Manufacture technique of burley characteristic reconstituted tobacco

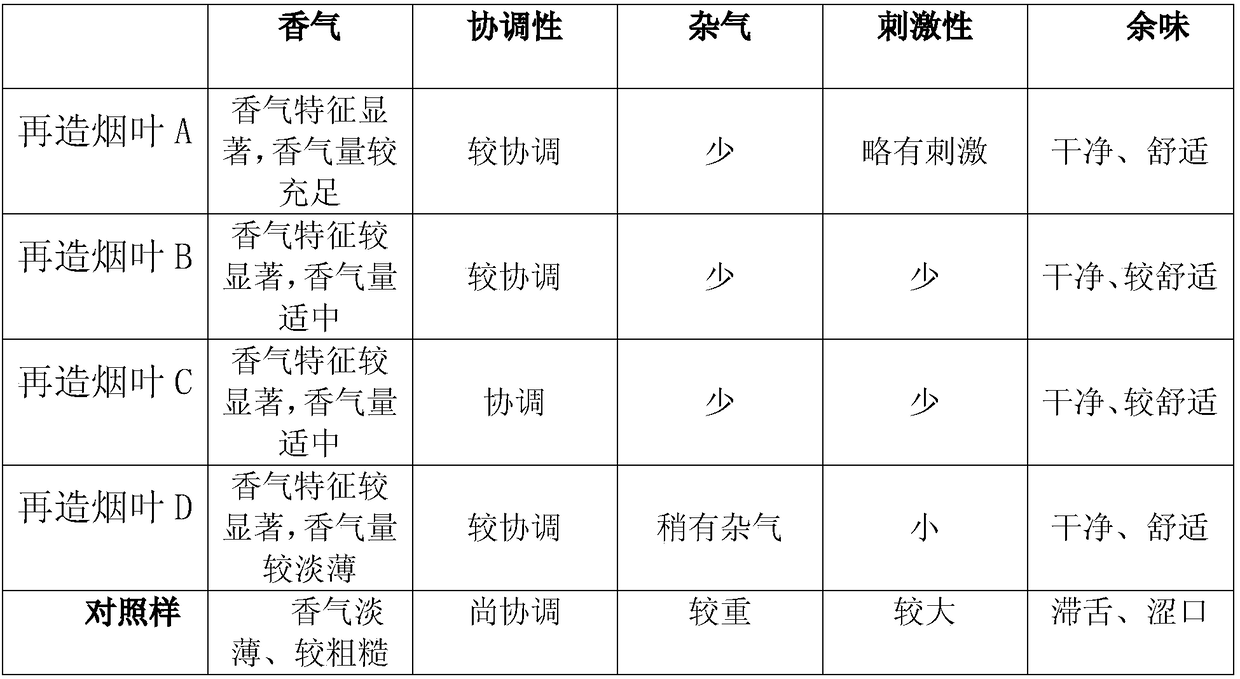

A technology of reconstituted tobacco leaves and manufacturing process, which is applied in the field of manufacturing process of Burley characteristic reconstituted tobacco leaves, which can solve the problems of complicated process, high cost, and excessive additives, and achieve the effects of improving aroma characteristics, low cost, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the described manufacturing process of reconstituted tobacco leaves with Burley characteristics is characterized in that the specific steps are as follows:

