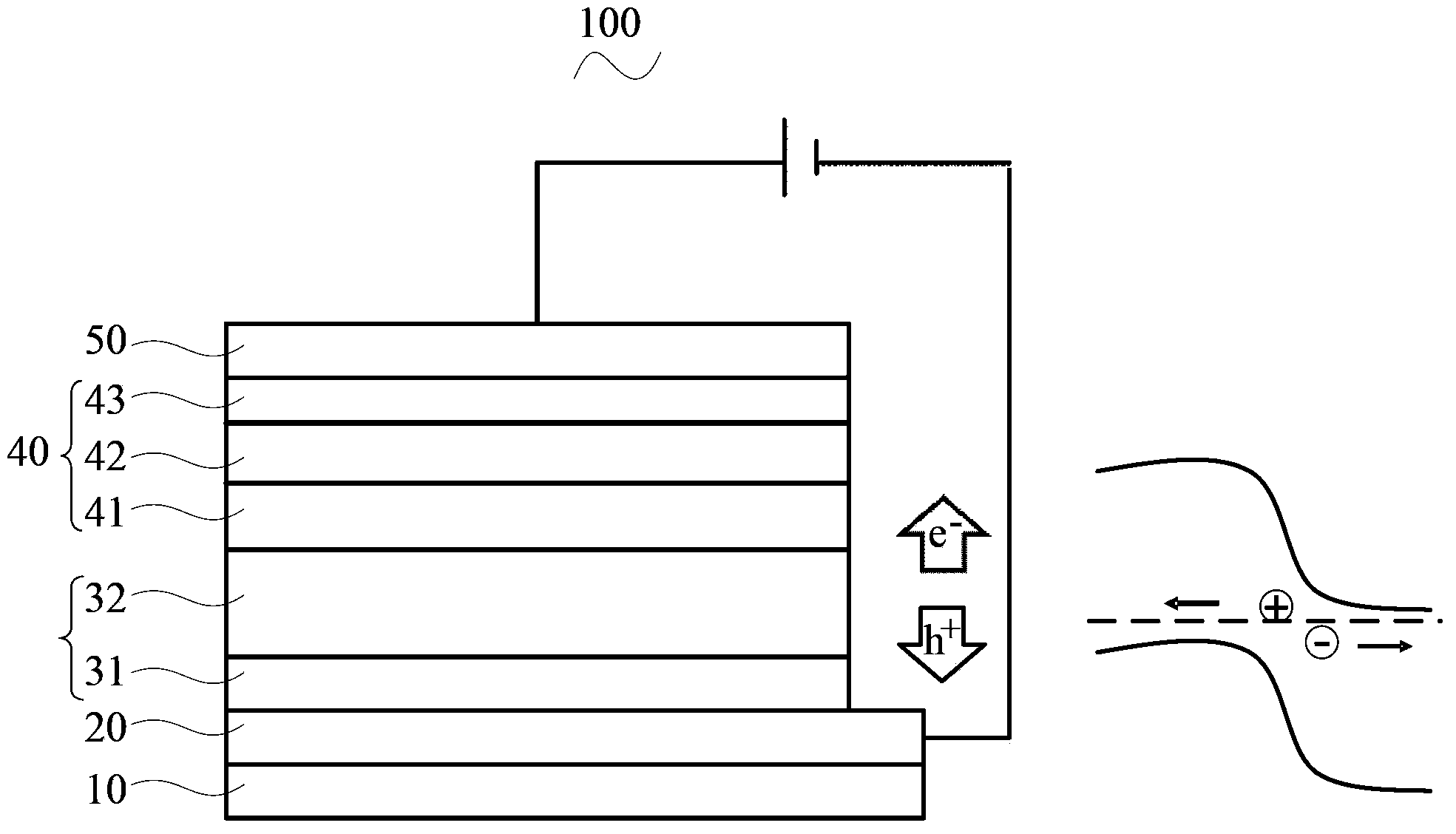

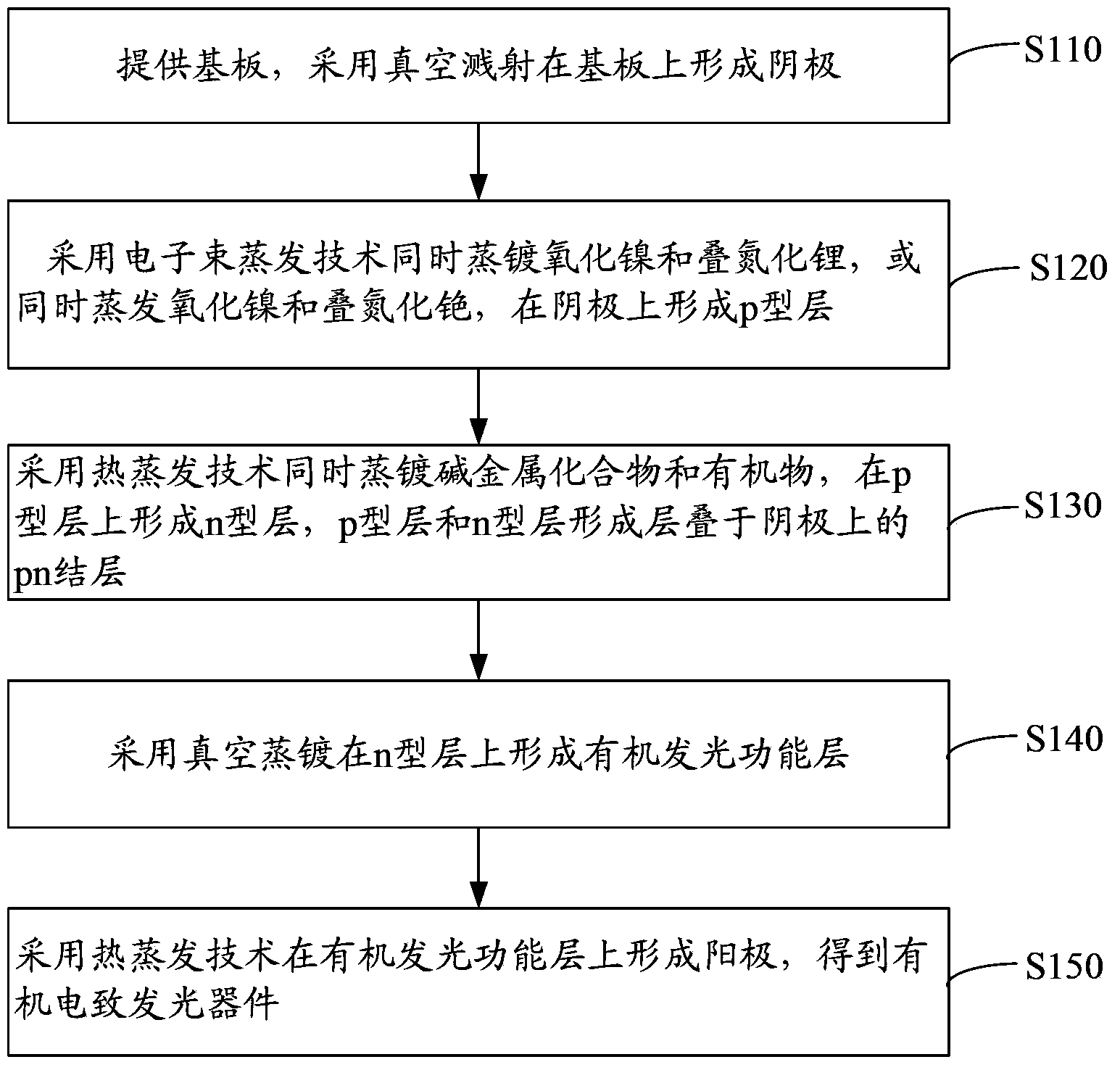

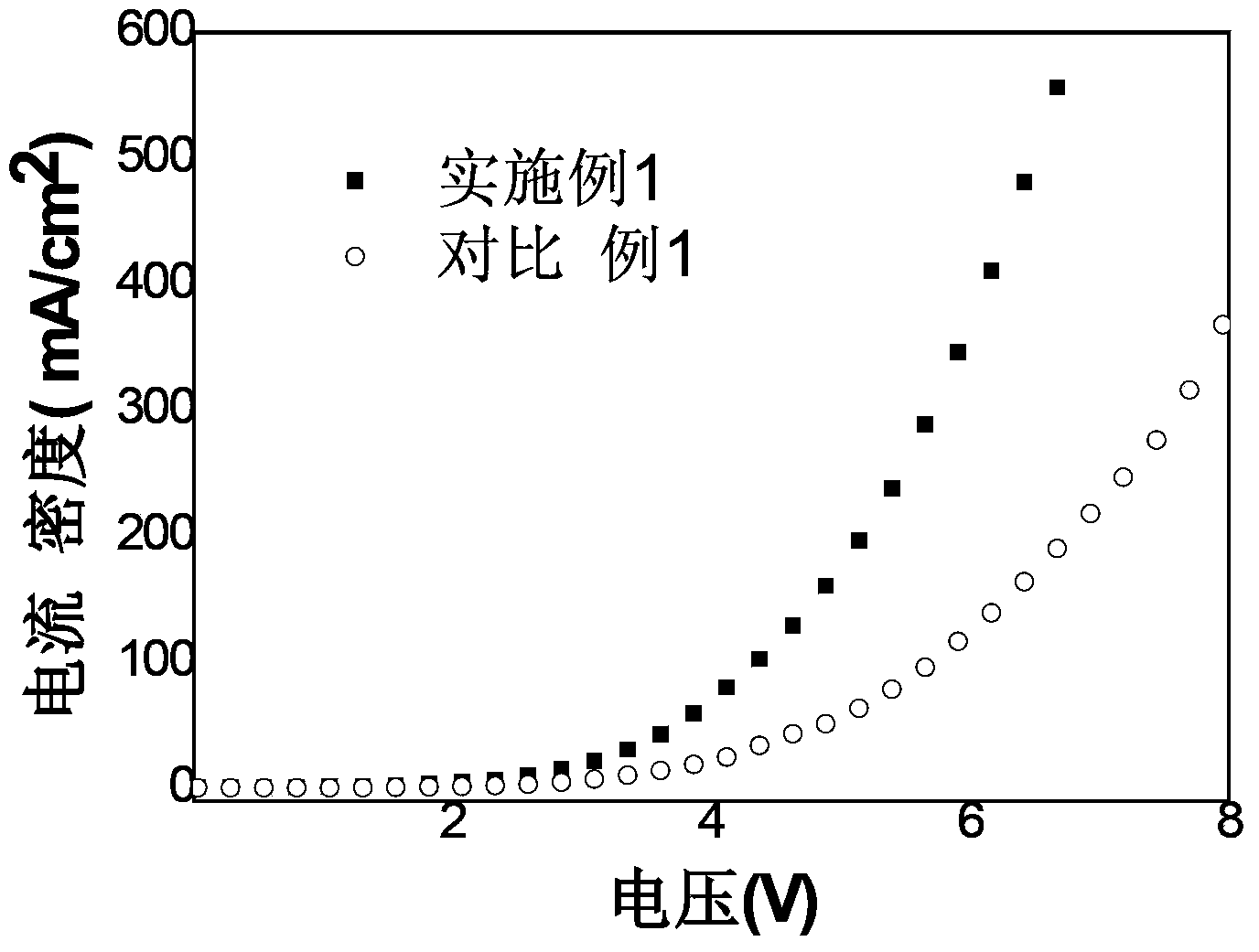

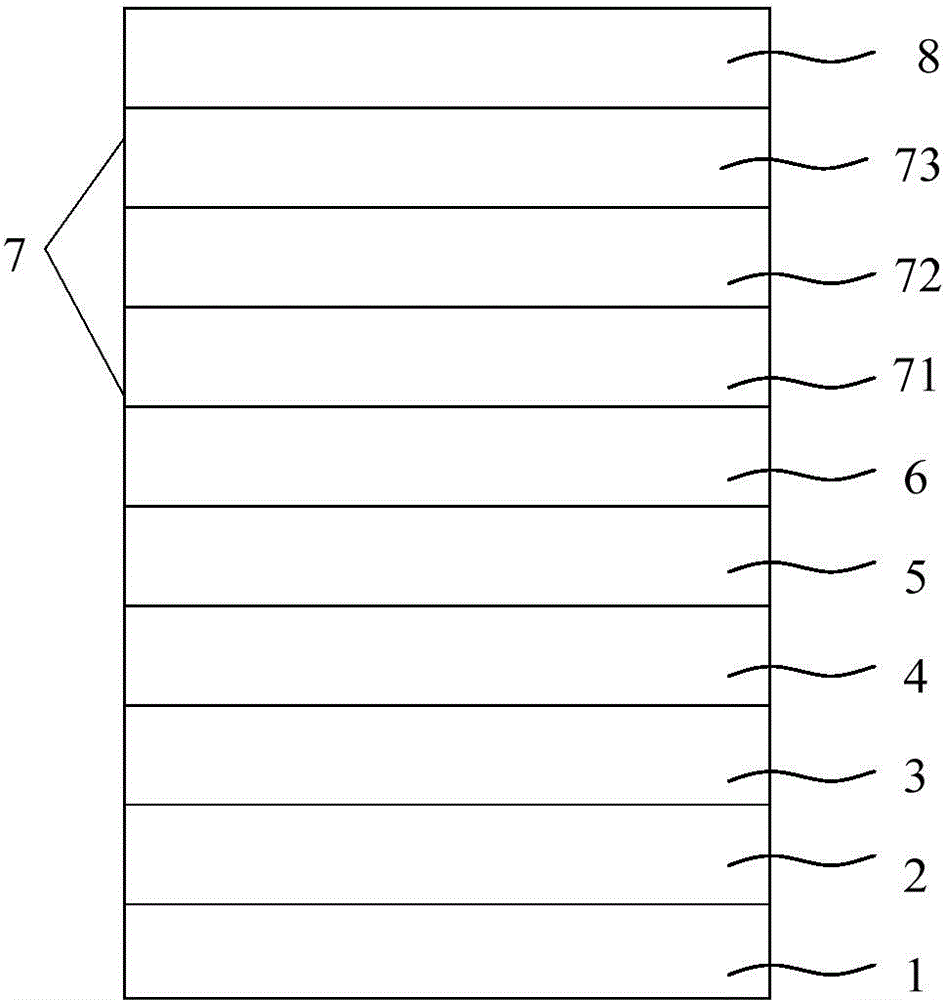

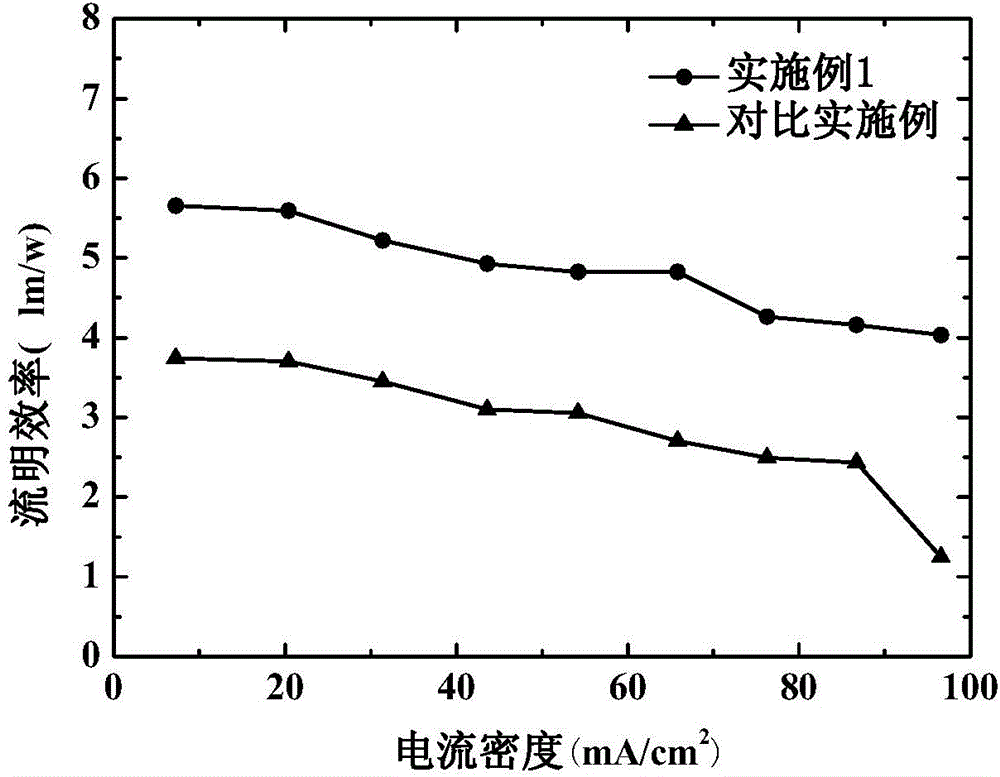

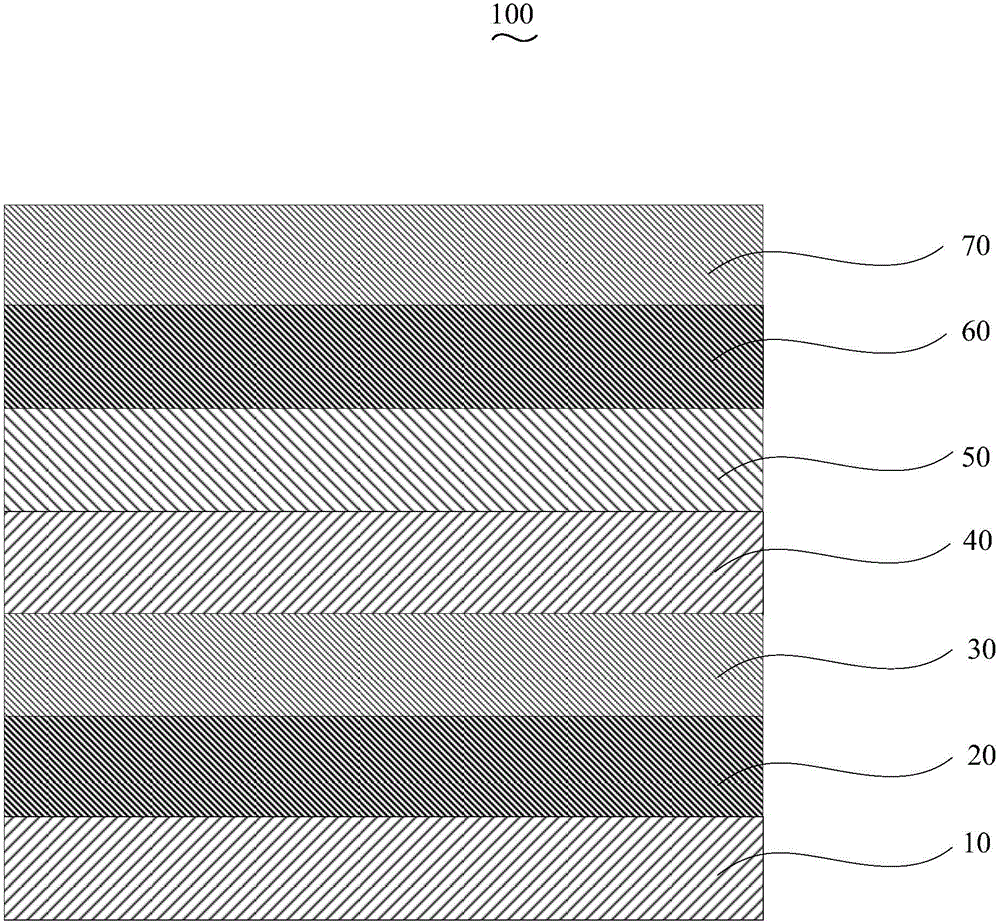

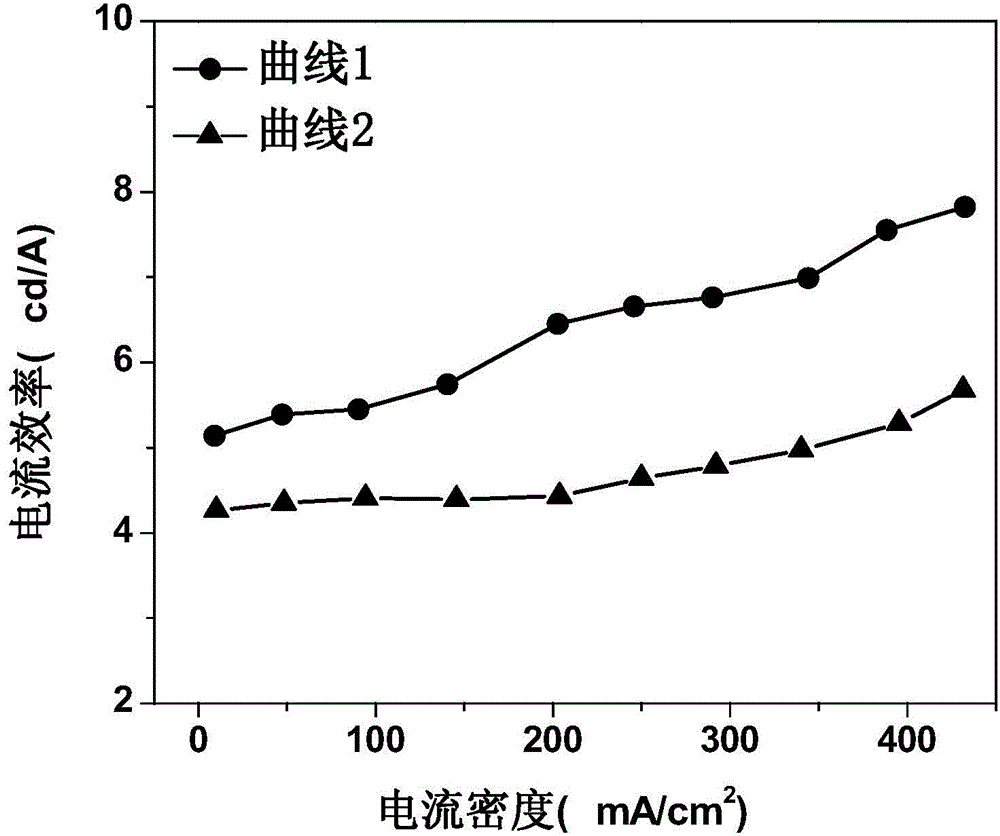

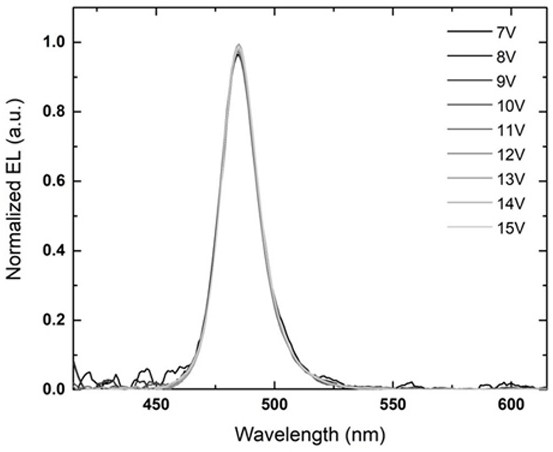

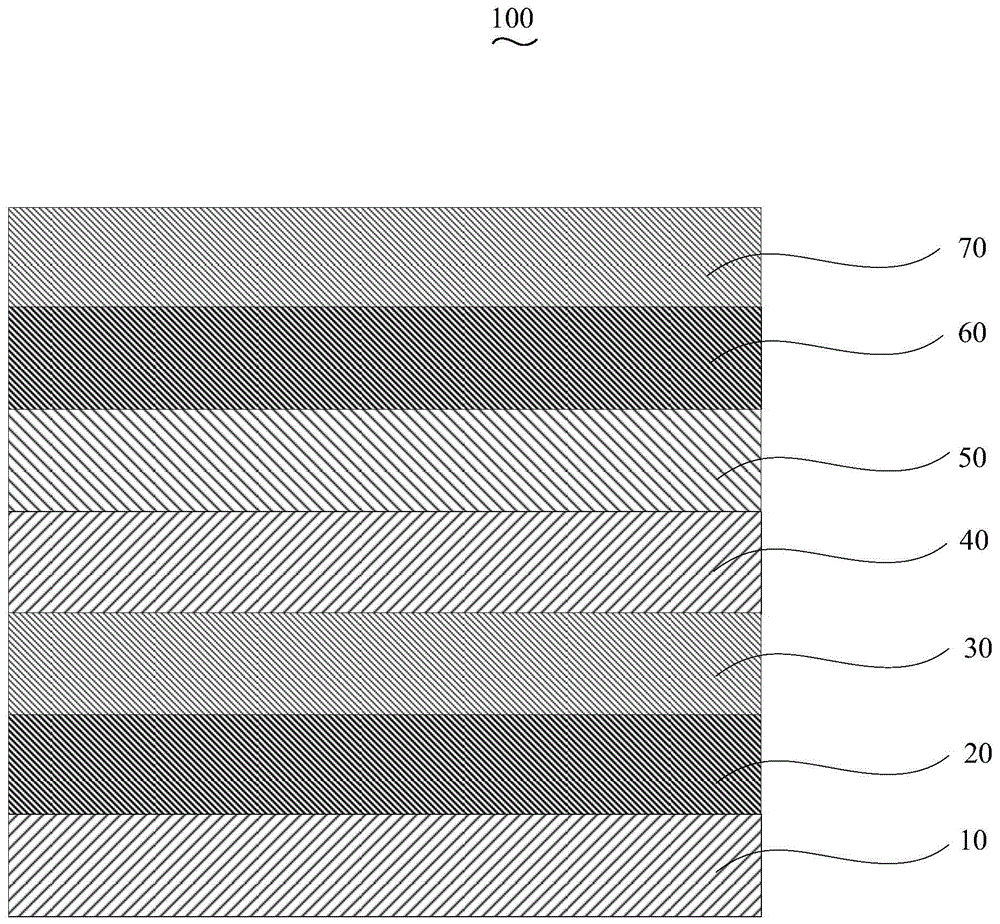

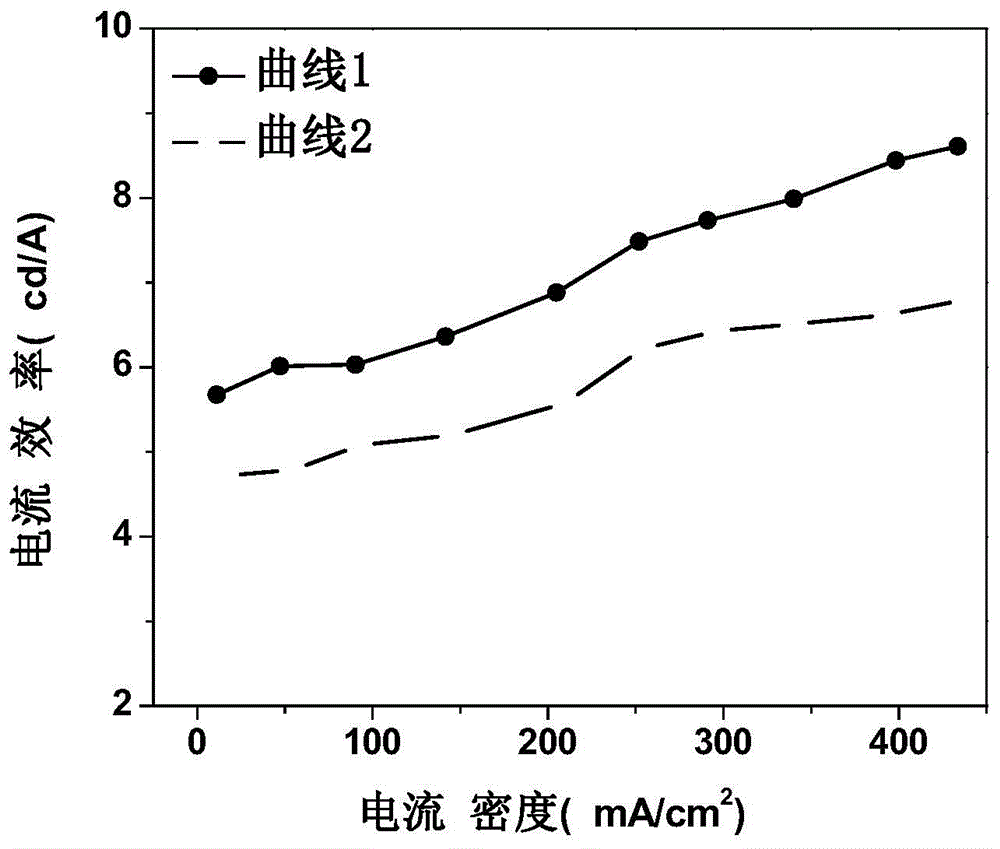

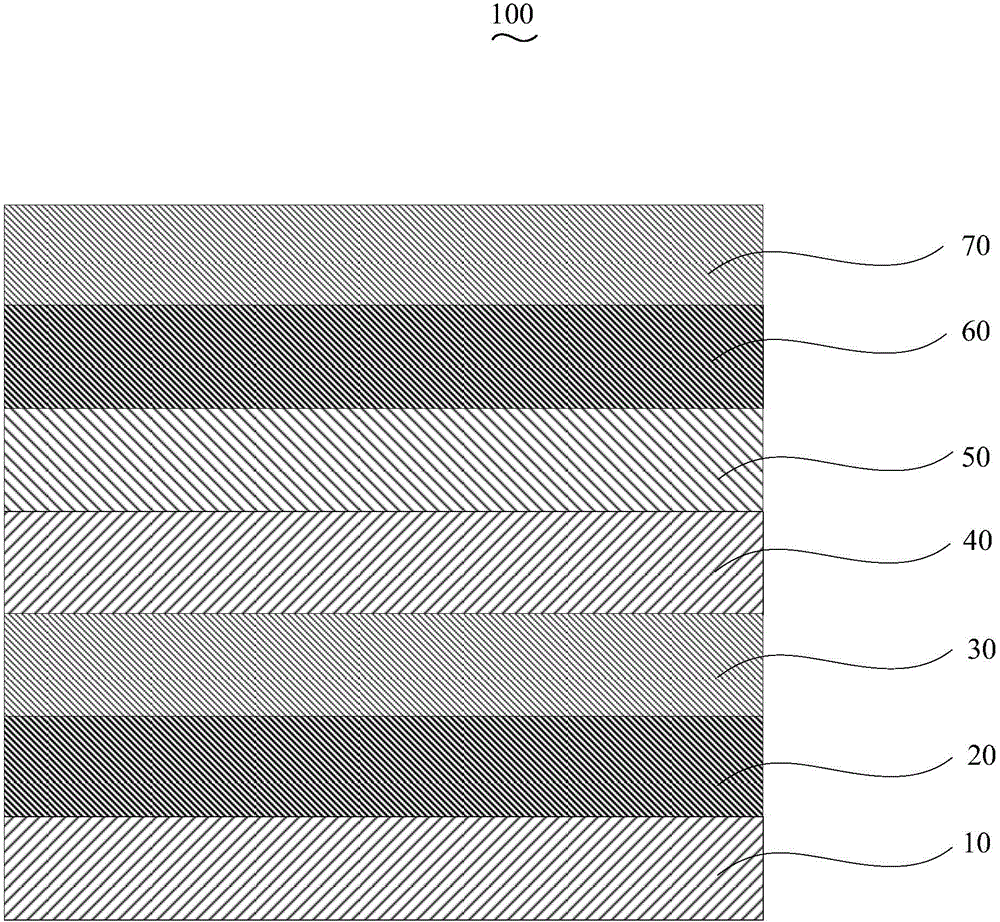

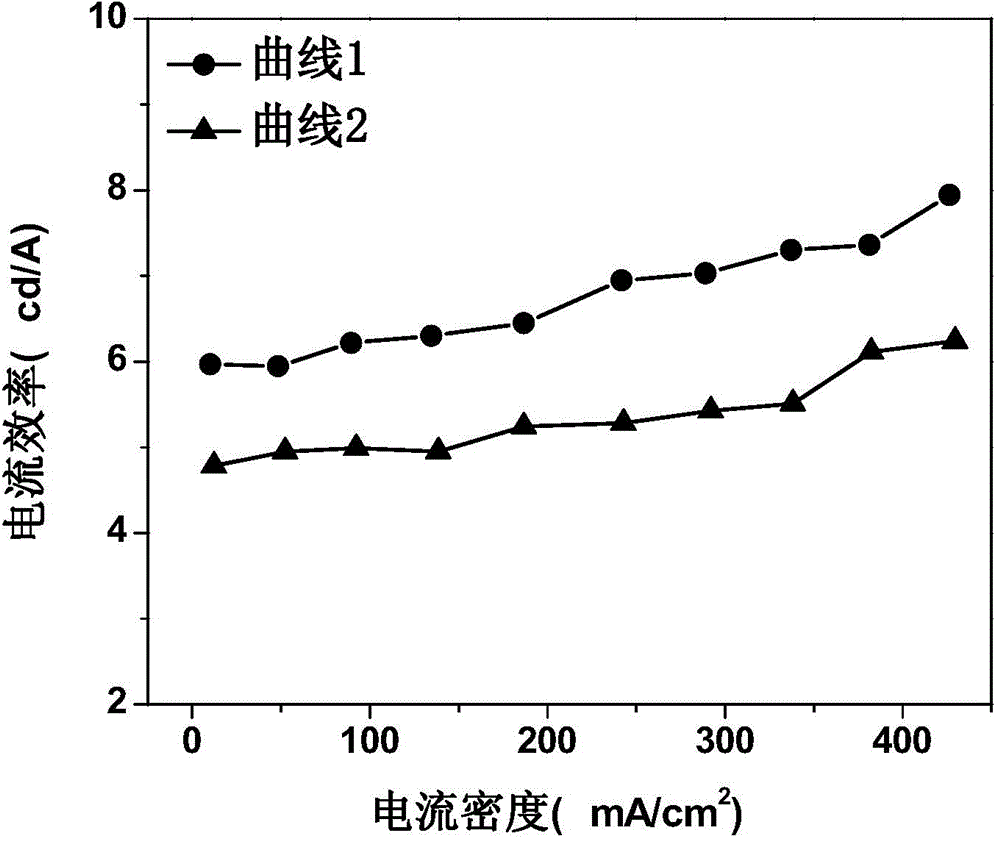

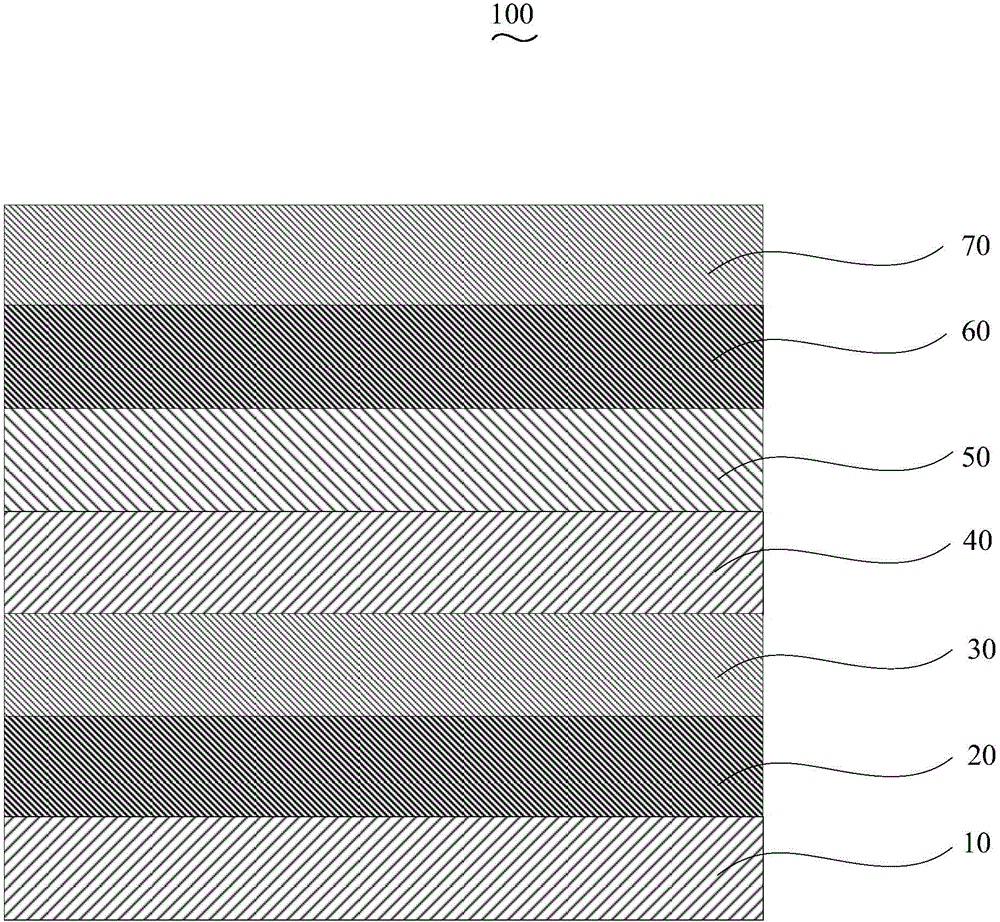

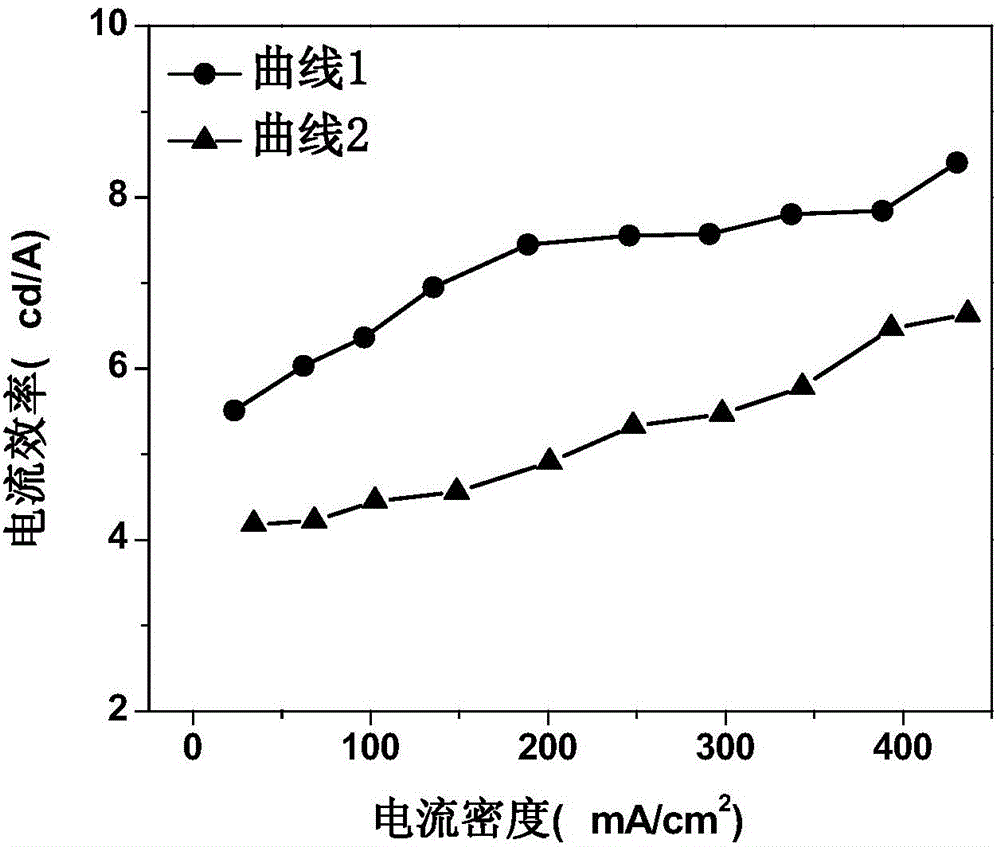

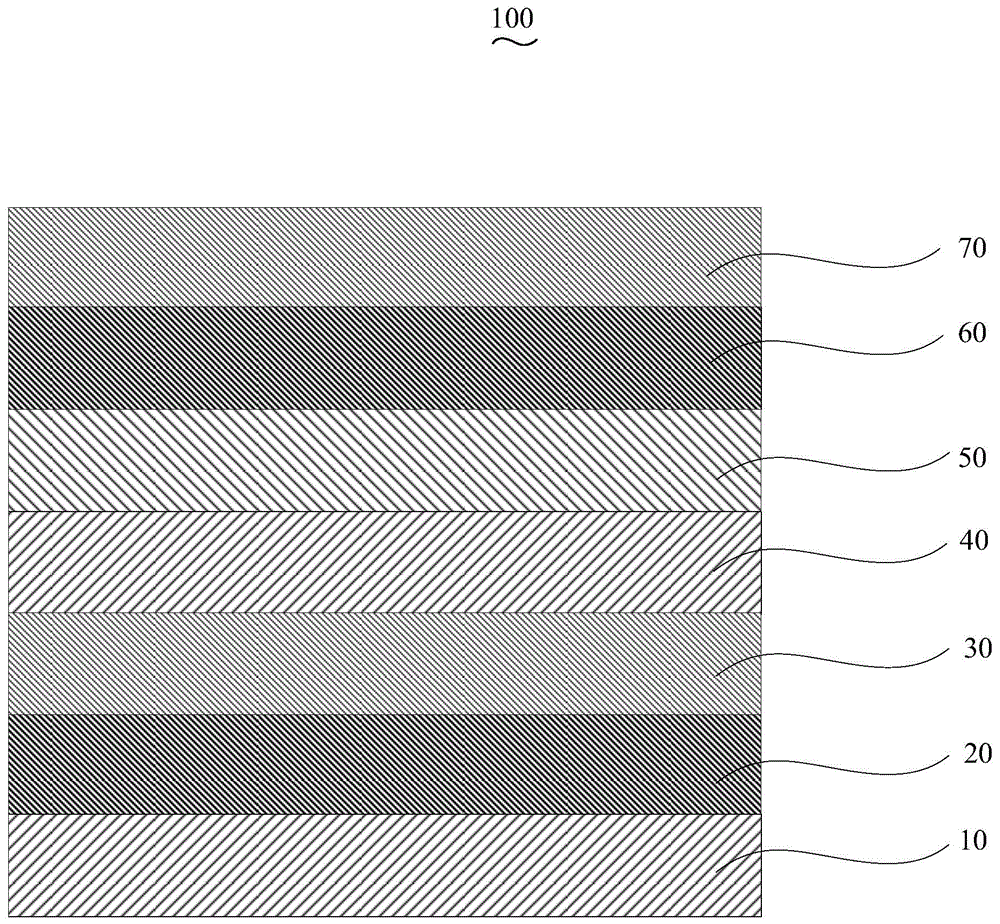

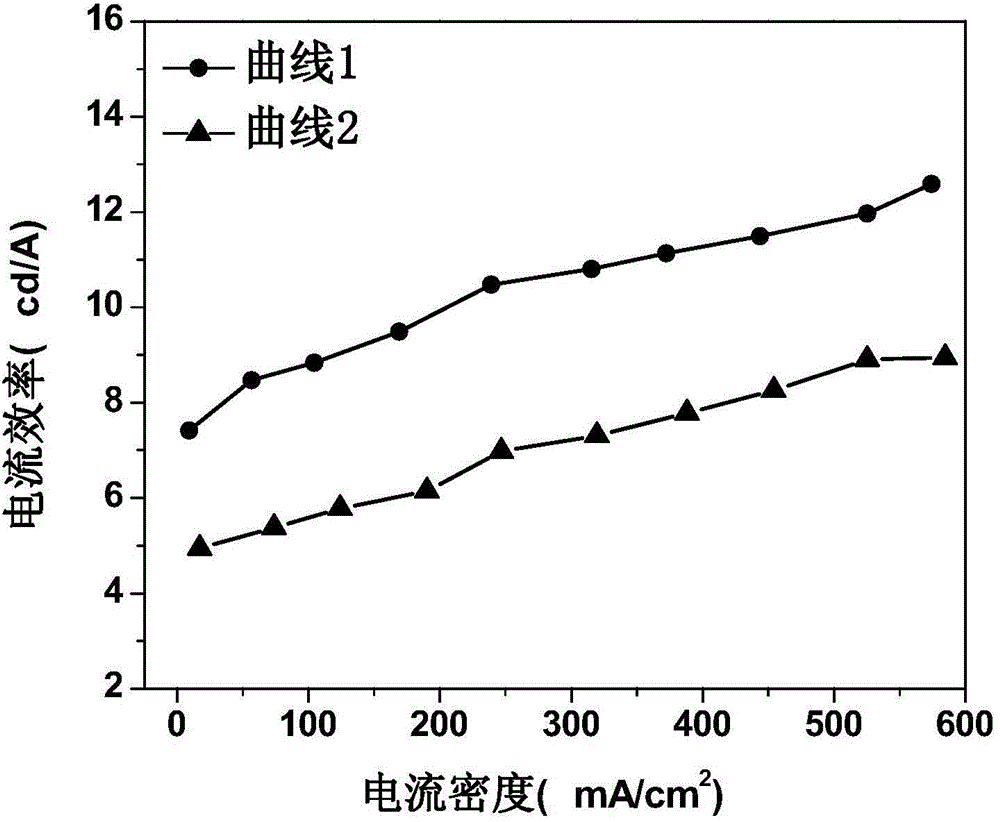

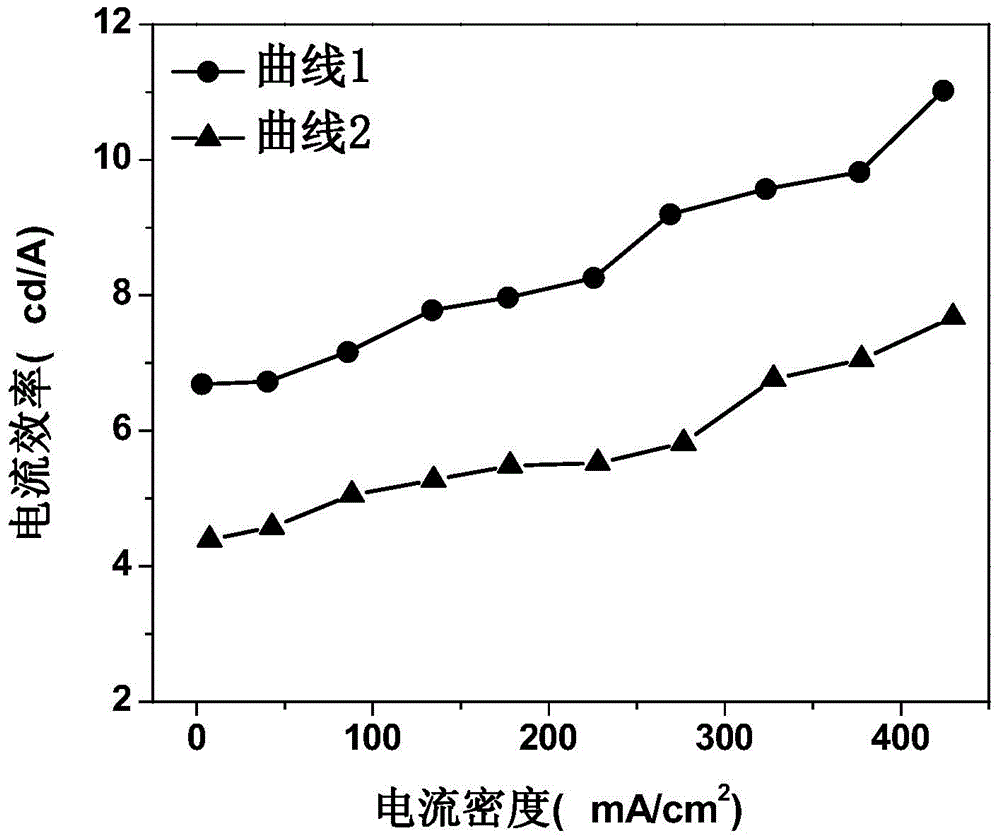

Inversion-type organic light-emitting device and preparation method thereof

InactiveCN104051653ASolve the problem of difficult injectionImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingTriazole derivatives8-Hydroxyquinoline

The invention relates to an inversion-type organic light-emitting device and a preparation method thereof. The inversion-type organic light-emitting device includes a substrate, a cathode, an organic light-emitting function layer, and an anode, which are sequentially laminated, and a pn junction layer arranged between the cathode and the organic light-emitting function layer. The pn junction layer includes a p-type layer and an n-type layer, which are sequentially laminated on the cathode. The p-type layer is formed by doping lithium or caesium into nickel oxide. The n-type layer is formed by doping an alkali metal compound into an organic matter. The alkali metal compound is lithium carbonate, cesium azide, lithium borohydride, lithium fluoride or rubidium carbonate. The organic matter is (8-hydroxyquinoline)-aluminum, 4,7-diphenyl-o-phenanthroline, 1,3,5-tris(1-phenyl-1H-benzimidazole-2-base) benzene, 2,9-dimethyl-4,7-diphenyl-1, 10-orthophenanthroline or 1,2,4-triazole derivative. The inversion-type organic light-emitting device solves a problem that current carrier injection is difficult and is comparatively high in light-emitting efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

