Method for preparing rubidium pentaborate

A technology of pentaboric acid and rubidium carbonate, applied in the directions of borates, boron oxy compounds, etc., can solve the problems of many by-products, low yield, long synthesis time, etc., and achieve the advantages of short synthesis time, high yield and shortened reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of rubidium pentaborate of the present invention comprises the steps:

[0028] a, rubidium carbonate is added in the boric acid solution of 20~30wt%, stirs, obtains reaction liquid; Wherein, the weight of rubidium carbonate is 7.5~11.5% of the water weight in the boric acid solution;

[0029] b. Filter the reaction solution obtained in step a, and dry the filter cake to obtain final product.

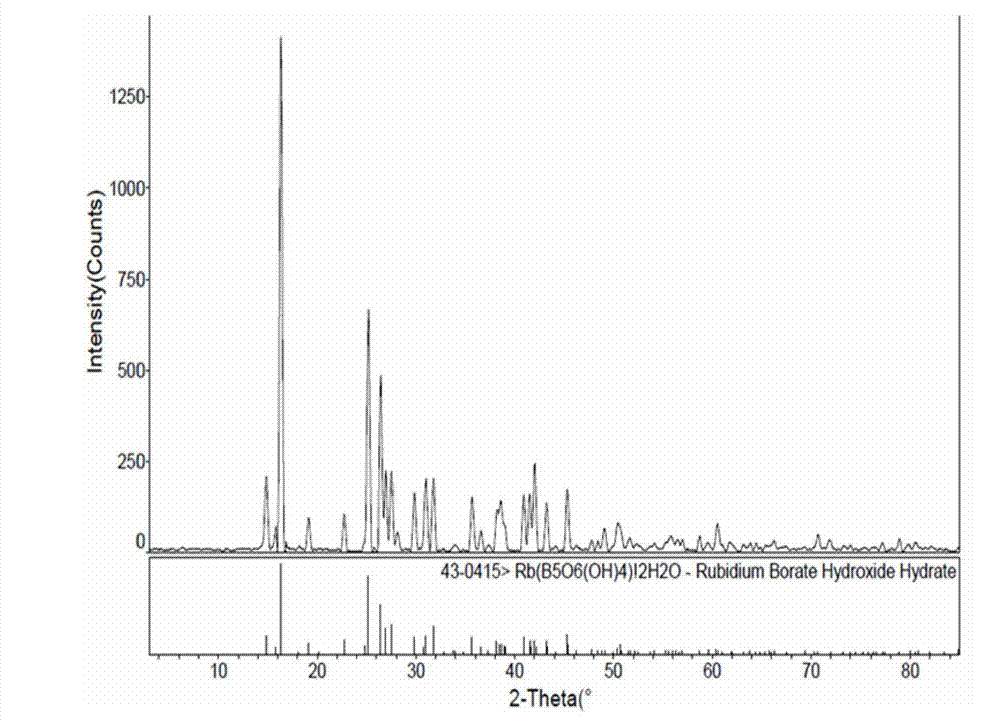

[0030] The reaction formula of boric acid and rubidium carbonate solution in the inventive method is as follows:

[0031] Rb 2 CO 3 +H 3 BO 3 +H 2 O→Rb[B 5 o 6 (OH) 4 ]·2H 2 O+CO 2 ↑+H 2 o

[0032] Among them, rubidium carbonate is very easy to absorb water. In order to increase the yield, as a preferred solution, it needs to be dried before using rubidium carbonate to remove water. As a more preferred solution, rubidium carbonate should be heated at 150-200 ° C before adding the boric acid solution. Dry to constant weight.

[0033] Further, on...

