Preparation method of high-purity anhydrous rubidium iodide

A technology of rubidium iodide and iodide, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of difficulty in large-scale production, high raw material cost and energy consumption, harsh process conditions, etc. Stable, easy to operate, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

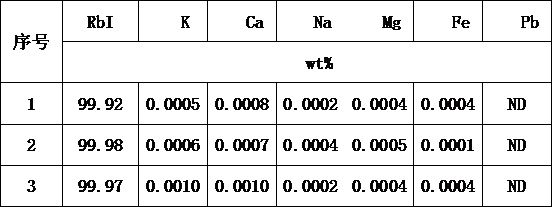

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of high-purity anhydrous rubidium iodide, it is characterized in that, comprises the following steps:

[0029] Step A Dissolution of rubidium carbonate: at room temperature, take 400-600g of rubidium carbonate and put it into a reaction vessel, slowly add pure water with a mass-liquid-solid ratio of 2-4:1 while stirring, stir for 10-30min, wait for carbonation Rubidium is completely dissolved;

[0030] Step B Filtration and impurity removal: At room temperature, filter the solution obtained in step A while it is hot, and use a 1-5um sand core funnel for filtration to remove alkaline insolubles and other impurities to obtain a clear and transparent rubidium carbonate solution;

[0031] Step C disproportionation reaction: at normal temperature, slowly pour into the rubidium carbonate solution obtained in step B under stirring conditions the iodine element whose molar ratio Li:I is 1:1 to carry out disproportionation reac...

Embodiment 1

[0049] step a. Dissolution of rubidium carbonate: At room temperature, put 400g of rubidium carbonate into the reaction vessel, slowly add 800g of pure water while stirring, stir for 10min, and wait until the rubidium carbonate is completely dissolved.

[0050] Step B. Filtration to remove impurities: At room temperature, filter the solution obtained in the above step A while it is hot, and use a 3um sand core funnel for filtration to remove alkaline insolubles and other impurities to obtain a clear and transparent rubidium carbonate solution.

[0051] Step C. Disproportionation reaction: at normal temperature, slowly pour into the rubidium carbonate solution obtained in step B under stirring conditions, the molar ratio Rb:I is 1:1 iodine simple substance 439.6g to carry out disproportionation reaction, after stirring for 15min, the reaction generates dark brown solution .

[0052] Step D. Hydrazine hydrate reduction reaction: at room temperature, slowly add 54.2 g of hydr...

Embodiment 2

[0059] step a. Dissolution of rubidium carbonate: At room temperature, put 500g of rubidium carbonate into the reaction vessel, slowly add 1500g of pure water while stirring, stir for 20min, and wait until the rubidium carbonate is completely dissolved.

[0060] Step B. Filtration and removal of impurities: at room temperature, filter the solution obtained in the above step A while it is hot, and use a 4um sand core funnel for filtration to remove alkaline insolubles and other impurities to obtain a clear and transparent rubidium carbonate solution.

[0061] Step C. Disproportionation reaction: at normal temperature, slowly pour into the rubidium carbonate solution obtained in step B under stirring conditions, the molar ratio Rb:I is 1:1 iodine simple substance 549.5g to carry out disproportionation reaction, after stirring for 18min, the reaction generates a dark brown solution .

[0062] Step D. Hydrazine hydrate reduction reaction: at room temperature, slowly add 68.5 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com