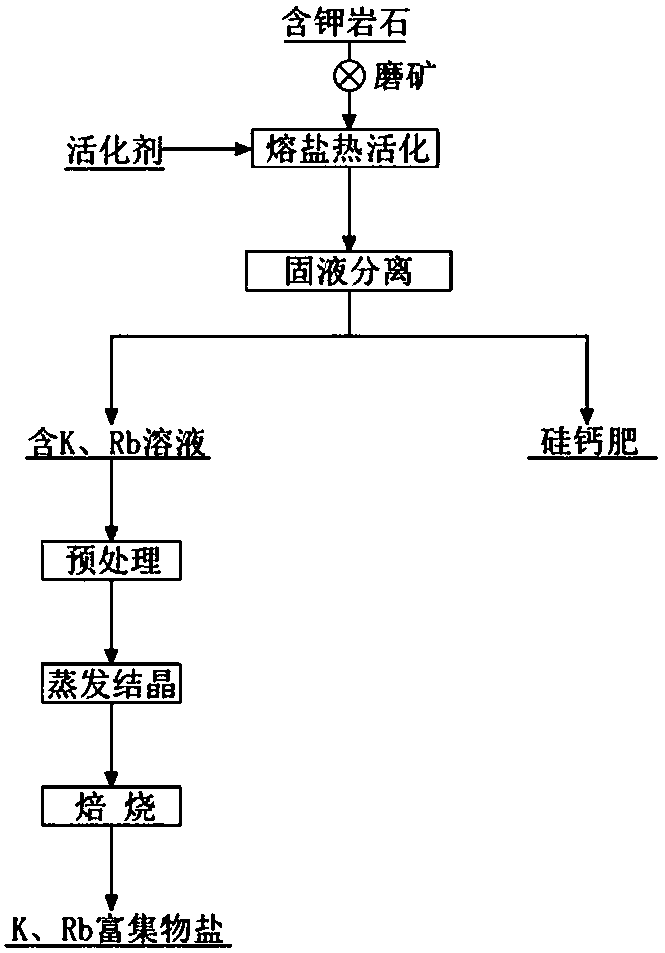

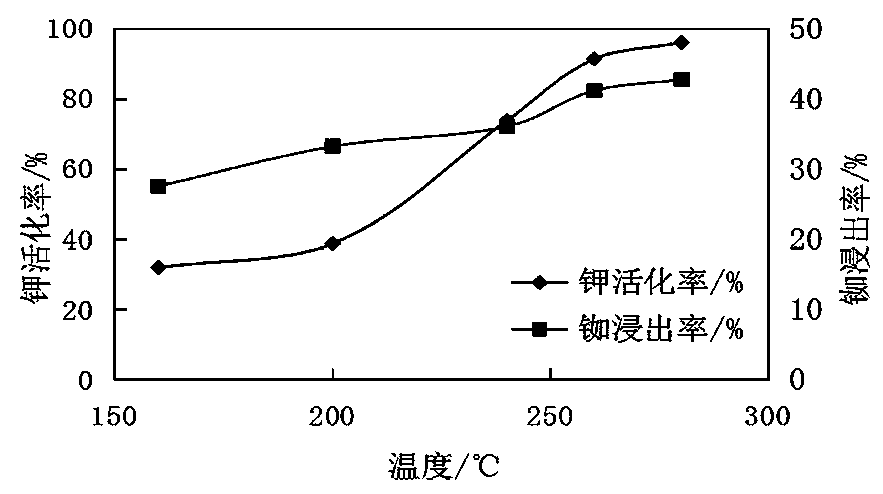

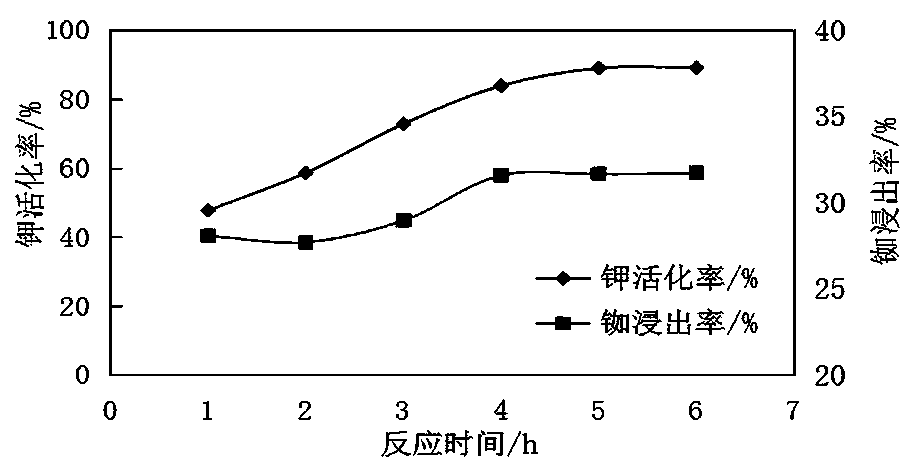

Method for cooperatively extracting potassium and rubidium from potassium-containing rock

ActiveCN111534704AEasy to purifyReduce energy consumptionProcess efficiency improvementRubidium carbonatePotassium

The invention relates to the field of mineral processing and wet metallurgy, in particular to a method for cooperatively extracting potassium and rubidium from potassium-containing rock. The method comprises the following steps: crushing and grinding potassium-containing rock to obtain mineral powder; mixing the potassium-containing rock with the alkaline additive quick lime or slaked lime, addingwater to obtain a mixture, and placing the mixture in a molten salt furnace to activate the mixture through heat of fused salt; carrying out solid-liquid separation on the activated mixture to obtainfiltering liquid and filtering residue containing potassium and rubidium, wherein the filtering residue is used for producing silicon and calcium fertilizer; adding potassium carbonate aqueous solution in the filtering liquid for carbonization, and filtering to remove impurities to obtain secondary filtering liquid; carrying out evaporative crystallization on the secondary filtering liquid to obtain potassium and rubidium crystal substances; and roasting the potassium and rubidium crystal substances to contain potassium and rubidium containing enriched product, and carrying out purification and separation to obtain potassium carbonate and rubidium carbonate. Lime is adopted as the alkaline additive, the solid-liquid separation filtering liquid is alkaline, calcium ions precipitate to enter tailings, and the tailings are used for preparing silicon and calcium fertilizer. Compared with adoption of sodium hydroxide as the alkaline additive, the cost is lower, and the potassium and sodiumseparation process is eliminated in filtering liquid to facilitate purification of potassium and rubidium.

