Axial-piston machine of the swashplate or oblique-axis type of construction

a technology of axial piston machine and oblique axis, which is applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of leakage flow through the microgroove and remain very low, and achieve the effect of further structural free space and small reverse notches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

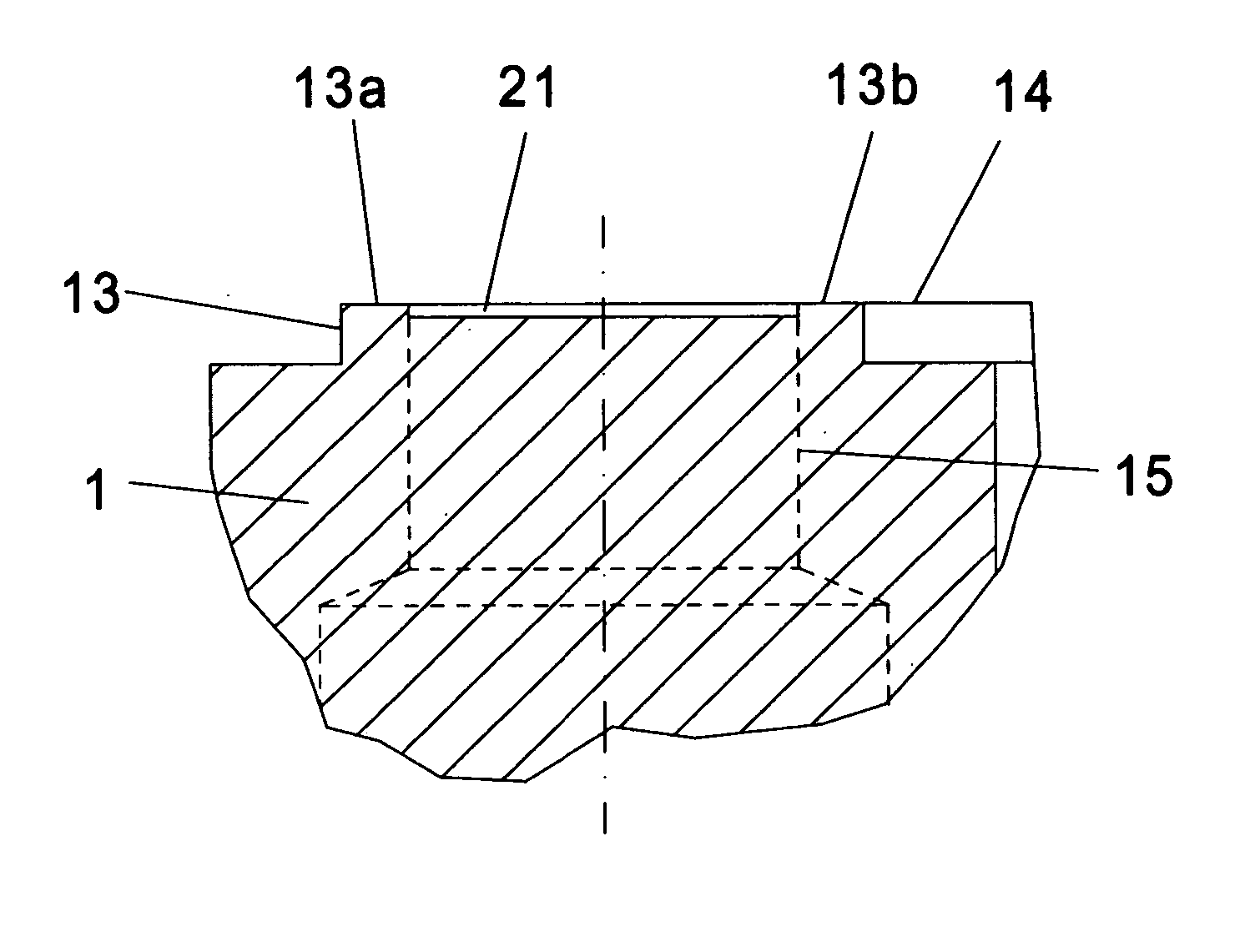

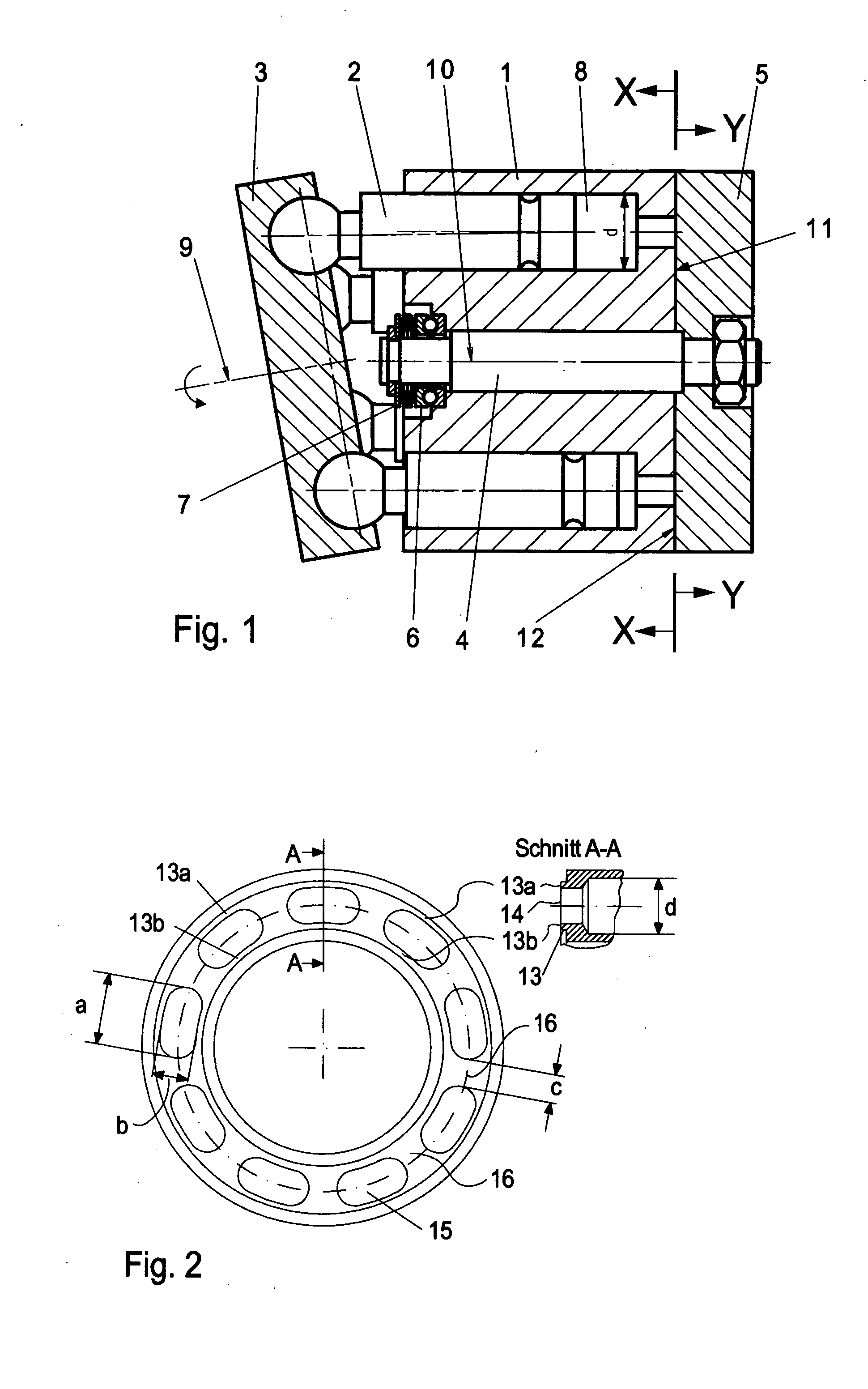

