Organic electroluminescent device and manufacturing method thereof

An electroluminescence device and a luminescence technology, which are applied in the manufacture of organic semiconductor devices, electric solid state devices, and semiconductor/solid state devices, can solve the problems of low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

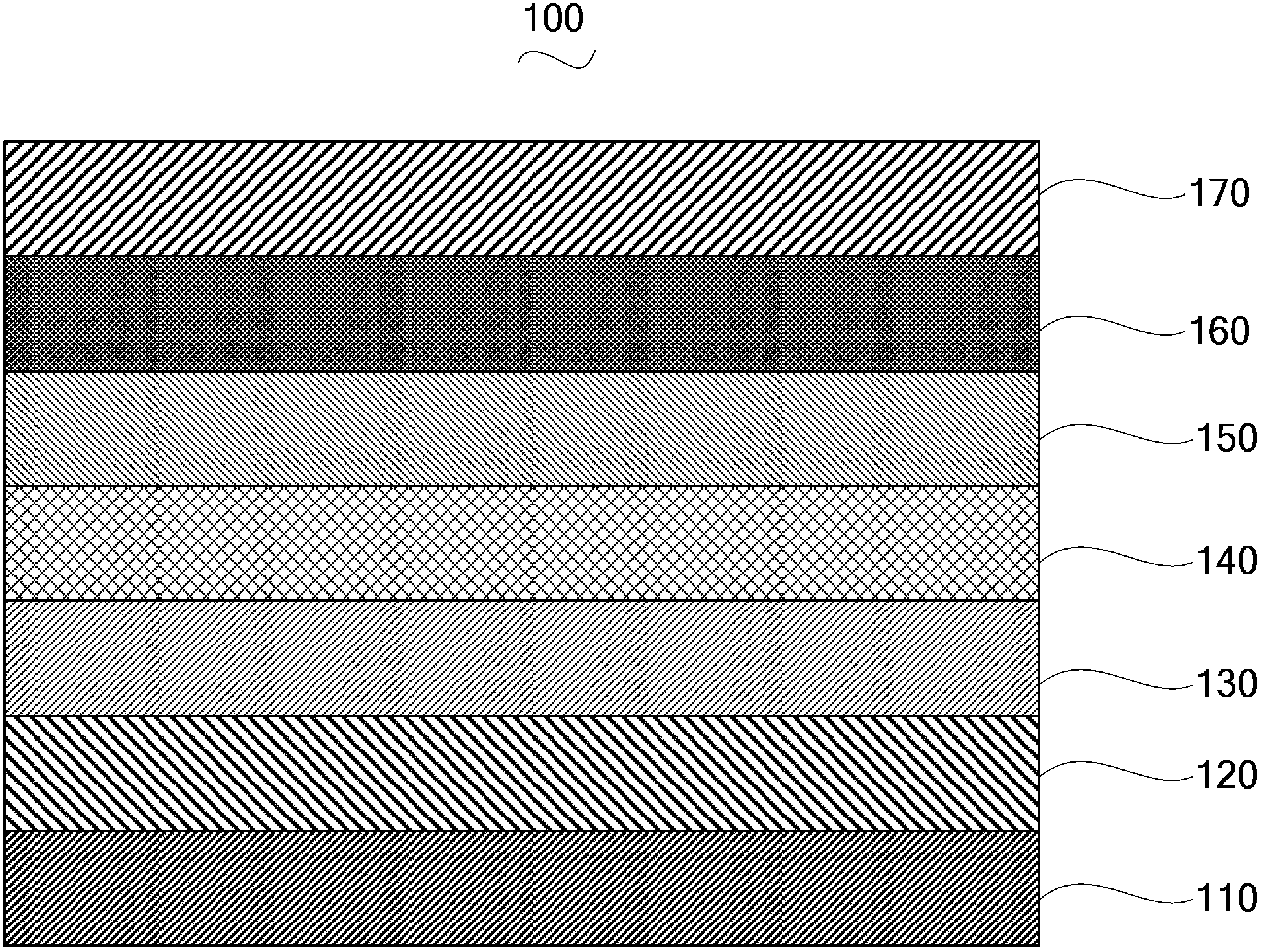

preparation example Construction

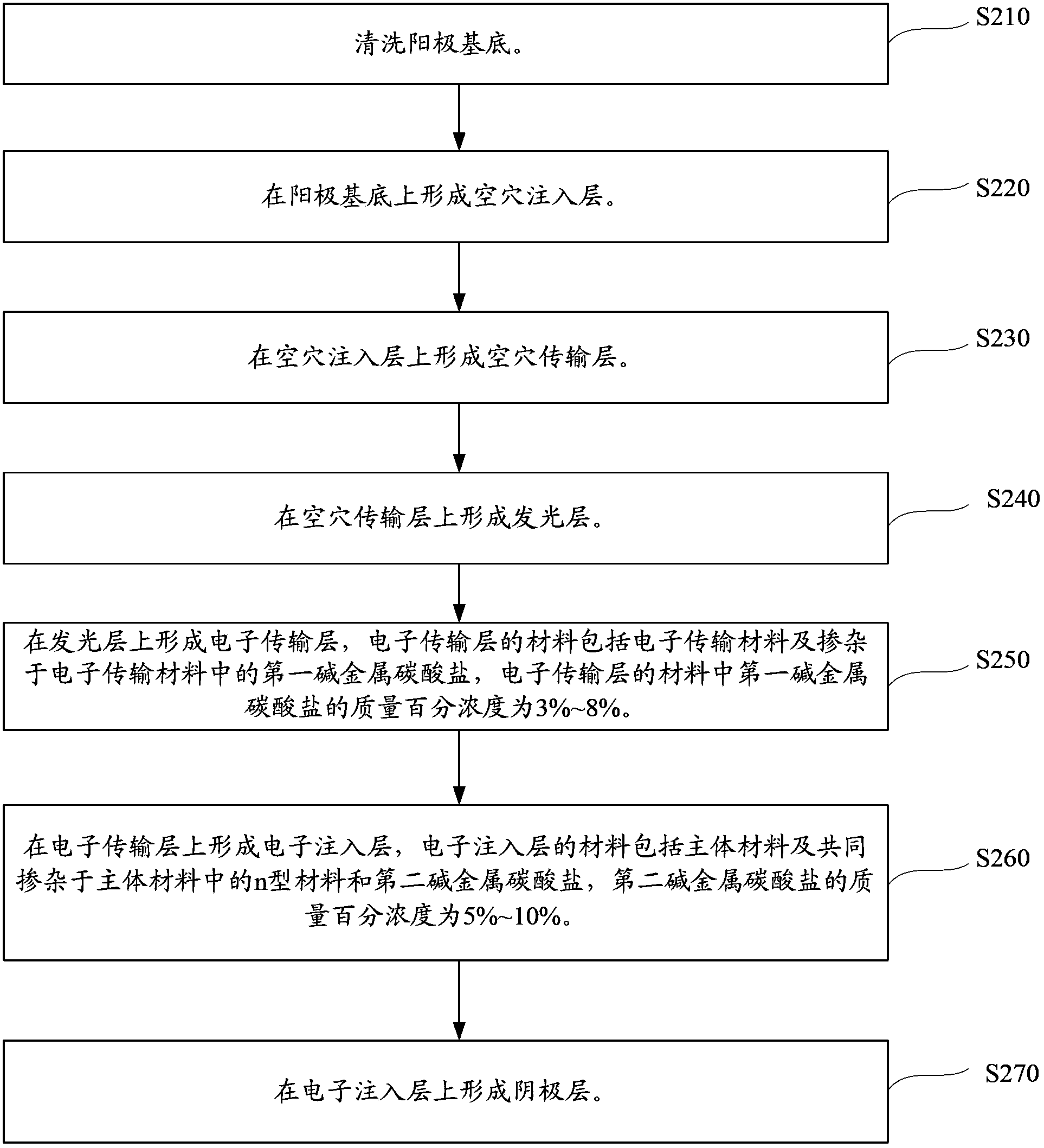

[0042] Such as figure 2 As shown, a method for preparing an organic electroluminescent device 100 in one embodiment includes the following steps:

[0043] Step S210 : cleaning the anode substrate 110 . In a specific embodiment, the cleaning step of the anode substrate 110 includes: firstly cleaning the anode substrate 110 in ultrasonic waves for 5 minutes with detergent, then cleaning in ultrasonic waves with deionized water for 5 minutes, then cleaning in ultrasonic waves with acetone for 5 minutes, and finally Use ethanol to clean in ultrasonic for 5 minutes, and stop for 5 minutes after each cleaning; wash three times according to the above sequence, and dry the cleaned anode substrate 110 to obtain a clean anode substrate 110 . Dust and organic matter on the surface of the anode substrate 110 are removed through the above cleaning.

[0044] Wherein, after the anode substrate 110 is cleaned, a surface activation treatment step for the anode substrate 110 is also included...