Owner:山西省岩矿测试应用研究所

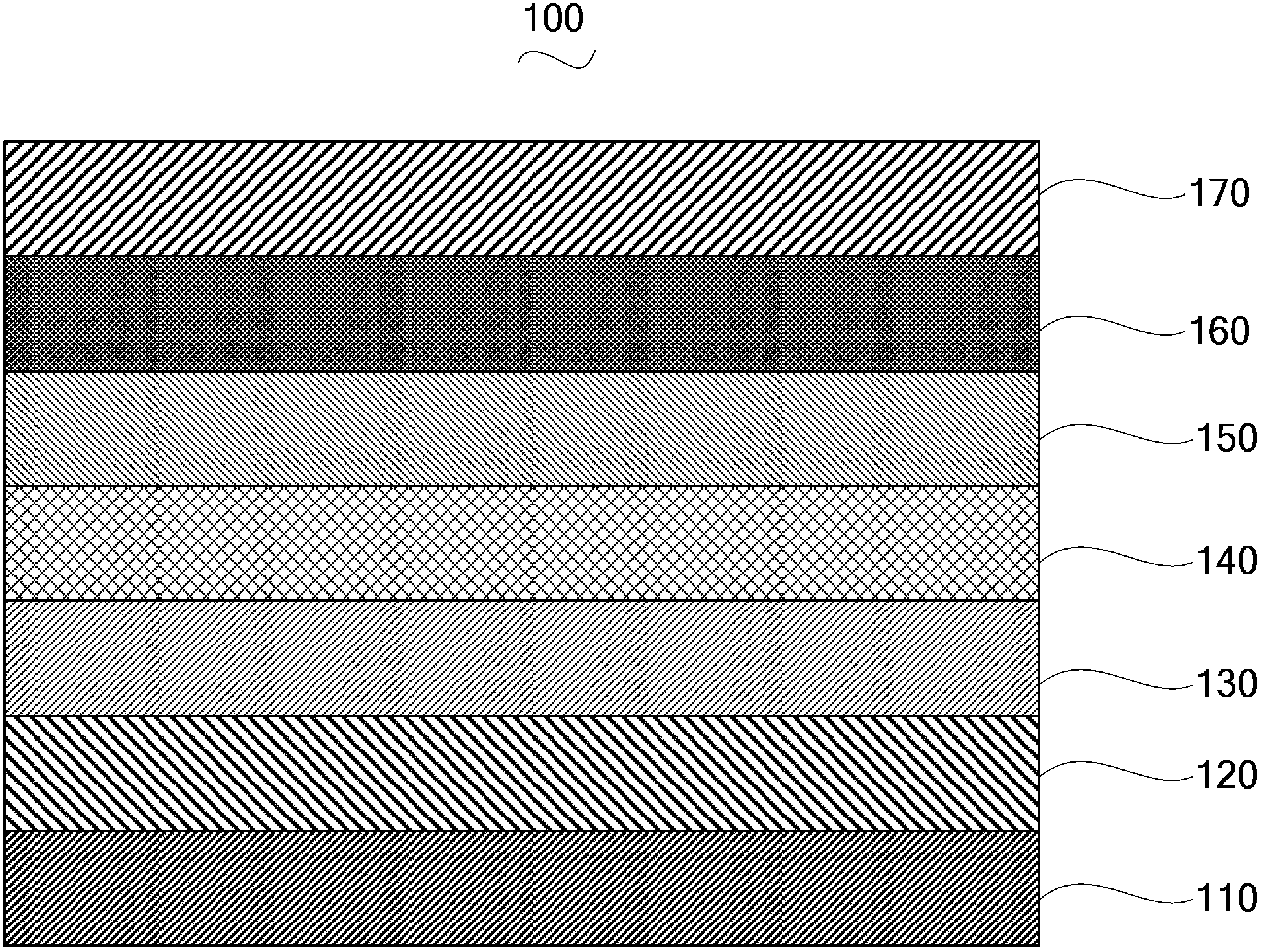

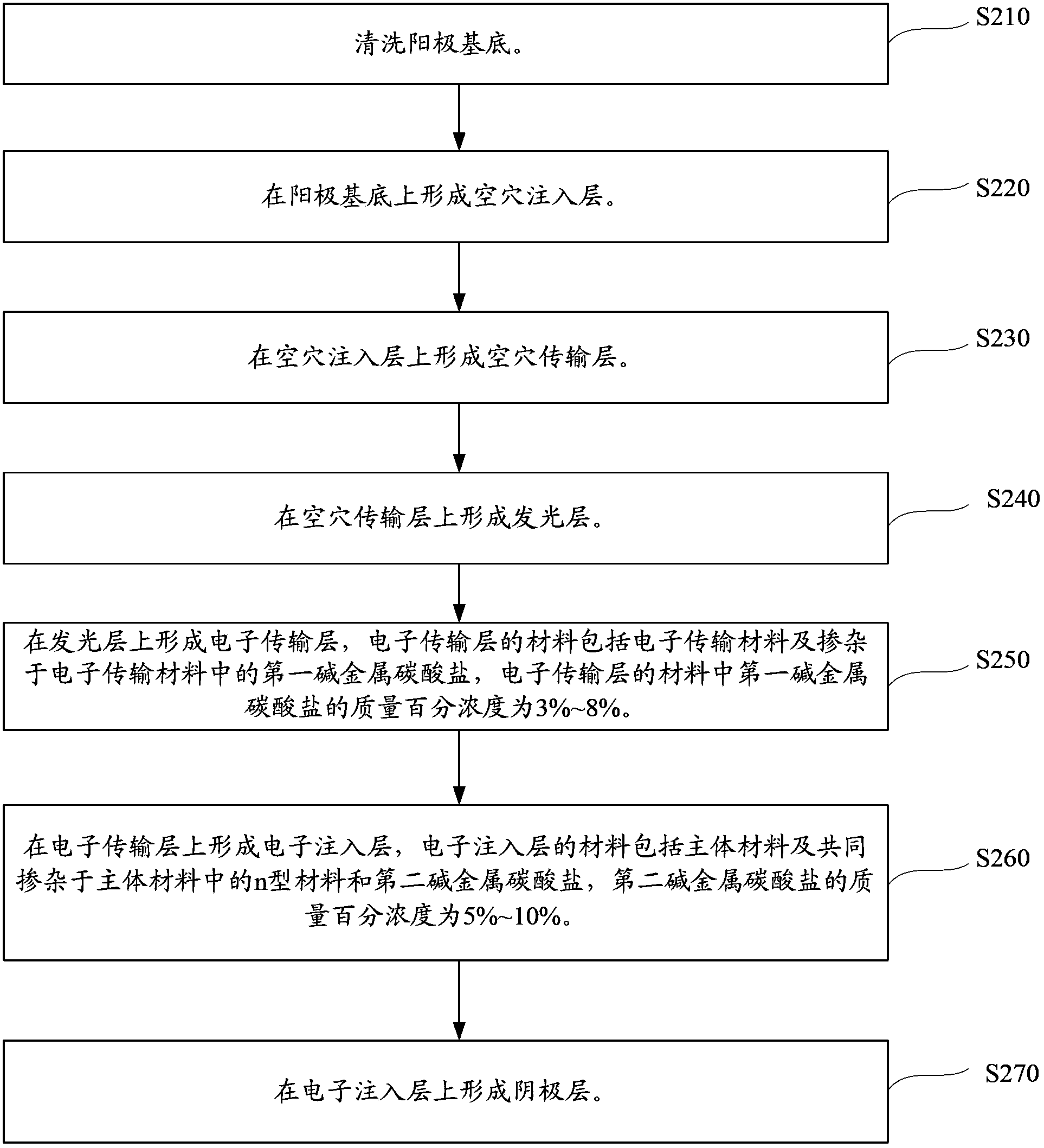

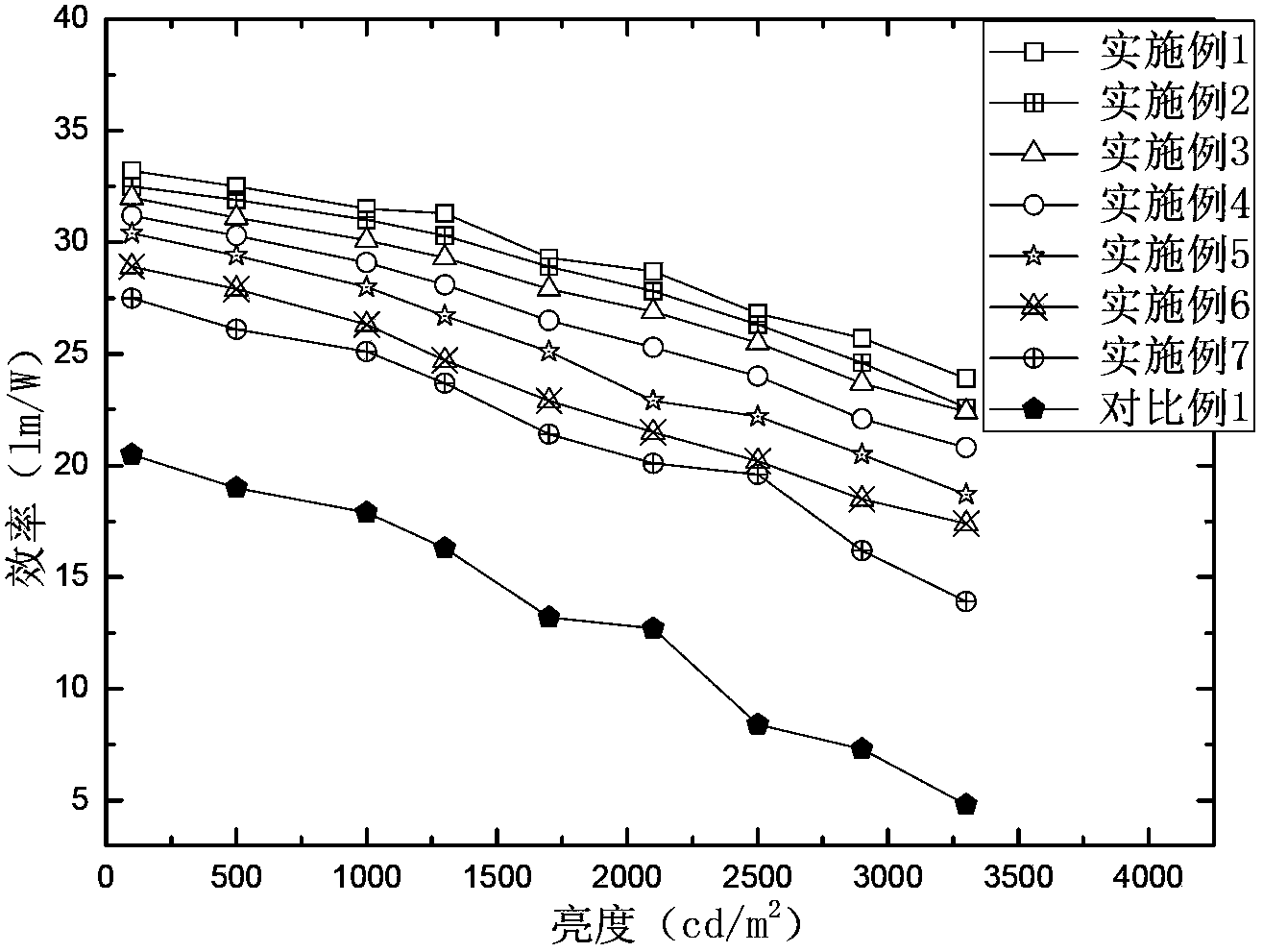

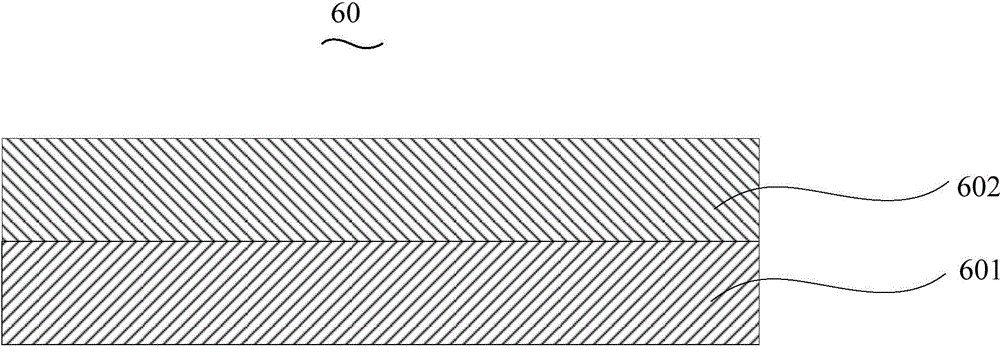

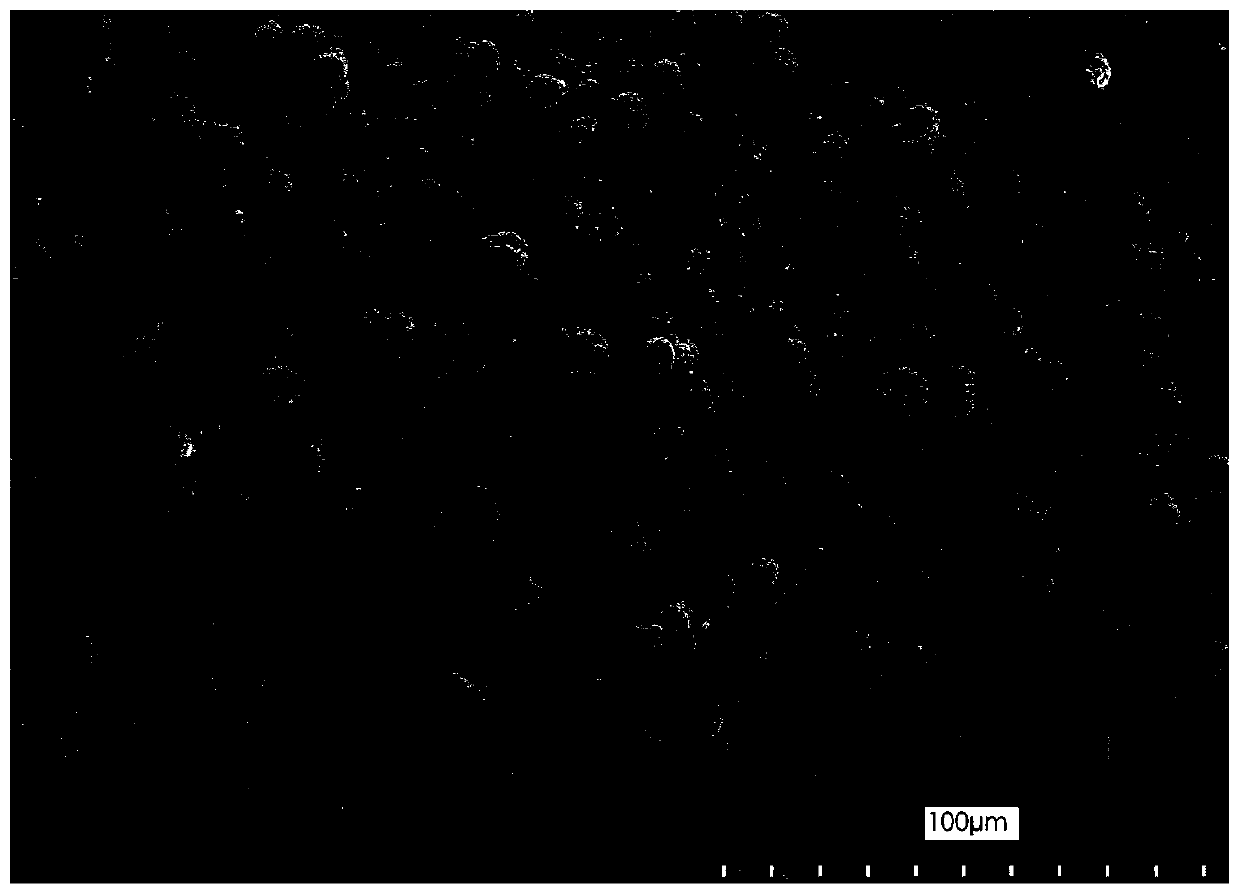

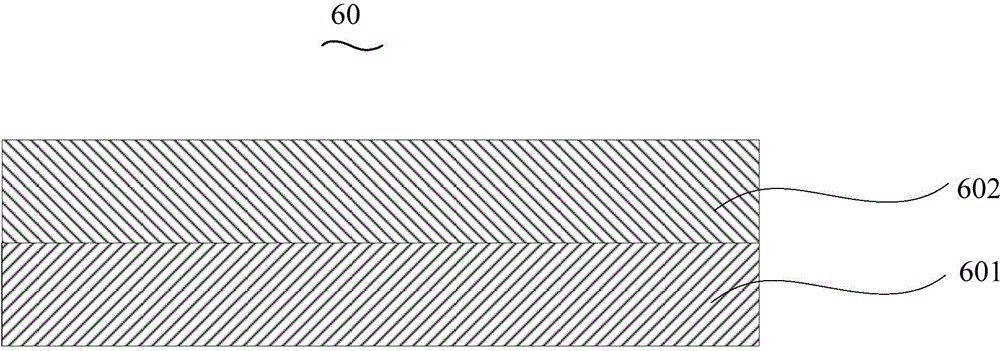

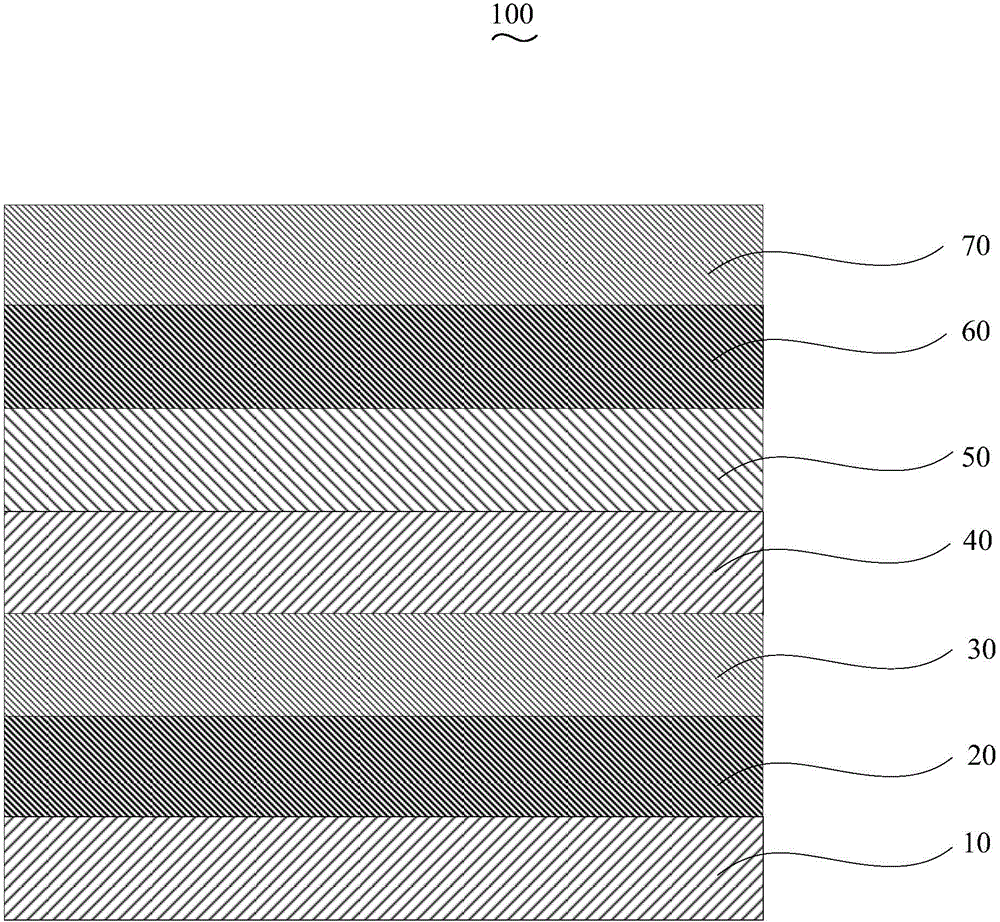

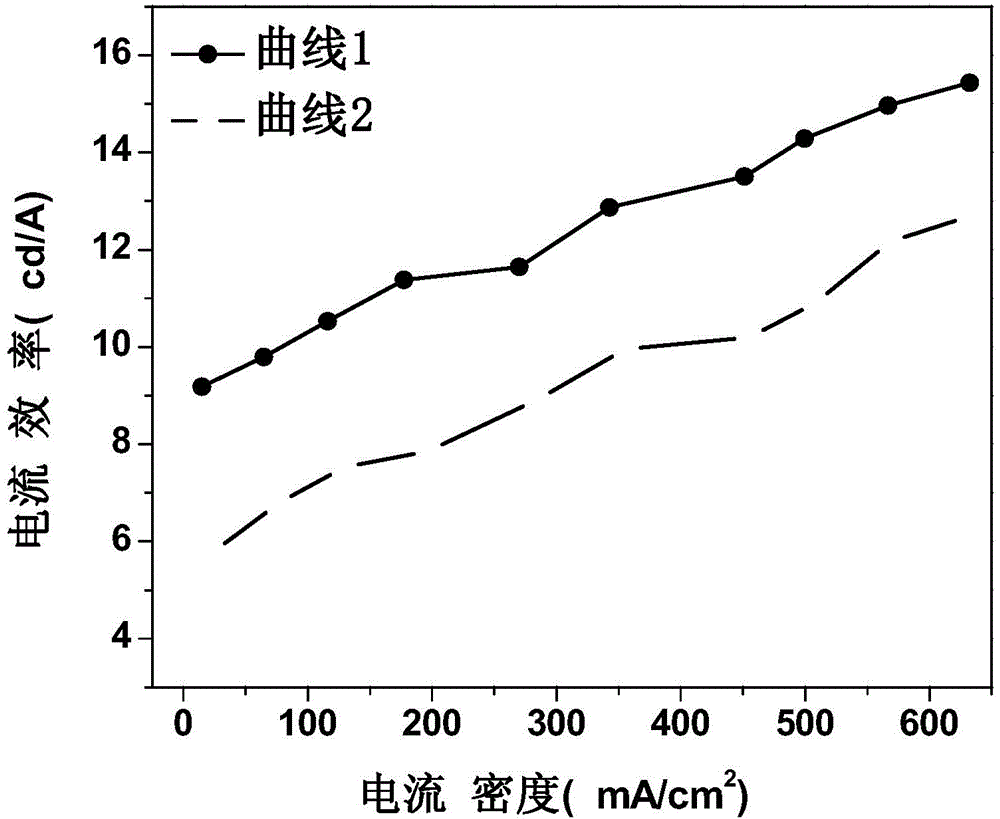

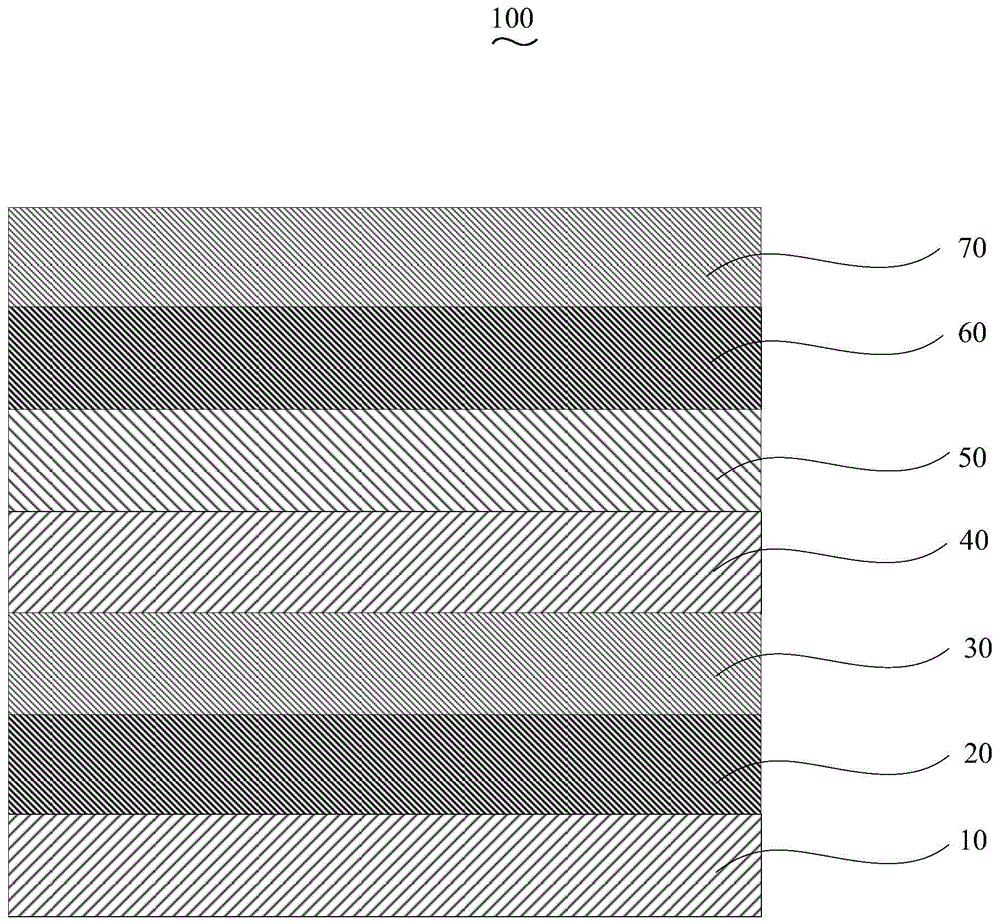

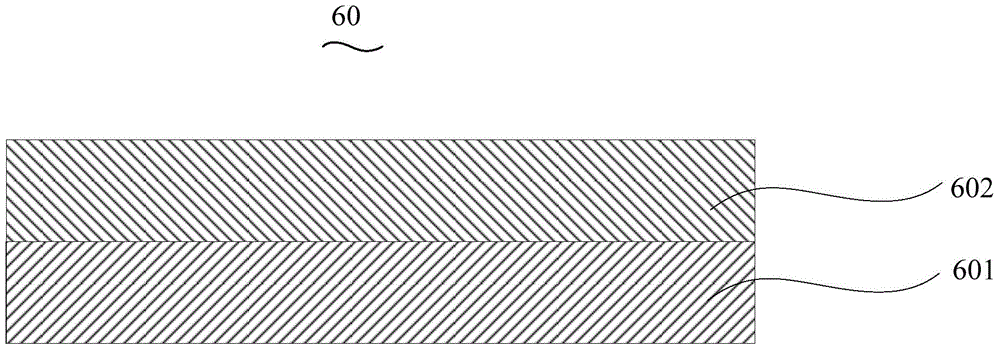

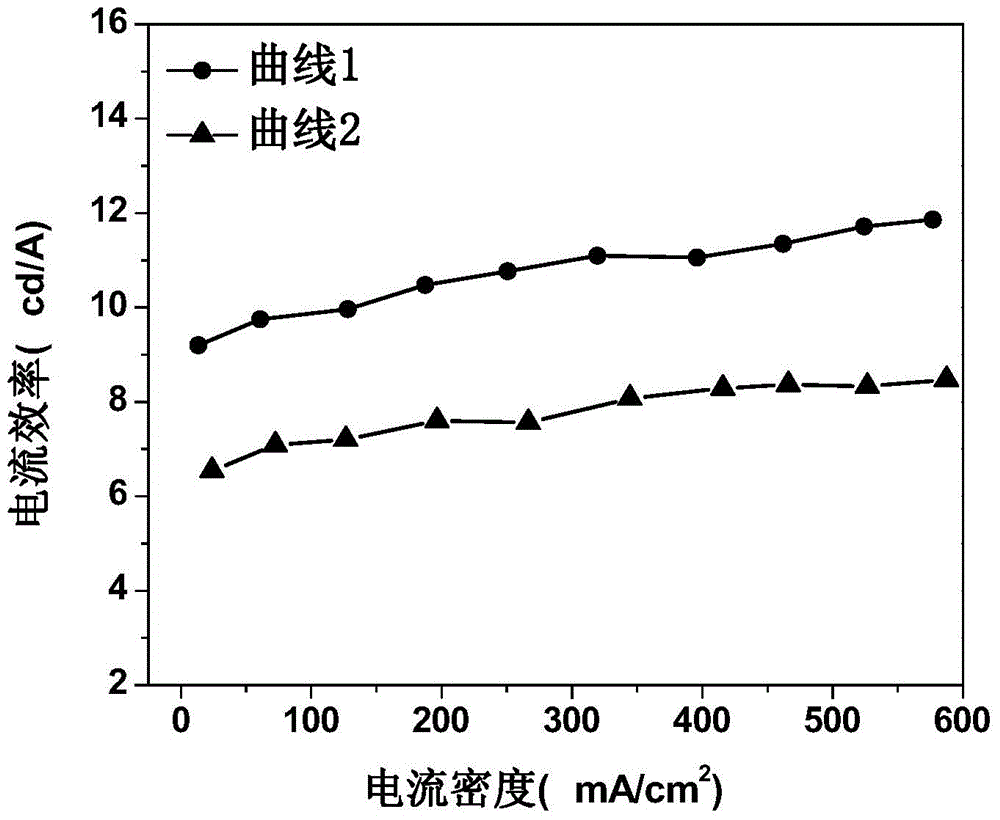

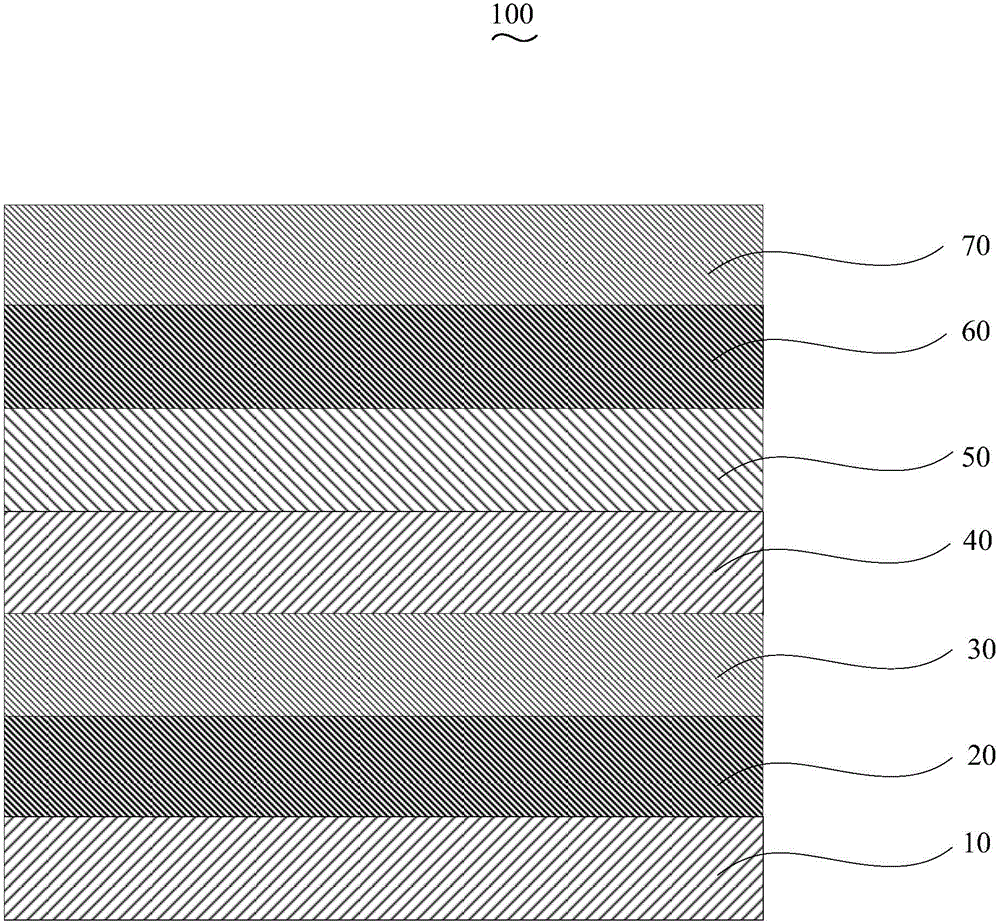

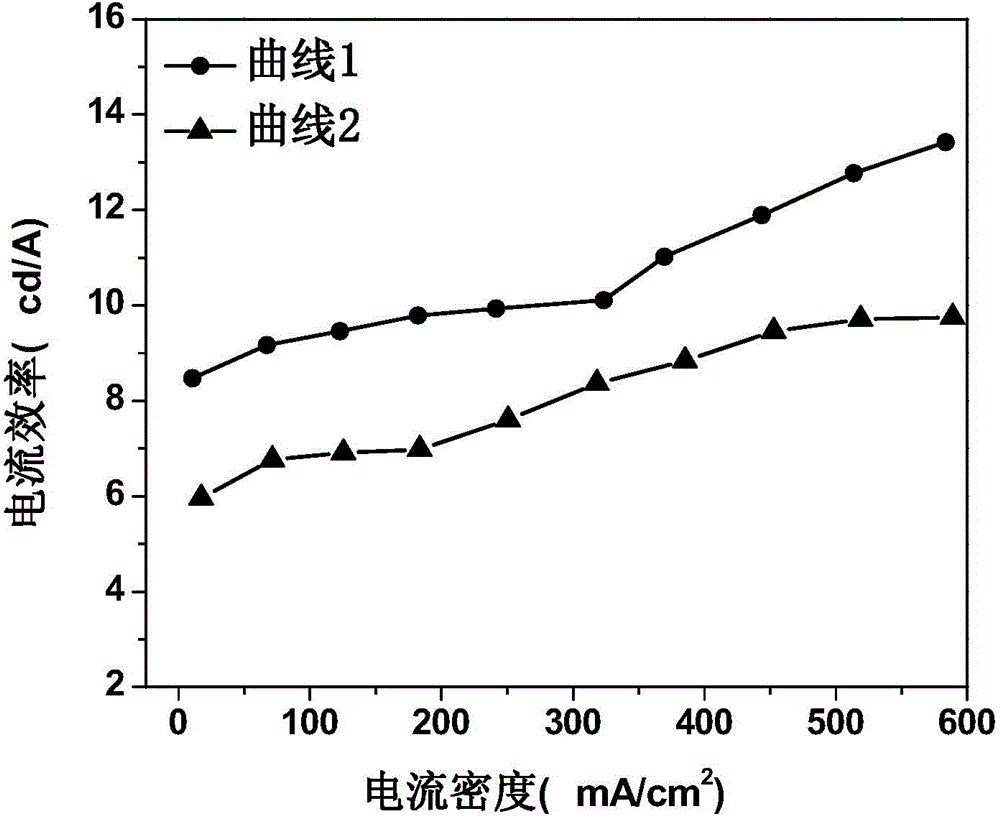

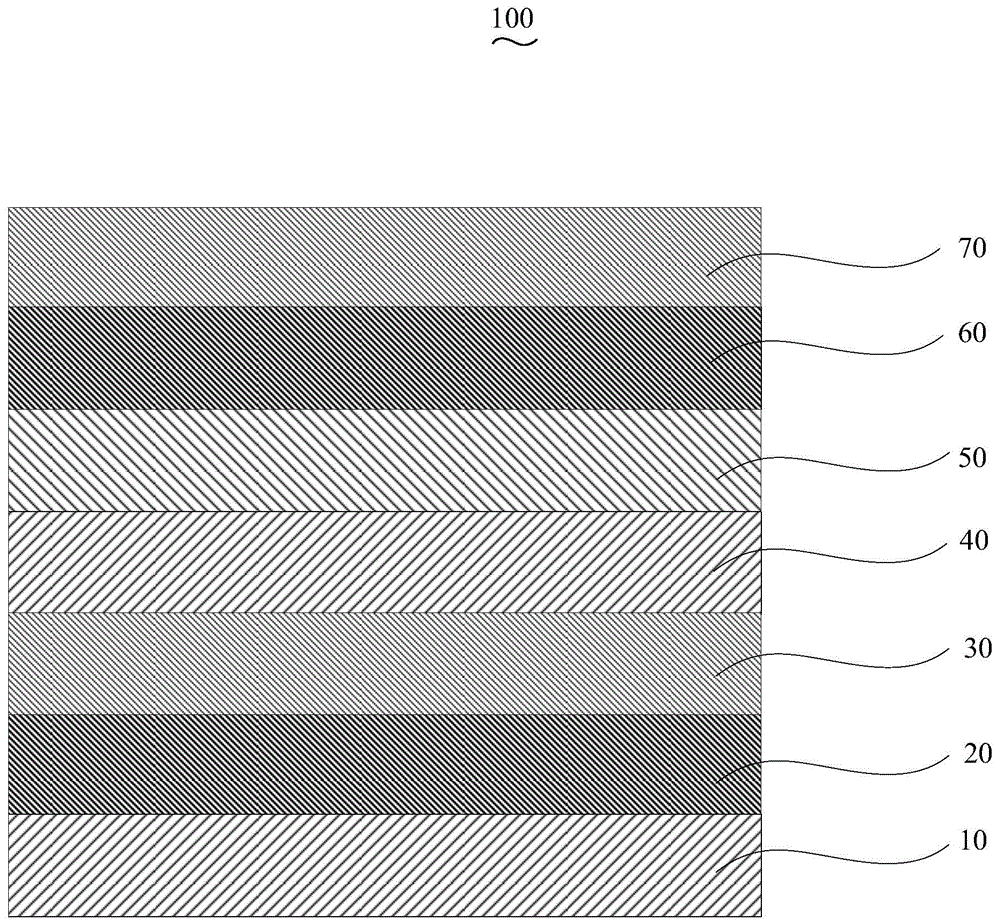

Organic electroluminescent device and manufacturing method thereof

InactiveCN103579508AImprove luminous efficiencyImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron transmissionCathode

An organic electroluminescent device comprises an anode substrate, a hole injection layer, a hole transmission layer, a luminous layer, an electron transmission layer, an electron injection layer and a cathode layer, wherein the anode substrate, the hole injection layer, the hole transmission layer, the luminous layer, the electron transmission layer, the electron injection layer and the cathode layer are stacked up in sequence. The materials of the electron transmission layer include an electron transmission material and first alkali carbonate doped in the electron transmission material, the doped mass percent concentration of the first alkali carbonate is 3%-8%. The materials of the electron injection layer include a main material, an n-type material and second alkali carbonate, the n-type material and the second alkali carbonate are jointly doped in the main material, and the doped mass percent concentration of the second alkali carbonate is 5%-10%. The first alkali carbonate and the second alkali carbonate are respectively selected from one of lithium carbonate, sodium carbonate, potassium carbonate, rubidium carbonate and cesium carbonate. The organic electroluminescent device is higher in luminous efficiency. In addition, a manufacturing method for the organic electroluminescent device is further provided.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

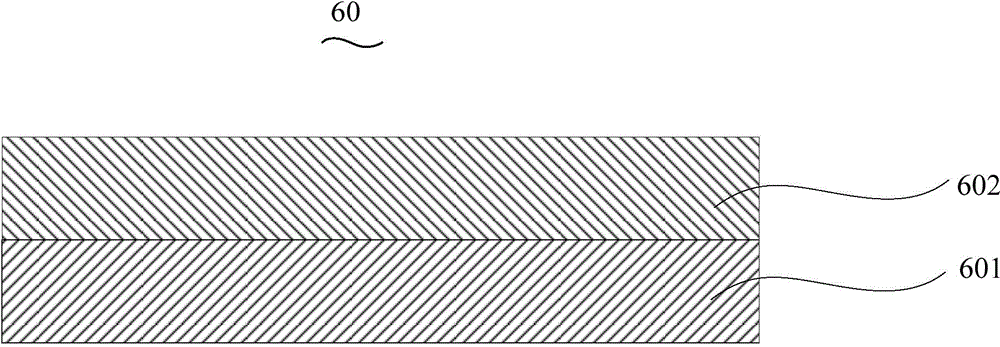

Organic electroluminescent device and manufacturing method thereof

InactiveCN104659227AEasy injectionIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium sulfateRubidium carbonate

