Preparation method of rubidium carbonate and/or cesium carbonate

A technology of rubidium carbonate and cesium carbonate, applied in chemical instruments and methods, rubidium/cesium/francium compounds, inorganic chemistry, etc., can solve the problems of high price of auxiliary reagents, troublesome reprocessing methods, introduction of other impurities, etc., and achieve equipment cost Low requirements, low cost, and no three-waste discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

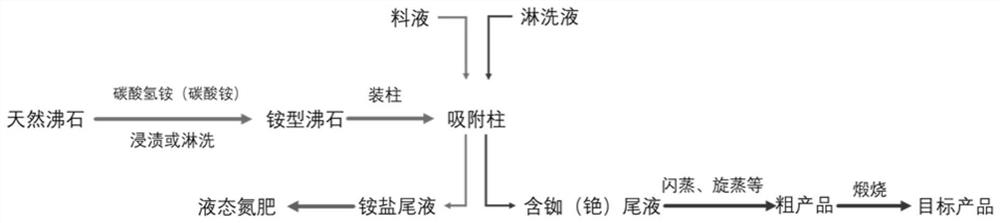

[0024] An aspect of the embodiments of the present invention provides a kind of preparation method of rubidium carbonate and / or cesium carbonate, it comprises:

[0025] Provide ammonium type natural zeolite as adsorbent;

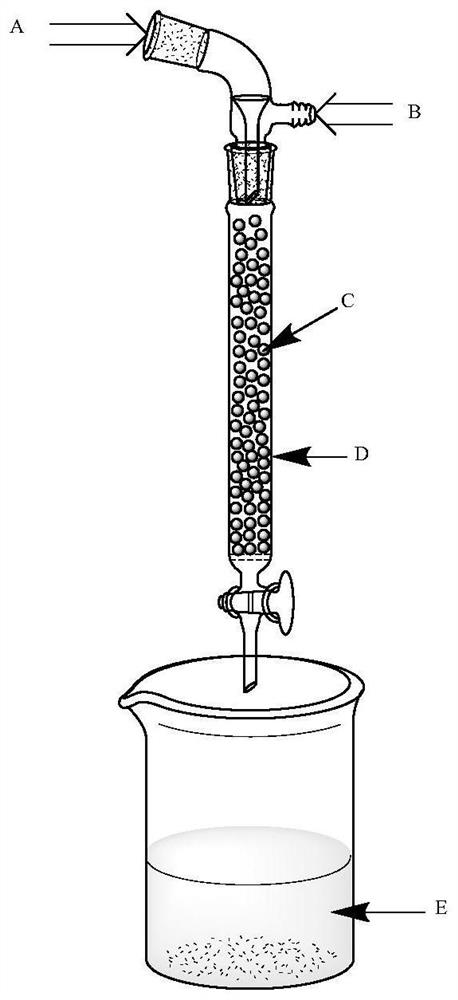

[0026] Inputting a salt solution containing rubidium and / or cesium into the adsorption column filled with the ammonium-type natural zeolite for dynamic adsorption;

[0027] Using ammonium carbonate solution and / or ammonium bicarbonate solution as eluent to elute the adsorption column after dynamic adsorption to obtain rubidium and / or cesium tail liquid;

[0028] And, the obtained tail liquid containing rubidium and / or cesium is subjected to evaporation, crystallization and calcination to obtain rubidium carbonate and / or cesium carbonate.

[0029] In some more specific embodiments, the ammonium-type natural zeolite is prepared by ammonium bicarbonate and / or ammonium carbonate modified natural zeolite; wherein, the preparation method of the ammonium-type natu...

Embodiment 1

[0054] Embodiment 1: cesium sulfate solution is converted into cesium carbonate through zeolite

[0055] Take 1000g of the purchased natural zeolite, soak it in 500mL of ammonium bicarbonate with a concentration of 2mol / L for 24h to obtain ammonium-type natural zeolite, then put the ammonium-type natural zeolite into a custom-made adsorption column with an inner diameter of 3.75cm, and use a peristaltic pump to The cesium sulfate solution of 9.3mg / L is pumped in from the top of the adsorption column at a pump speed of 5mL / min. When cesium ions are detected to flow out, the dynamic adsorption is stopped, and then the eluent (ammonium bicarbonate) is pumped in at a flow rate of 2mL / min. ), until no cesium ion flows out, the collected adsorption liquid tail liquid and eluent tail liquid (containing cesium tail liquid) are respectively 7.2L and 3.8L; then the eluent tail liquid (containing cesium tail liquid) is evaporated Crystallization, drying treatment, and calcination treatme...

Embodiment 2

[0059] Embodiment 2: cesium sulfate solution is converted into cesium carbonate through zeolite

[0060] Take 1000g of purchased natural zeolite in different batches, soak it in 500mL ammonium bicarbonate with a concentration of 2mol / L for 24h to obtain ammonium-type natural zeolite, then put the ammonium-type natural zeolite into a custom-made adsorption column with an inner diameter of 3.75cm, Pump 9.3mg / L cesium sulfate solution from the top of the adsorption column through a peristaltic pump at a pump speed of 5mL / min. When cesium ions are detected to flow out, stop the dynamic adsorption, and then pump in the eluent at a flow rate of 2mL / min. (2mol / L ammonium bicarbonate), until no cesium ion flows out, the adsorption liquid tail liquid and eluent tail liquid (containing cesium tail liquid) that collect are respectively 6.7L and 4.5L; (Cesium-containing tail liquid) is evaporated and crystallized, dried, and calcined at 300°C for 12 hours to obtain the product cesium carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com