Preparation method of silver-nickel electric contact material

An electrical contact material, silver-nickel technology, is applied in the field of preparation of silver-nickel electrical contact materials to achieve the effects of enhancing the resistance to arc burnout, short production cycle and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

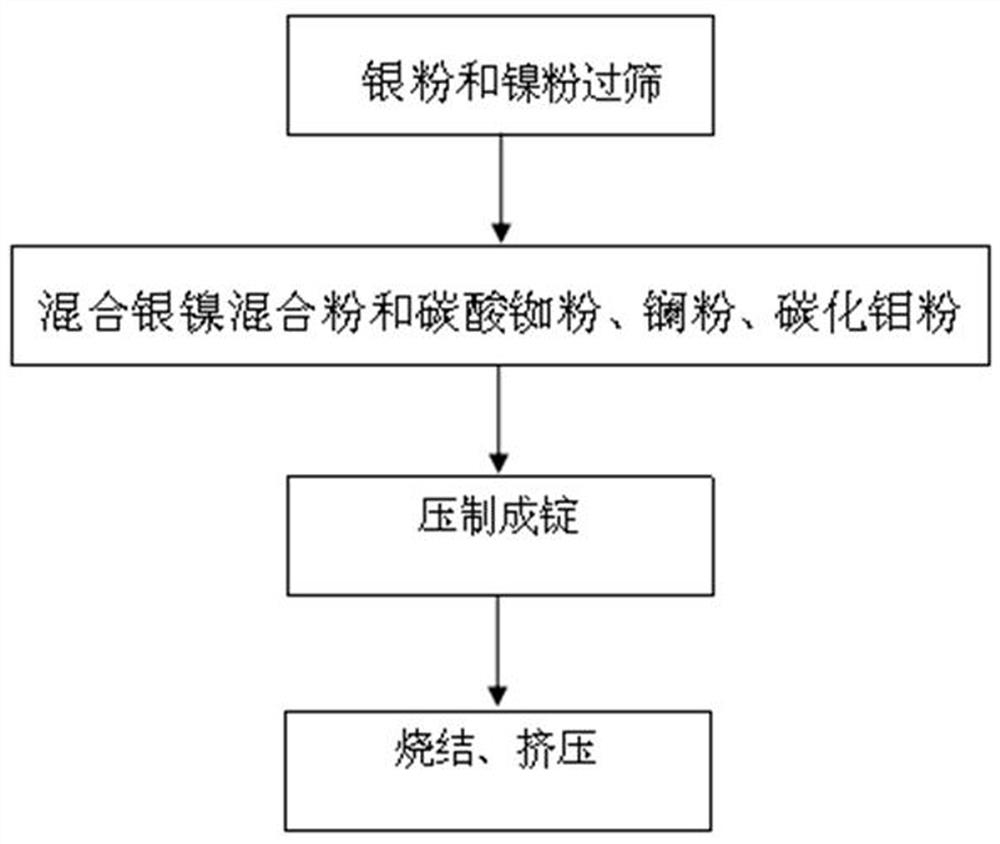

[0032] The preparation method of described silver-nickel electric contact material, comprises the following steps:

[0033] (1) Pass 42-86 parts of silver powder and 10-25 parts of nickel powder through a 100-200 mesh sieve to obtain mixed silver-nickel mixed powder;

[0034] (2) Mix the mixed silver-nickel mixed powder prepared in step (1) with 6-12 parts of rubidium carbonate powder, 0.4-0.7 parts of lanthanum powder, and 2-9 parts of molybdenum carbide powder in a plow-shovel type powder mixer for 3- 5h, silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide mixed powder was obtained;

[0035] (3) Press the silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide mixed powder prepared in step (2) into an ingot under a pressure of 200-300 MPa and a holding time of 12-36 seconds on a cold isostatic press, Prepare silver-nickel-rubidium carbonate-lanthanum-molybdenum carbide ingot;

[0036] (4) Sinter the silver-nickel-rubidium carbonate-lanthanum-molybdenum carb...

Embodiment 1

[0039] A silver-nickel electrical contact material, comprising the following raw materials in parts by weight: 45 parts of silver powder, 11 parts of nickel powder, 6 parts of rubidium carbonate powder, 0.4 part of lanthanum powder, and 3 parts of molybdenum carbide powder;

[0040] The particle size of the silver powder is 0.6-9.6 μm;

[0041] The particle size of the nickel powder is 0.4-12.2 μm;

[0042] The particle size of the rubidium carbonate powder is 0.2-7.1 μm;

[0043] The particle size of the lanthanum powder is 0.8-6.2 μm;

[0044] The particle size of the molybdenum carbide powder is 0.3-7.8 μm;

[0045] The preparation method of described silver-nickel electric contact material, comprises the following steps:

[0046] (1) Pass 45 parts of silver powder and 11 parts of nickel powder through a 100-mesh sieve to obtain mixed silver-nickel mixed powder;

[0047] (2) Mix the mixed silver-nickel mixed powder prepared in step (1) with 6 parts of rubidium carbonate...

Embodiment 2

[0051] A silver-nickel electrical contact material, comprising the following raw materials in parts by weight: 65 parts of silver powder, 18 parts of nickel powder, 10 parts of rubidium carbonate powder, 0.6 part of lanthanum powder, and 6 parts of molybdenum carbide powder;

[0052] The particle size of the silver powder is 0.8-9.2 μm;

[0053] The particle size of the nickel powder is 0.6-12.1 μm;

[0054] The particle size of the rubidium carbonate powder is 0.42-7.2 μm;

[0055] The particle size of the lanthanum powder is 1-5.9 μm;

[0056] The particle size of the molybdenum carbide powder is 0.4-8.2 μm;

[0057] The preparation method of described silver-nickel electric contact material, comprises the following steps:

[0058] (1) Pass 65 parts of silver powder and 18 parts of nickel powder through a 200-mesh sieve to obtain mixed silver-nickel mixed powder;

[0059] (2) Mix the mixed silver-nickel mixed powder prepared in step (1) with 10 parts of rubidium carbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com