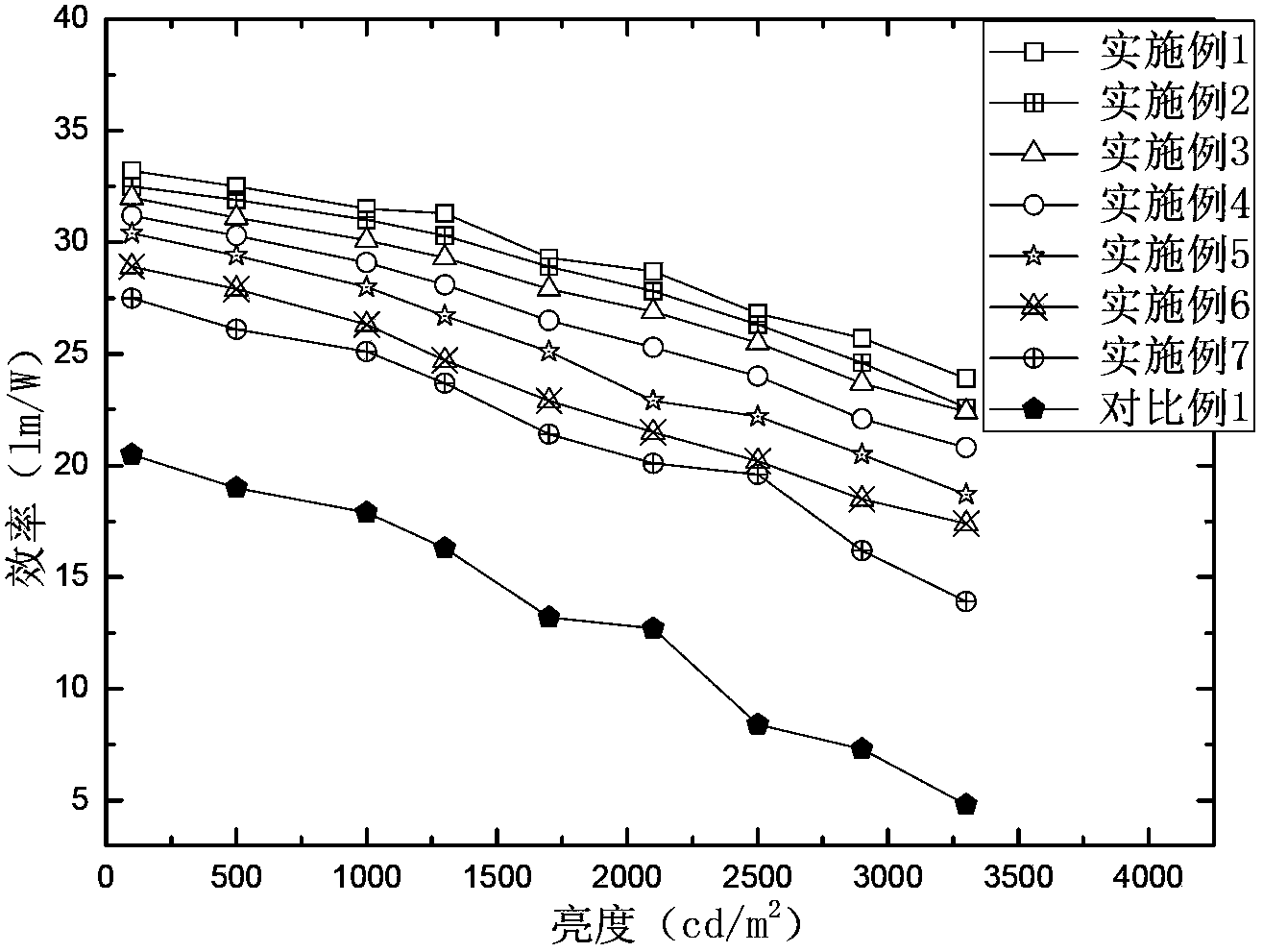

Embodiment 1

[0061] The structure of the organic electroluminescent device of the present embodiment is: ITO / NPB:MoO 3 / NPB / TPBI:Ir(ppy) 3 / Bphen:Li 2 CO 3 / Bphen:Li 3 N:Li 2 CO 3 / Ag.

[0062] The preparation of the organic electroluminescent device of this embodiment is as follows:

[0063] (1) Cleaning the ITO anode substrate: First, use detergent to clean in ultrasonic for 5 minutes, then use deionized water to clean in ultrasonic for 5 minutes, then use acetone to clean in ultrasonic for 5 minutes, and finally use ethanol to clean in ultrasonic for 5 minutes Minutes, stop for 5 minutes after each cleaning; wash three times according to the above sequence, and dry the cleaned ITO anode substrate to obtain a clean ITO anode substrate; treat the cleaned ITO anode substrate with UV-OZONE for 30 minutes. The thickness of the ITO anode substrate is 100 nm.

[0064] (2) Vacuum evaporation on the ITO anode substrate to form a hole injection layer, wherein the material of the hole inje...

Embodiment 2

[0072] The structure of the organic electroluminescent device of the present embodiment is: FTO / TCTA:WO 3 / TCTA / TPBI:Ir(ppy) 3 / BCP:Na 2 CO 3 / BCP:CsF:Na 2 CO 3 / Al.

[0073] The preparation of the organic electroluminescent device of this embodiment is as follows:

[0074] (1) Cleaning the FTO anode substrate: First, use detergent to clean in ultrasonic for 5 minutes, then use deionized water to clean in ultrasonic for 5 minutes, then use acetone to clean in ultrasonic for 5 minutes, and finally use ethanol to clean in ultrasonic for 5 minutes Minutes, stop for 5 minutes after each cleaning; wash three times according to the above sequence, and dry the cleaned FTO anode substrate to obtain a clean FTO anode substrate; treat the cleaned FTO anode substrate with UV-OZONE for 30 minutes. The thickness of the FTO anode substrate is 150 nm.

[0075] (2) Vacuum evaporation on the FTO anode substrate to form a hole injection layer, wherein the material of the hole injection l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com