The invention discloses an organic electroluminescent device and a manufacturing method thereof. The organic electroluminescent device comprises a glass substrate, a conductive anode, a hole injection layer, a hole transmission layer, a luminous layer, an electron transmission layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer comprises a rhenium compound doped layer, a rubidium compound layer and a metal layer which are stacked in sequence; the rhenium compound doped layer is arranged on the surface of the electron transmission layer and made from a mixed material formed by mixing a rhenium compound with a bipolar organic material at a mass ratio of (1:1) to (4:1); the rubidium compound layer is made from rubidium carbonate, rubidium chloride, rubidium nitrate or rubidium sulfate; the metal layer is made from low-work-function metal with the work function ranging from -2.0 eV to -3.5 eV. The electron injection layer can effectively improve the luminous efficiency of the device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

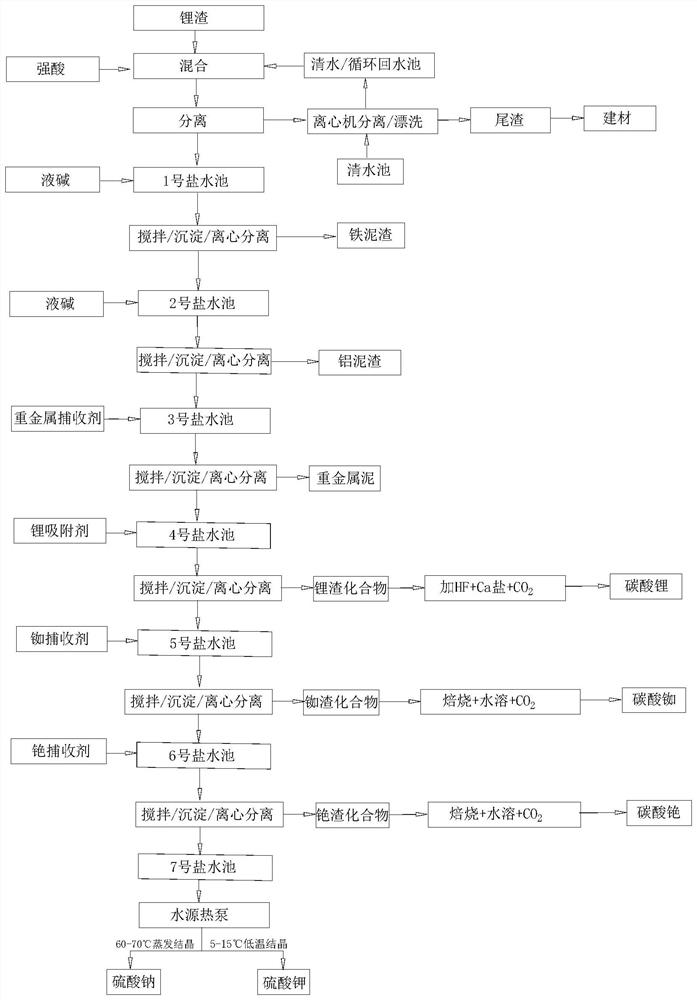

Lithium slag solid waste resource recycling process

PendingCN114702048AHigh recovery rateEfficient use ofAlkali metal sulfite/sulfate purificationRubidium/caesium/francium compoundsAluminum IonSlag

The invention relates to the technical field of lithium slag solid waste recycling, and discloses a lithium slag solid waste resource recycling process which comprises the following steps: S1, acid dissolution and separation: uniformly mixing lithium slag with water to infiltrate the lithium slag, and adding strong acid or composite acid to dissolve metal oxide in the lithium slag to generate acid salt; hydrolyzing to precipitate insoluble substances, and separating to remove insoluble and insoluble solids; s2, iron element removal: adding liquid caustic soda into the mixed salt solution, stirring, adjusting the pH value to 3-3.5, and centrifugally rinsing iron-containing precipitates to obtain iron mud; s3, aluminum element removal: adding liquid caustic soda into the mixed salt solution, stirring, adjusting to 6-7, completely precipitating aluminum ions, and separating the precipitate to obtain aluminum mud; s4, removal of heavy metal elements: a heavy metal collecting agent is added into the mixed salt solution, so that the heavy metals form insoluble substances, and the insoluble substances are precipitated, separated and removed; and S5, targeted separation: carrying out targeted separation on the residual salt solution to prepare potassium sulfate, sodium sulfate, lithium carbonate, cesium carbonate and rubidium carbonate.