Embodiment 1

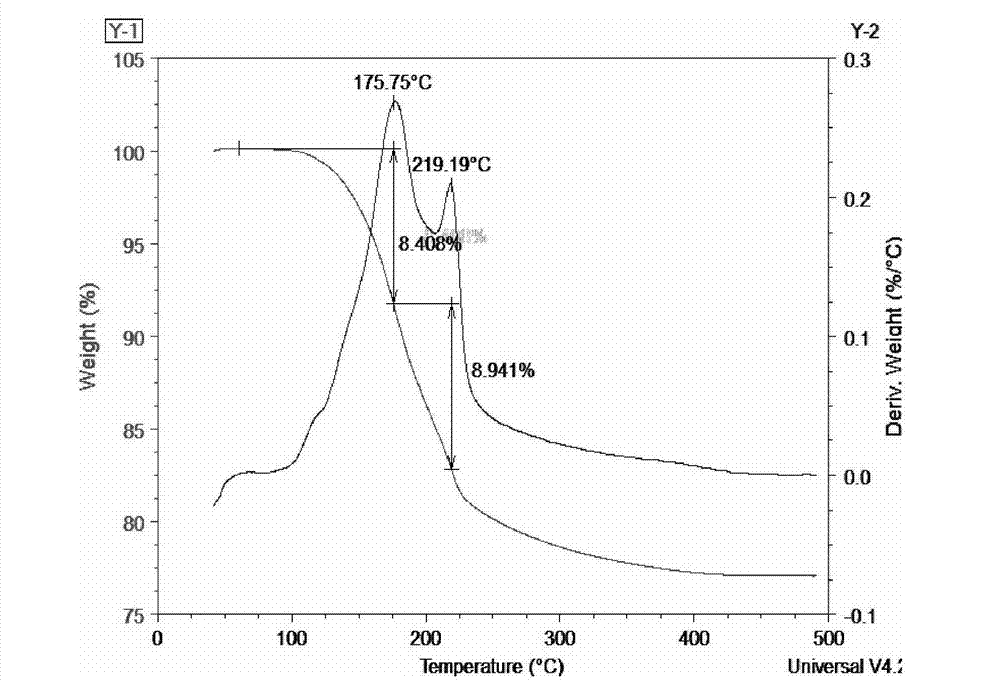

[0041] Embodiment 1 adopts the inventive method to prepare rubidium pentaborate

[0042] a. Add rubidium carbonate to a 20wt% boric acid solution at 70°C and stir to obtain a reaction solution; wherein, rubidium carbonate is dried at 150°C to constant weight before adding the boric acid solution, and the weight of rubidium carbonate is equal to that in the boric acid solution 7.5% of the water weight; the preparation method of the boric acid solution is: dry the boric acid at 70°C to constant weight, then add it into the water with a temperature of 70°C according to the proportion, dissolve it, and prepare it; the reaction temperature of rubidium carbonate and boric acid 70°C;

[0043] b. Filter the reaction solution obtained in step a, and dry the filter cake at 70°C to obtain the product.

[0044] It has been determined that the synthesis time of rubidium pentaborate in this embodiment is 19 hours in total, and the yield of rubidium pentaborate is 98.06%.

Embodiment 2

[0045] Embodiment 2 adopts the inventive method to prepare rubidium pentaborate

[0046] a. Add rubidium carbonate to a 20wt% boric acid solution at 75°C and stir to obtain a reaction solution; wherein, rubidium carbonate is dried at 180°C to constant weight before adding the boric acid solution, and the weight of rubidium carbonate is equal to that in the boric acid solution 7.5% of water weight; the preparation method of boric acid solution is: dry boric acid at 75°C to constant weight, then add it into water with a temperature of 75°C according to the proportion, dissolve it, and prepare it; the reaction temperature of rubidium carbonate and boric acid 75°C;

[0047] b. Filter the reaction solution obtained in step a, and dry the filter cake at 75°C to obtain the product.

[0048] It has been determined that the synthesis time of rubidium pentaborate in this embodiment is 18 hours in total, and the yield of rubidium pentaborate is 98.85%.

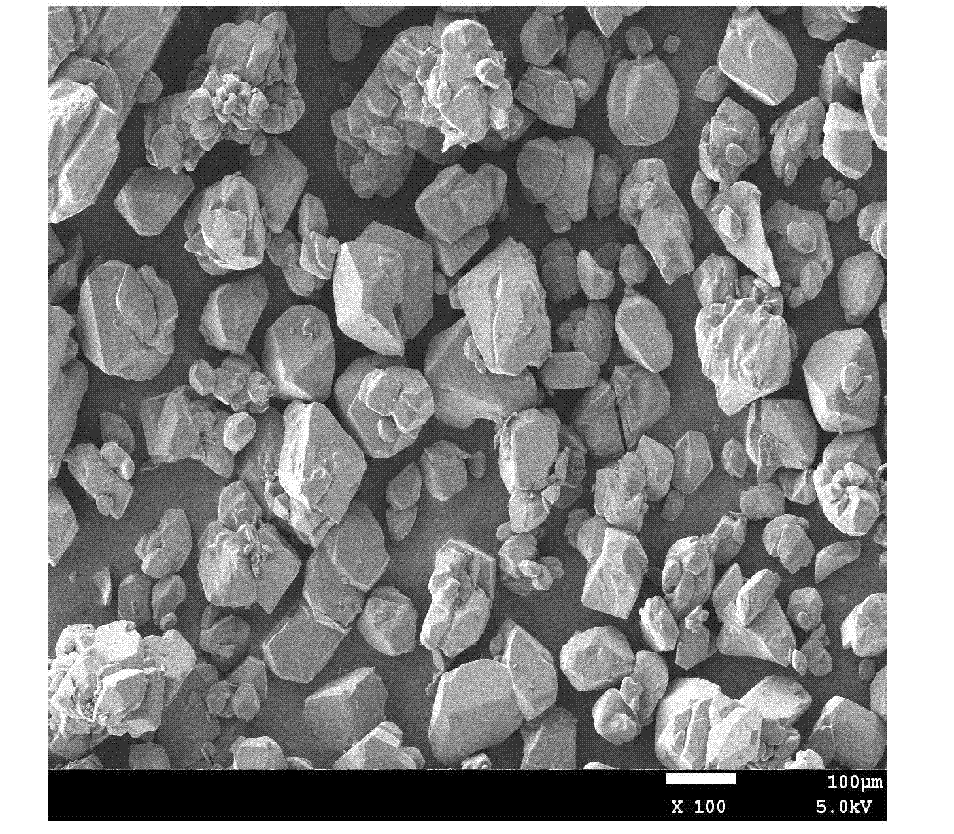

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com