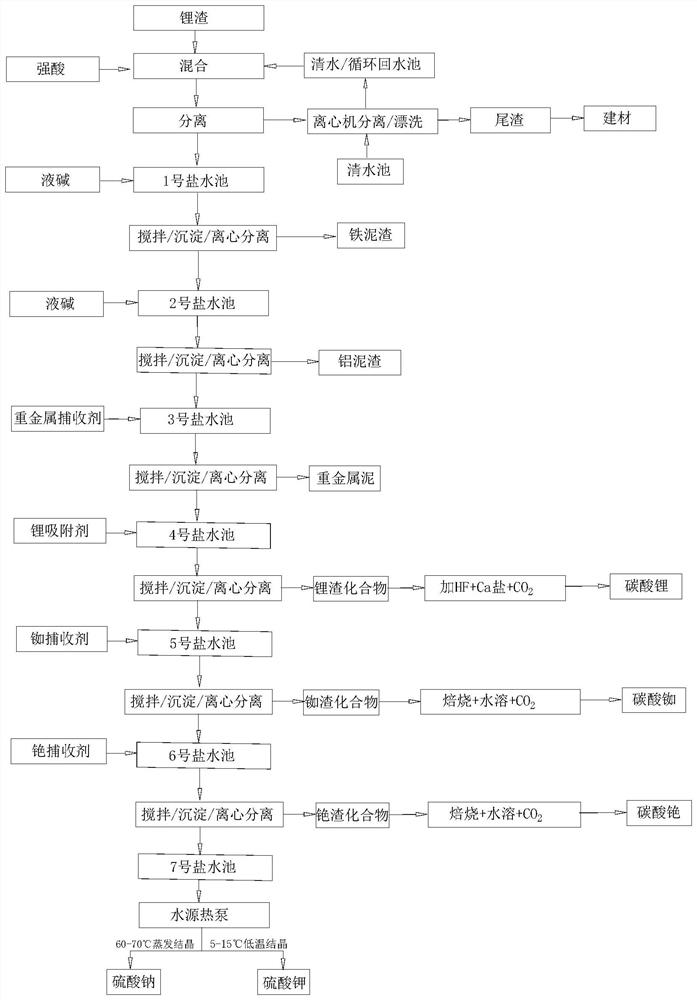

Lithium slag solid waste resource recycling process

A technology of resource utilization and lithium slag, applied in the direction of inorganic chemistry, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of lithium slag recovery rate and low utilization value, pollution, waste of resources, etc., to improve the comprehensive utilization value , Protect the environment and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: The present embodiment provides a lithium slag solid waste recycling process, which is carried out according to the following steps:

[0054] S1. Acid dissolution and separation: Mix 1t lithium slag with water evenly, so that the lithium slag is completely infiltrated with water, and then add sulfuric acid. The amount of sulfuric acid is 25% of the solid content of the lithium slag, so that the lithium, sodium, potassium, Metal oxides such as rubidium, cesium, magnesium, iron, aluminum, and zinc can be completely dissolved to form acid salts; in this embodiment, sulfuric acid uses a by-product acid with a concentration of 50wt%, and the by-product acid is more expensive than reagent-grade sulfuric acid. Appropriate to reduce recycling costs and improve resource utilization. Specifically, lithium slag undergoes a series of chemical reactions in the mixed solution of water and sulfuric acid, and the representative reactions are as follows:

[0055] Na 2 O+...

Embodiment 2

[0073] Embodiment 2: The present embodiment provides a lithium slag solid waste recycling process, which is carried out according to the following steps:

[0074] S1. Acid dissolution and separation: Mix 1t lithium slag with water evenly, so that the lithium slag is completely infiltrated by water, then add sulfuric acid and hydrofluoric acid, the molar ratio of sulfuric acid and hydrofluoric acid is 1:1, sulfuric acid and hydrofluoric acid The amount used is 25% of the solid content of the lithium slag, so that metal oxides such as lithium, sodium, potassium, rubidium, cesium, magnesium, iron, aluminum, and zinc are completely dissolved in the lithium slag to form acid salts; in this embodiment, sulfuric acid is used The by-product acid with a concentration of 50wt% is more suitable for the price of the by-product acid than the reagent grade sulfuric acid, so as to reduce the recovery cost and improve the resource utilization rate. Specifically, lithium slag undergoes a serie...

Embodiment 3

[0093] Embodiment 3: The present embodiment provides a lithium slag solid waste recycling process, which is carried out according to the following steps:

[0094] S1. Acid dissolution and separation: Mix 1t of lithium slag with water evenly, so that the lithium slag is completely infiltrated by water, and then add hydrofluoric acid. The amount of hydrofluoric acid is 25% of the solid content of the lithium slag, so that the lithium, Metal oxides such as sodium, potassium, rubidium, cesium, magnesium, iron, aluminum, and zinc are completely dissolved to form acid salts; in this embodiment, hydrofluoric acid uses a by-product acid with a concentration of 50 wt%, and the by-product acid is compared with reagents The price of grade hydrofluoric acid is more suitable to reduce the cost of recycling and improve the utilization rate of resources. Specifically, lithium slag undergoes a series of chemical reactions in the mixed solution of water and sulfuric acid, and the representativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com