Owner:珠海广隆新材料科技有限公司

Organic electroluminescence device and preparation method thereof

InactiveCN104659277ALower injection barrierImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundGlass transition

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a ternary doped layer and a cesium salt doped layer; the ternary doped layer comprises a rubidium compound material, a zinc oxide material and an electron transport material I; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the glass transition temperature of the electron transport material I is 50-100 DEG C; the cesium salt doped layer comprises a cesium salt material and an electron transport material II doped in the cesium salt material; the glass transition temperature of the electron transport material II is 50-100 DEG C; the cesium salt material is at least one of cesium fluoride, cesium carbonate, cesium azide and cesium chloride. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for improving stability of mixed halogen perovskite

ActiveCN112625680ALow costEasy to getLuminescent compositionsDidodecyldimethylammonium bromideEthyl acetate

The invention discloses a method for improving the stability of mixed halogen perovskite. The method comprises the steps of mixing and dissolving mixed lead halide and tetra-n-octyl ammonium bromide in toluene to obtain a solution A; dissolving cesium carbonate and rubidium carbonate in n-caprylic acid to obtain a solution B; dissolving formamidine acetate in n-caprylic acid to obtain a solution C; dissolving didodecyl dimethyl ammonium bromide into methylbenzene to obtain a solution D; and mixing the solution B and the solution C, then rapidly adding the mixture into the solution A, adding the solution D under the conditions of room temperature and magnetic stirring, and adding ethyl acetate for extraction to finally obtain the mixed halogen perovskite. By processing according to the method, the obtained mixed halogen perovskite material has relatively good stability and photoelectric property, and has relatively high brightness and stability when being applied to preparation of a perovskite light-emitting device.

Owner:FUZHOU UNIV +1

Preparation method of high-purity anhydrous rubidium iodide

PendingCN113735144AHigh purityImprove conversion efficiencyRubidium/caesium/francium compoundsRubidium carbonateRubidium iodide

The invention discloses a preparation method of high-purity anhydrous rubidium iodide. The preparation method of the high-purity anhydrous rubidium iodide comprises the following steps: A, under the condition of normal temperature, adding 400-600g of rubidium carbonate into a reaction container, slowly adding pure water with the mass liquid-solid ratio of (2-4): 1 while stirring, and stirring the solution for 10-30 minutes until the rubidium carbonate is completely dissolved; B, at normal temperature, filtering the solution obtained in the step A while the solution is hot by adopting a sand core funnel of 1-5 microns, and removing alkaline insoluble substances and other impurities to obtain a clear and transparent rubidium carbonate solution; C, at normal temperature, slowly pouring an iodine simple substance with the molar ratio of Li to I being 1:1 into the rubidium carbonate solution obtained in the step B under a stirring condition to carry out disproportionation reaction, and stirring the solution for 15-20 min to generate a dark brown solution. The preparation method of the high-purity anhydrous rubidium iodide is simple and practical in process, low in equipment investment, low in production cost, high in yield, high in economic value, small in environmental pollution and high in production safety.

Owner:GANFENG LITHIUM CO LTD

Organic electroluminescence device and preparation method thereof

InactiveCN104659251AIncrease transfer rateLower injection barrierSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundIodide

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer is made of one or more rubidium compound materials, one or more copper oxide materials and one or more of metal materials; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the copper oxide material(s) is / are one or more of cuprous iodide, cuprous oxide, copper phthalocyanine and cupric oxide; the work function of the metal materials is -4.0 eV to -5.5 eV. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

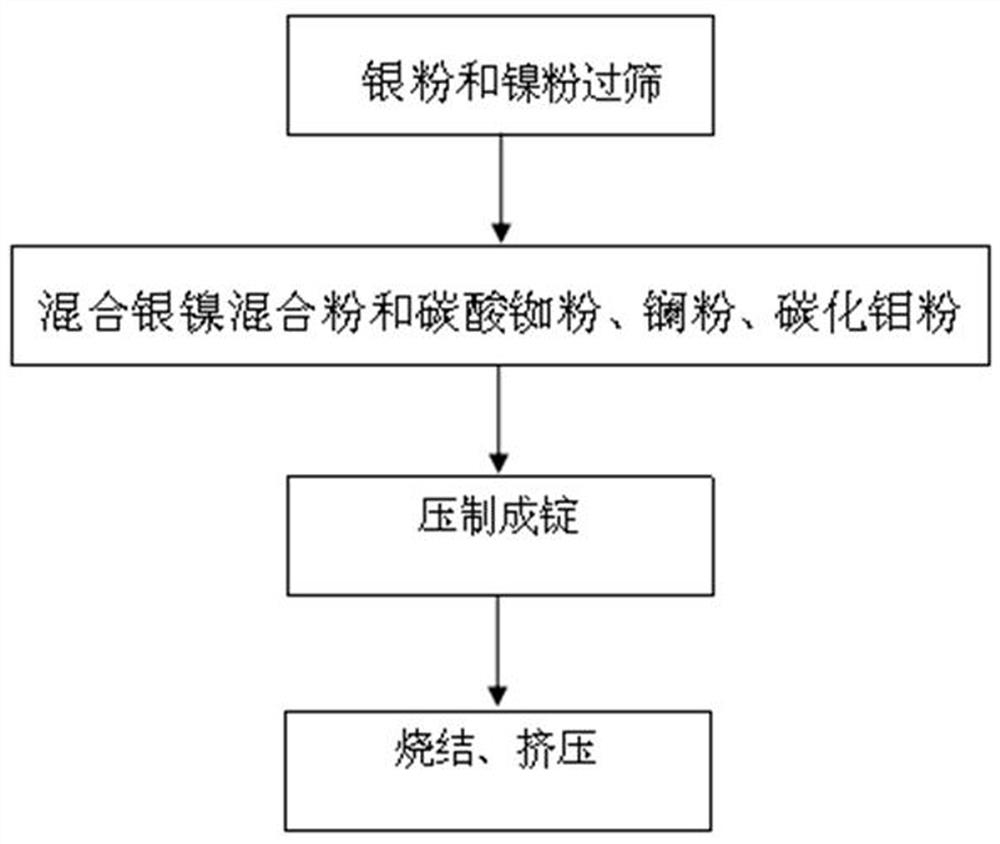

Preparation method of silver-nickel electric contact material

The invention discloses a preparation method of a silver-nickel electric contact material. The preparation method comprises the following steps that (1) silver powder and nickel powder are sieved, andsilver-nickel mixed powder is prepared; (2) the silver-nickel mixed powder prepared in step (1) is mixed with rubidium carbonate powder, lanthanum powder and molybdenum carbide powder in a plough shovel type powder mixing machine, and silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide mixed powder is prepared; (3) the silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide mixedpowder prepared in step (2) is pressed into an ingot on a cold isostatic press, and a silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide ingot is prepared; and (4) the silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide ingot prepared in step (3) is sintered and extruded into a wire or a plate under nitrogen protection, the wire is used for cold heading to make rivet contacts,the plate is rolled and punched to produce sheet contacts, and the silver-nickel electric contact material is prepared. The preparation method is simple in preparation process, short in production period, high in material utilization rate, suitable for large-scale production and capable of being widely applied and popularized.

Owner:浙江耐迩合金科技有限公司

Organic electroluminescence device and preparation method thereof

InactiveCN104659219ALower injection barrierImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSodium bicarbonateRubidium compound

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a rubidium compound doped layer and a passive material layer; the rubidium compound doped layer comprises a rubidium compound material and a sodium salt material doped in the rubidium compound material; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the sodium salt material is at least one of sodium carbonate, sodium chloride, sodium bicarbonate and sodium fluoride; the passive material layer is made at least one of silicon dioxide, aluminum oxide, nickel oxide and copper oxide. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Production method capable of increasing refractive indexes of float glass

The invention relates to a production method capable of increasing refractive indexes of float glass. The production method includes uniformly mixing quartz sand, aluminum oxide, soda, calcium carbonate, magnesium carbonate, rubidium carbonate, strontium carbonate, niobium pentoxide, osmium dioxide and polyethylene wax with one another to obtain mixtures and then feeding the mixtures into a float glass melting furnace; melting the mixtures in the float glass melting furnace at the high temperature to obtain melt; clarifying and homogenizing the melt and then enabling the melt to flow into a work pool; enabling the melt to flow into forming tin bath from a trough in the work pool and forming a strap-shaped continuous glass plate; carrying out annealing working procedures and cutting working procedures on the strap-shaped continuous glass plate to obtain the float glass which is a finished product. The production method capable of increasing the refractive indexes of the float glass has the advantages that the refractive indexes of the float glass can be increased and can reach 1.611, and the content of bubble in the float glass can be reduced.

Owner:TG ANHUI GLASS

High-toughness packaging material

InactiveCN105860887AImprove temperature resistanceHigh mechanical strengthNon-macromolecular adhesive additivesSynthetic resin layered productsComposite filmDipropylene glycol diacrylate

The invention discloses a high-toughness packaging material which sequentially comprises an aluminum foil composite film layer, an adhesive layer and a cyclopentadiene film layer from inside to outside. The adhesive layer is prepared by the following steps: adding dipropanediol diacrylate and maleic anhydride into butanone, and reacting under reflux for 50 minutes; adding tetrazole and ethoxylated trimethylolpropane triacrylate, and reacting under reflux for 20 minutes; sequentially adding 1,3,5-triglycidyl-S-triazinyltrione and diethyl phosphite, and reacting under reflux for 2 hours; adding cyanochitosan, polydimethylsiloxane and 2-hexanone, and reacting under reflux for 1.5 hours; and finally, adding rubidium carbonate, continuing reacting for 1 hour to obtain the adhesive layer. By using the reasonable structural design and adhesive layer, the high-toughness packaging material disclosed by the invention has the advantages of favorable mechanical strength, high temperature resistance, favorable packaging protecting property, no pollution and the like, and is convenient to use.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

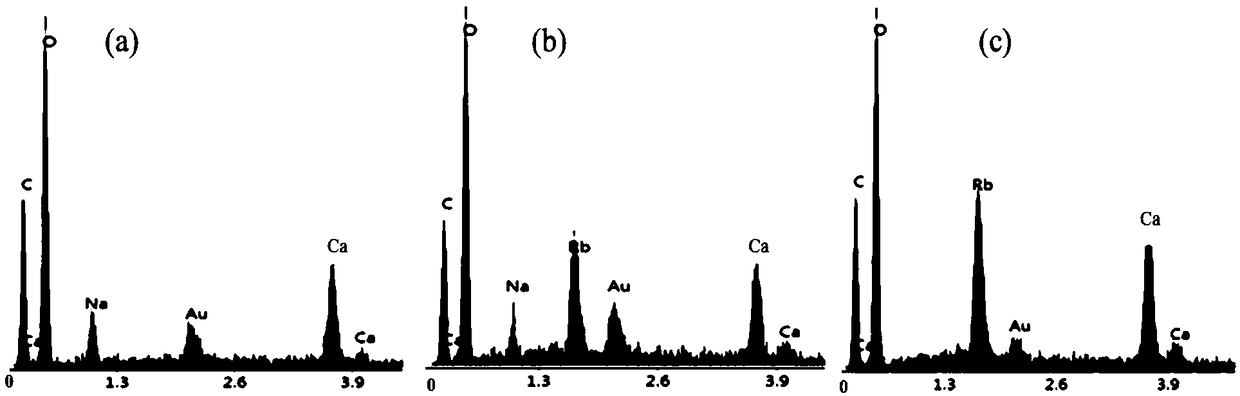

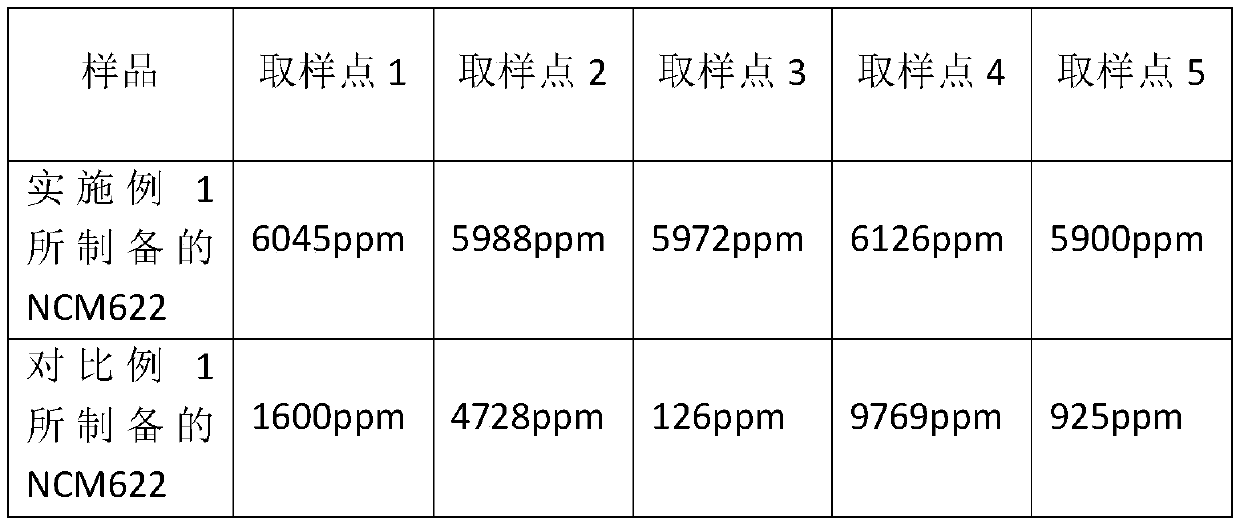

Method for preparing ternary cathode material of rubidium-doped lithium ion battery

PendingCN110400925AIncrease productivityEvenly distributedCell electrodesRubidium carbonateIron removal

The invention discloses a method for preparing a ternary cathode material of a rubidium-doped lithium ion battery. The method comprises the following steps of: weighing an appropriate amount of rubidium carbonate as a rubidium source and dissolving the rubidium carbonate in pure water to obtain an aqueous solution of rubidium, according to the doping amount of rubidium being in a range of 0.1%-1%(wt%), calculating the desired ternary material precursor, adding the ternary material precursor into the aqueous solution of rubidium, and adding pure water to a suitable solid content; evaporating and drying the above solid-liquid mixture to obtain mixed rubidium powder B; and mixing the mixed rubidium powder B with a lithium source, and performing high-temperature sintering, crushing and iron removal and sieving to obtain a ternary material of a rubidium-doped lithium ion battery. The method for preparing a ternary cathode material of a rubidium-doped lithium ion battery does not need an organic solution, is high in production efficiency, uniform in distribution of the rubidium of the ternary material and regular in shape.

