Oily lithium battery membrane coating treatment method and device

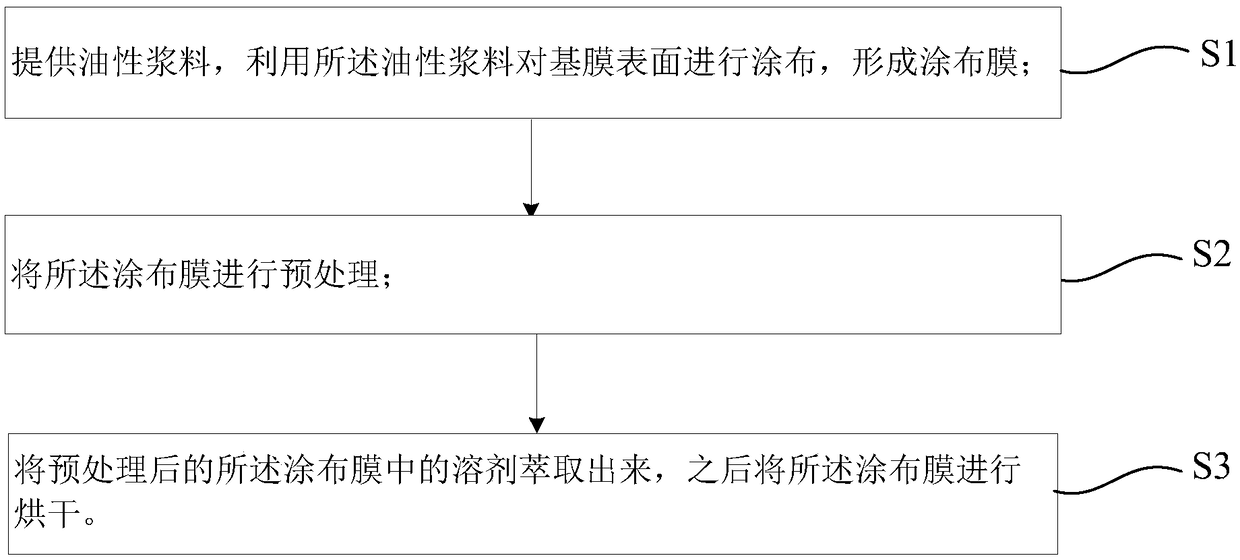

A technology for lithium battery separators and treatment methods, which is applied in the direction of surface coating liquid devices, pretreatment surfaces, coatings, etc., which can solve problems such as unclean solvent extraction, internal defects, and uneven coatings, and achieve the elimination of internal Effects of defects, performance enhancement, good breathability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

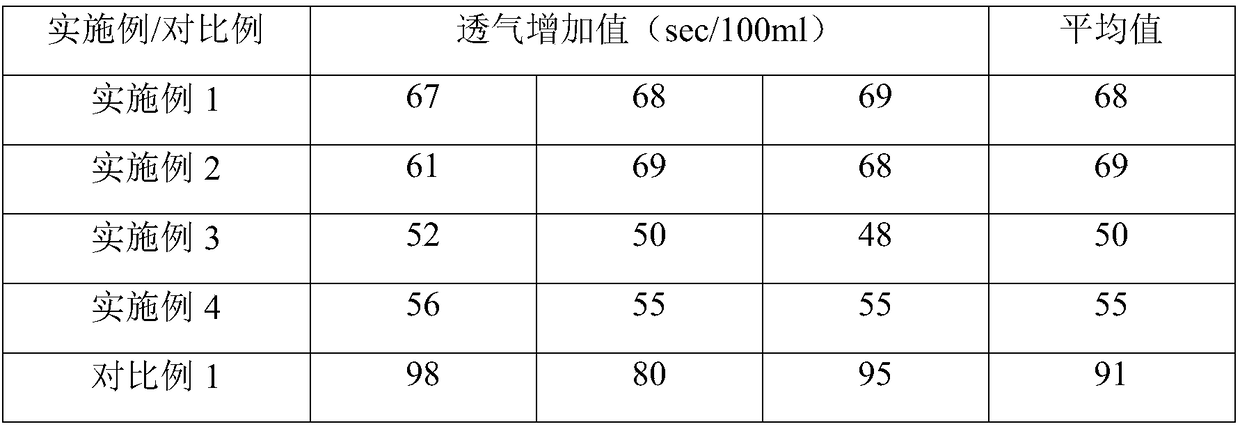

[0053] After the oily slurry lithium battery diaphragm is coated, it passes through a constant temperature and humidity box, the temperature of the constant temperature and humidity box is 40°C, and the relative humidity is 60%, and then it is washed with water in a water tank, and then dried to obtain an oily coating film.

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that the conditions of the constant temperature and humidity chamber in this embodiment are: the temperature is 40° C., the relative humidity is 70%, and other operations are the same as in Embodiment 1. An oily coating film can be obtained.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that the conditions of the constant temperature and humidity chamber in this embodiment are: the temperature is 50° C., the relative humidity is 60%, and other operations are the same as in Embodiment 1. An oily coating film can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com