Method for preparing ternary cathode material of rubidium-doped lithium ion battery

A lithium-ion battery, ternary material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of inaccurate measurement and dry mixing, and achieve uniform distribution, regular morphology, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

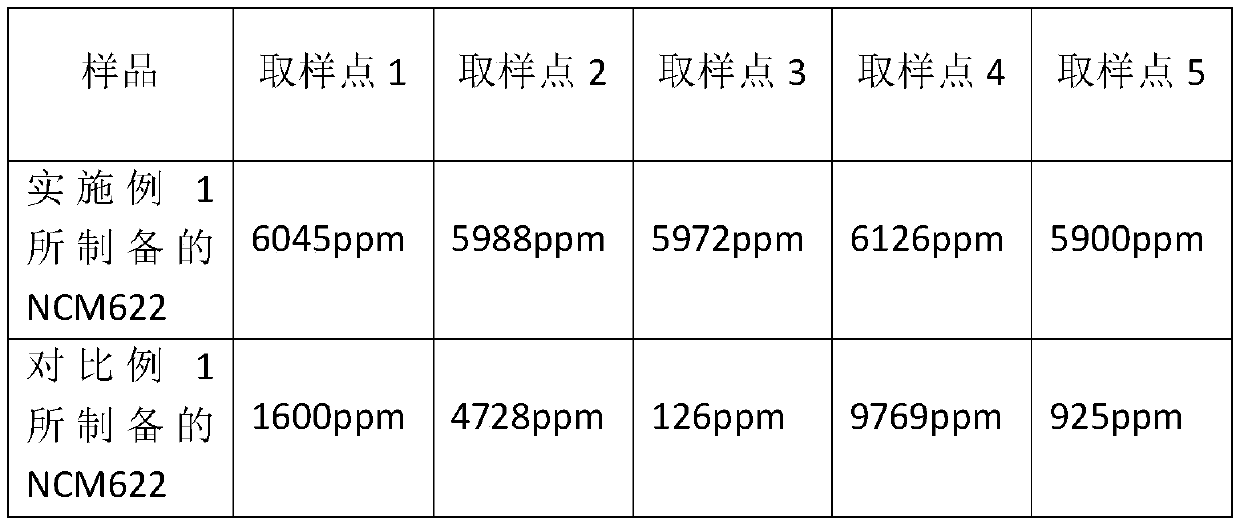

[0027] About 1g of rubidium carbonate was roughly weighed and dissolved in 9ml of pure water to obtain aqueous solution A of rubidium. The rubidium carbonate content of solution A was tested by ICP to be 9.6%. Weigh 56.4g NCM622 precursor (Ni 0.6 co 0.2 mn 0.2 (OH) 2 ) Add 5g of aqueous solution A, and add 51.4ml of pure water to adjust the solid-liquid ratio to 50%, to obtain solid-liquid mixture B. The solid-liquid mixture B was continuously stirred at 105 °C until the water was completely evaporated to dryness, and a uniformly mixed powder C of rubidium carbonate and NCM622 precursor was obtained. Weigh 23g of lithium carbonate and powder C, mix them uniformly in a ball mill, and then sinter at 900°C for 16 hours to obtain a rubidium-doped NCM622 positive electrode material.

Embodiment 2

[0035] Roughly weigh about 0.5g of rubidium carbonate and dissolve it in 9.5ml of pure water to obtain aqueous solution A of rubidium. The content of rubidium carbonate in solution A is 4.5% by ICP: Weigh 55.5g NCM811 precursor (Ni 0.8 co 0.1 mn 0.1 (OH) 2 ) Add 5g of aqueous solution A, and add 25ml of pure water to adjust the solid-liquid ratio to 65%, to obtain solid-liquid mixture B. The solid-liquid mixture B was continuously stirred at 115 °C until the water was completely evaporated to dryness, and a uniformly mixed powder C of rubidium carbonate and NCM811 precursor was obtained. Weigh 25.94g of lithium hydroxide and powder C, mix them uniformly in a ball mill, and then sinter at 750°C for 16 hours to obtain a rubidium-doped NCM811 positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com