Owner:深圳市新创材料科技有限公司

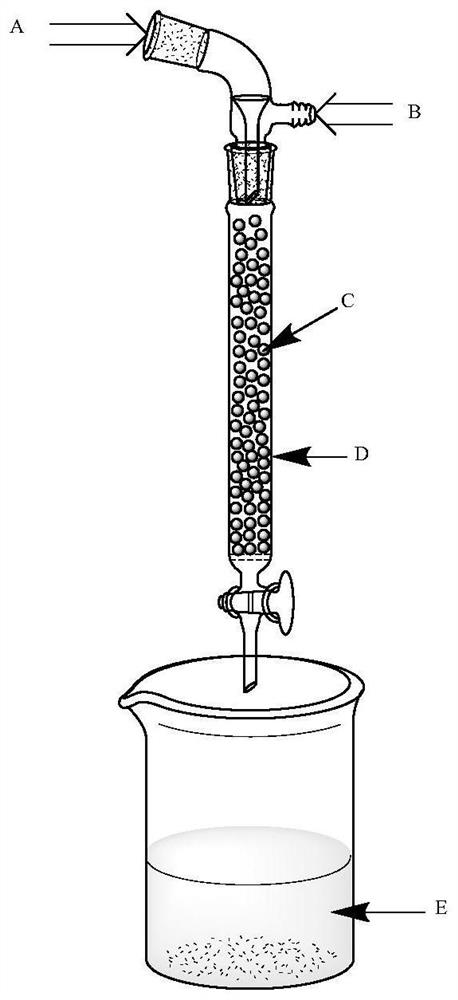

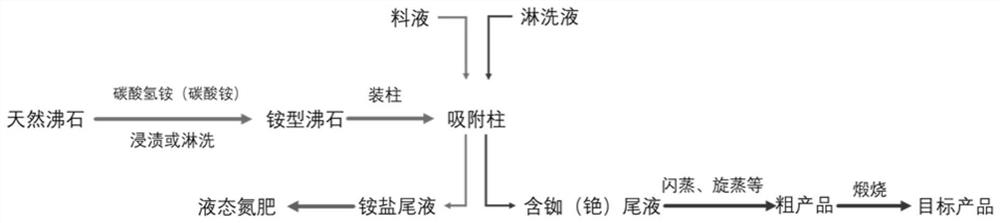

Preparation method of rubidium carbonate and/or cesium carbonate

PendingCN112479236AEasy to makeImprove structural strengthRubidium/caesium/francium compoundsRubidium carbonateNitrate salts

The invention discloses a preparation method of rubidium carbonate and / or cesium carbonate. The preparation method comprises the following steps: inputting a salt solution containing rubidium and / or cesium into an adsorption column filled with ammonium type natural zeolite for dynamic adsorption; taking an ammonium carbonate solution and / or an ammonium bicarbonate solution as eluent to elute the dynamically adsorbed adsorption column to obtain rubidium and / or cesium-containing tail liquid; and carrying out evaporative crystallization and calcination treatment on the obtained rubidium and / or cesium-containing tail liquid to obtain rubidium carbonate and / or cesium carbonate. The invention designs a preparation method for converting sulfate, nitrate and chloride of rubidium or cesium into carbonate. The method has the advantages of low cost, simple process flow and no pollution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Organic electroluminescence device and preparation method thereof

InactiveCN104659246AImprove conductivityImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingIron(III) sulfideRubidium compound

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer comprises a rubidium compound doped layer and a metal doped layer; the rubidium compound doped layer is made of a rubidium compound material and a molysite material doped in the rubidium compound material; the rubidium compound material is one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the molysite material is one or more of ferric chloride, ferric bromide and ferric sulfide; the metal doped layer is made of a first metal material and a second metal material doped in the first metal material; the work function of the first metal material is -2.0 eV to -3.5 eV; the work function of the second metal material is -4.0 eV to -5.5 eV. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic light-emitting device and manufacturing method thereof

InactiveCN104659215AEasy injectionIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundPhenanthroline

The invention discloses an organic light-emitting device, which comprises an anode, a hole injection layer, a hole transmission layer, a light emitting layer, an electron transport layer, an electron injection layer and a cathode laminated in sequence, wherein the electron injection layer is composed of a two-element doping layer and a rubidium compound layer; the two-element doping layer rubidium compound material and electron transport material; the rubidium compound material selects at least one from rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the electron transport material selects at least one from 4, 7-Diphenyl-1, 10-phenanthroline, 2-(4-tert-Butylphenyl)-5-(4-biphenyl)-1,3,4-oxadiazole, 8-Hydroxyquinoline aluminum salt and N-aryl benzimidazole; and the rubidium compound layer material is also the rubidium compound material. The above organic light-emitting device is high in light emitting efficiency. The invention also provides an organic light-emitting device manufacturing method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation method of biological active hydroxylamine oxalate vanadium complex crystal

InactiveCN104130282AHigh inhibition rateSimple methodMetabolism disorderGroup 5/15 element organic compoundsHydroxylamineAmmonium metavanadate

The invention discloses a preparation method of a biological active hydroxylamine oxalate vanadium complex crystal, and the method uses Rb <+ >ions as external balance ions for participating into the complex, and comprises the following steps: 1, at 0-4 DEG C, rubidium carbonate, ammonium metavanadate, oxalic acid, hydroxylamine hydrochloride and water are stirred and dissolved in a container I, the pH value of the solution is adjusted by a hydrochloric acid solution to obtain a pale yellow clear solution; 2, anhydrous alcohol is added into another container II, the container I filled with the reaction liquid in the step 1 is put in the container II, the container II is sealed, and placed in a refrigerator for standing for 2 to 4 days, and a colorless flaky crystal is precipitated on the container I bottom; and 3, the crystal precipitated on the container I bottom is taken out, washed with deionized water for a plurality of times, then is successively washed respectively with the anhydrous ethanol and ether for a plurality of times, and then is put in a dryer to obtain dry and pure crystal, namely the biological active hydroxylamine oxalate vanadium complex crystal. The obtained biological active hydroxylamine oxalate vanadium complex crystal is good in biological activity, and the preparation method is simple, easy in operation, and short in time.

Owner:EAST CHINA NORMAL UNIV

Organic electroluminescence device and preparation method thereof

InactiveCN104659253AIncrease transfer rateLow melting pointSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundAzide

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer is made of one or more rubidium compound materials, one or more cesium salt materials and titanium dioxide; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the cesium salt material(s) is / are one or more of cesium fluoride, cesium carbonate, cesium azide and cesium chloride. The light efficiency of the organic electroluminescence device is relatively high. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659224AIncrease transfer rateImprove injection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLithium oxideLithium chloride

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are stacked in sequence, wherein the electron injection layer consists of a rubidium compound doped layer and a metal doped layer; the rubidium compound doped layer comprises a rubidium compound material and a metal material I doped in the rubidium compound material; the rubidium compound material is at least one of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the work function of the metal material I is -2.0 eV to -3.5 eV; the metal doped layer comprises a metal material II and a lithium salt material doped in the metal material II; the work function of the metal material II is -2.0 eV to -3.5 eV; the lithium salt material is at least one of lithium oxide, lithium fluoride, lithium chloride and lithium bromide. The organic electroluminescence device is relatively high in luminescence efficiency. The invention further provides a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic electroluminescence device and preparation method thereof

InactiveCN104659222AEasy injectionIncrease transfer rateSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundPhenanthroline

An organic electroluminescence device comprises an anode, a hole injection layer, a hole transporting layer, a luminous layer, an electron transporting layer, an electron injection layer and a cathode which are overlapped in sequence, wherein the electron injection layer comprises a two-element-doped layer and a metal doped layer; the two-element-doped layer is made of one or more rubidium compound materials and an organosilicon small molecular material; the rubidium compound material(s) is / are one or more of rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; the energy gap of the organosilicon small molecular material is -3.5 eV to -5.5 eV; the metal doped layer is made of one or more of metal materials and one or more electron transporting materials; the work function of the metal materials is -2.0 eV to -3.5 eV; the electron transporting material(s) is / are one or more of 4,7-diphenyl-1,10-phenanthroline, 2-(4'-tert-butylphenyl)-5-(4'-biphenyl)-1,3,4-oxadiazole, 8-hydroxyquinoline aluminum, and N-aryl benzimidazole.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Organic light-emitting device and manufacturing method thereof

InactiveCN104659216AEasy to injectEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingRubidium compoundMetallic materials

The invention discloses an organic light-emitting device, which comprises an anode, a hole injection layer, a hole transmission layer, a light emitting layer, an electron transport layer, an electron injection layer and a cathode laminated in sequence, wherein the electron injection layer is composed of a three-element doping layer and a titanium dioxide layer; the three-element doping layer comprises rubidium compound material, electron transport material and metal material; the rubidium compound material selects at least one from rubidium carbonate, rubidium chloride, rubidium nitrate and rubidium sulfate; and the electron transport material selects at least one from 4, 7-Diphenyl-1, 10-phenanthroline, 2-(4-tert-Butylphenyl)-5-(4-biphenyl)-1,3,4-oxadiazole, 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline, and 2,2'-(1,3-Phenylene)-bis [5-(4-tert-butylphenyl)-1,3,4-oxadiazole]. The above organic light-emitting device is high in light emitting efficiency. The invention also provides an organic light-emitting device manufacturing method.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

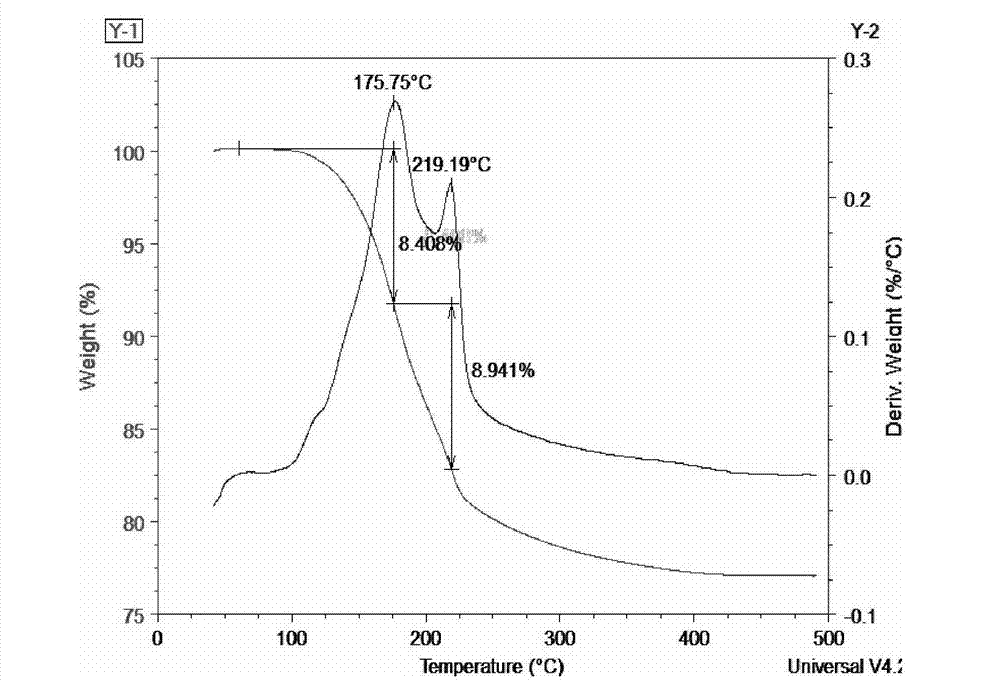

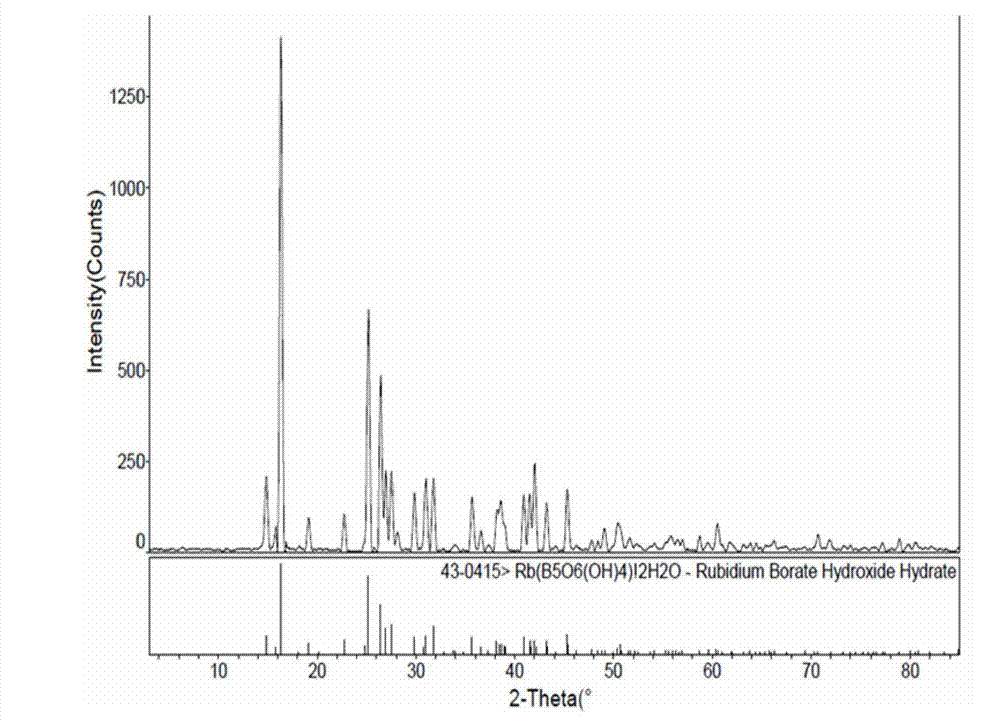

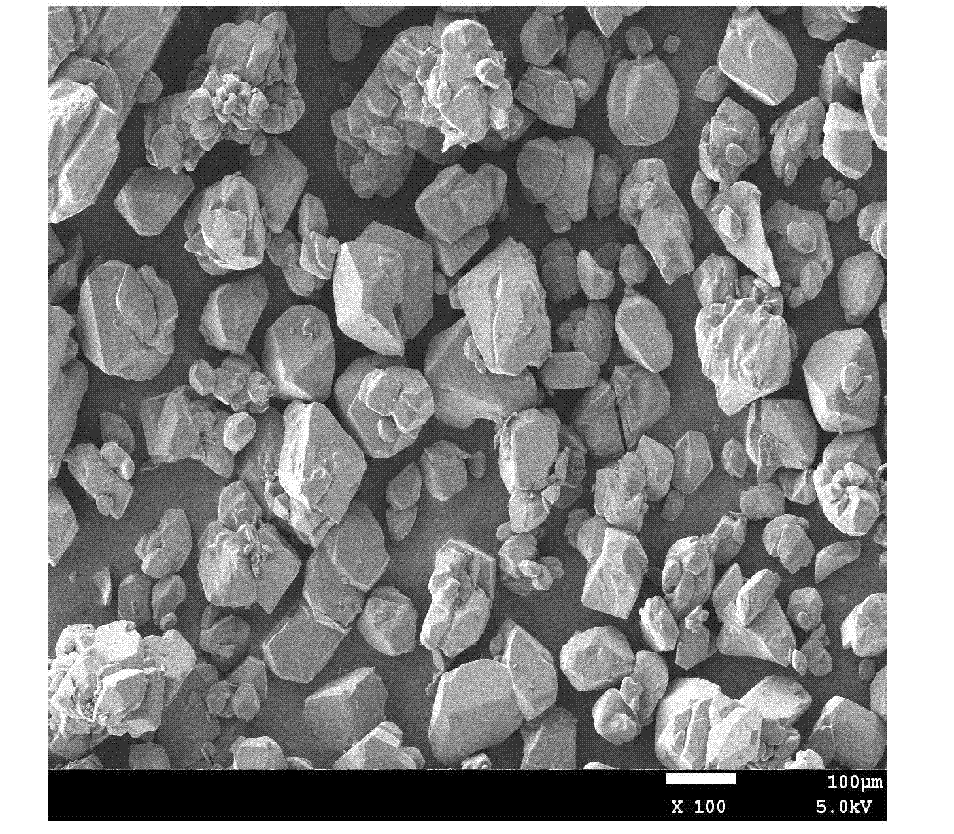

Method for preparing rubidium pentaborate

InactiveCN103172078AShort reaction timeShort synthesis timeBoratesRubidium carbonateRubidium compound

The invention relates to a method for preparing rubidium pentaborate, and belongs to the technical field of a rubidium compound. The method for preparing the rubidium pentaborate disclosed by the invention comprises the following steps of a, adding rubidium carbonate to 20-30wt% of boric acid solution to agitate, so as to obtain reaction liquid, wherein the weight of the rubidium carbonate is 7.5-11.5% of that of water in the boric acid solution; and b, filtering the reaction liquid obtained in step a, and drying a filter cake. The method disclosed by the invention has the advantages of being short in synthesis time, high in yield, fast and simple, environment-friendly, economic and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com