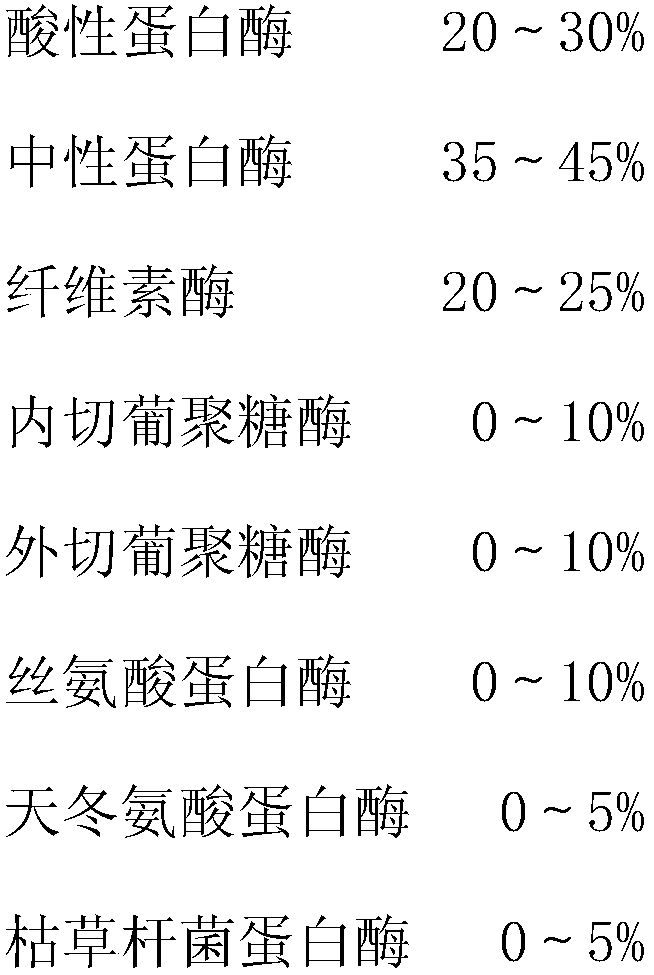

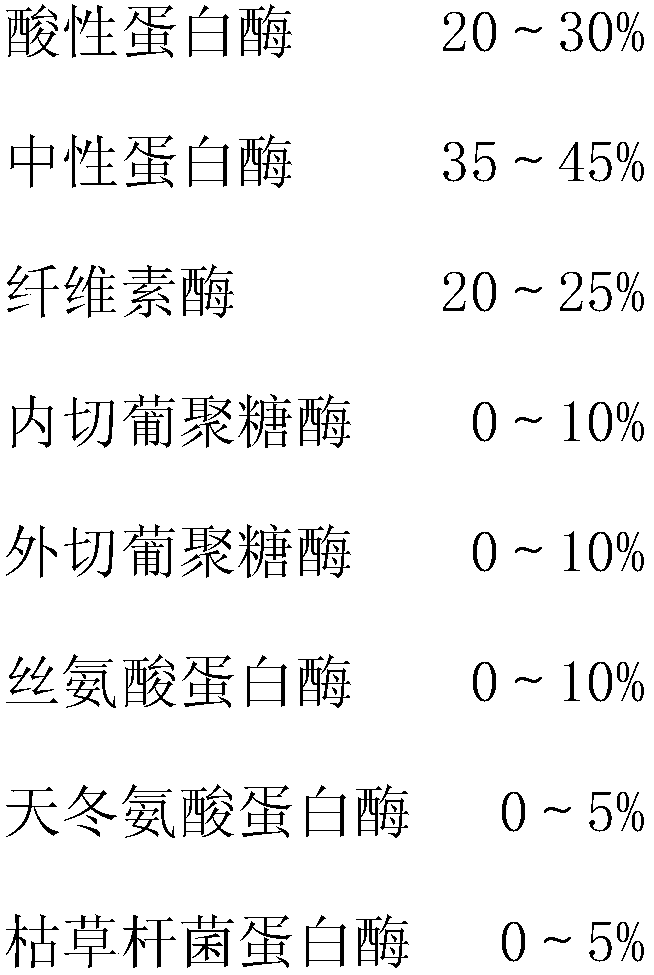

[0034] (1) Compound enzyme is prepared according to the following mass percentages: 30% acid protease, 45% neutral protease, 25% cellulase;

[0035](2) 1000kg burley tobacco leaf material is added in the final material extraction tank, and the compound enzyme in the step (1) of 0.6% of burley tobacco leaf material weight percent is added simultaneously, then add the water of 5 times of burley tobacco leaf material weight, in At a temperature of 55°C, extract for 40 minutes in a two-step countercurrent manner, and separate the extracted solid-liquid mixture through a horizontal screw centrifuge to obtain leaf solid matter and leaf extract;

[0036] (3) Put 500kg of Burley tobacco stem material into the stem material extraction tank, add water 4 times its weight, and extract for 20 minutes in a two-step...

Embodiment 2

[0043] Embodiment 2, described a kind of manufacturing process with Burley characteristic reconstituted tobacco leaf, is characterized in that concrete steps are as follows:

[0044] (1) Compound enzyme is prepared according to the following mass percentages: acid protease 20%, neutral protease 35%, cellulase 20%, endoglucanase 5%, exoglucanase 6%, serine protease 7% , aspartic protease 3%, subtilisin 4%;

[0045] (2) Add 1000kg of tobacco powder raw materials into the final material extraction tank, add 0.65% of the compound enzyme in step (1) at the same time, then add 5000kg of water at a temperature of 55°C, and extract according to the two-step countercurrent method. The time is controlled at 40 minutes, and the extracted solid-liquid mixture is separated by a horizontal screw centrifuge to obtain solid substances and extracts;

[0046] (3) Add 540 kg of tobacco stem raw materials into the stem material extraction tank, then add 2160 kg of water at a temperature of 75° C...

Embodiment 3

[0053] Embodiment 3, described a kind of manufacturing process with Burley characteristic reconstituted tobacco leaf, is characterized in that concrete steps are as follows:

[0054] (1) Compound enzyme is formulated according to the following mass percentages: 25% acid protease, 35% neutral protease, 20% cellulase, 3% endoglucanase, 7% exoglucanase, serine Protease 5%, aspartic protease 2%, subtilisin 3%;

[0055] (2) 1000kg burley tobacco leaf material is added in the final material extraction tank, and compound enzyme is added in the step (1) of 0.55% of burley tobacco leaf material weight percent simultaneously, then add the water of 5 times of burley tobacco leaf material weight, in At a temperature of 55°C, extract for 40 minutes in a two-step countercurrent manner, and separate the extracted solid-liquid mixture through a horizontal screw centrifuge to obtain leaf solid matter and leaf extract;

[0056] (3) Put 500kg of Burley tobacco stem material into the stem materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Baume degrees | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com