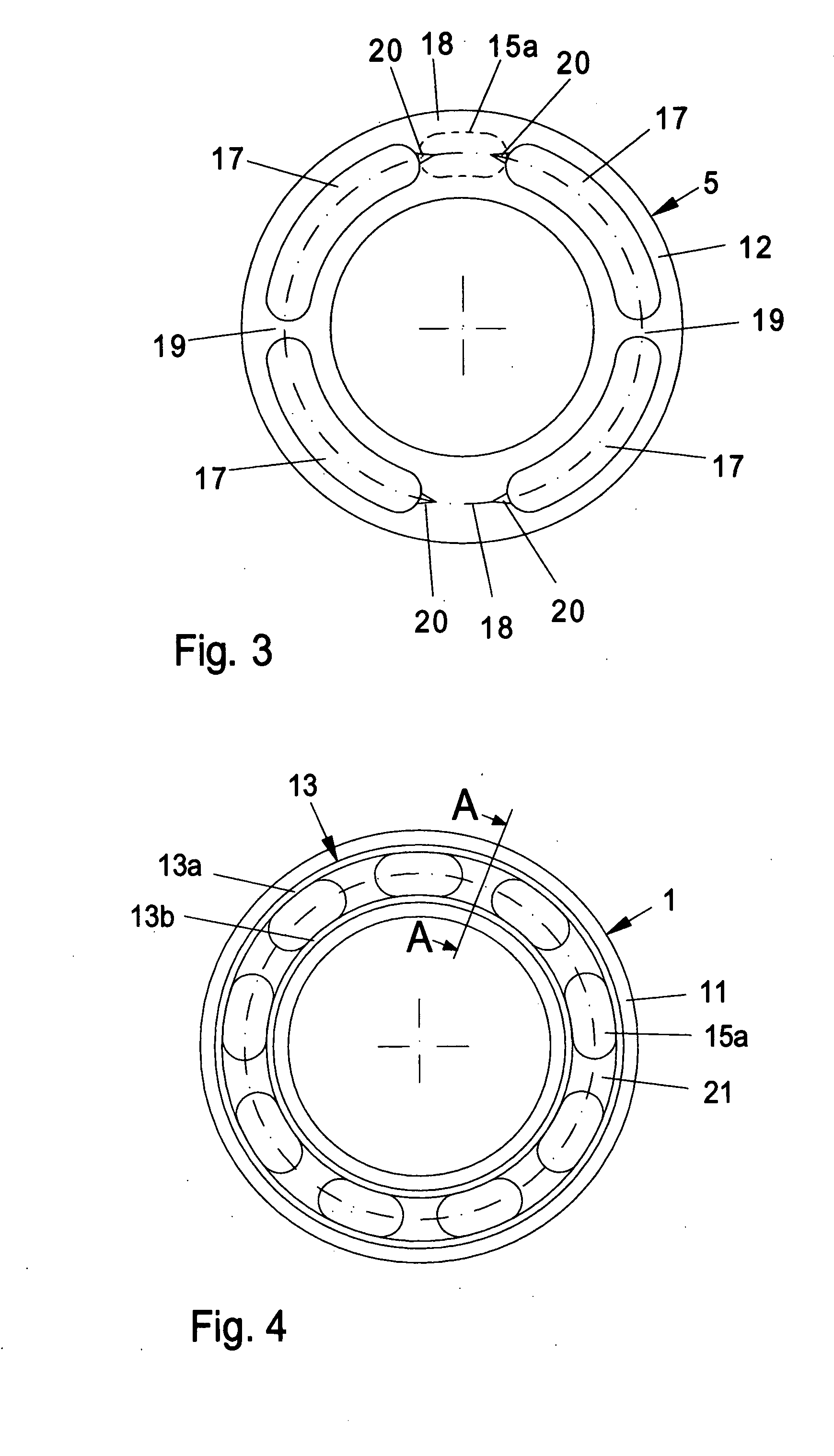

[0022] FIGS. 1 to 3 show the design of an axial-piston machine according to the prior art. About a central journal 4 rotates a cylinder block 1 which is provided with displacer spaces 8 running axially. In the example illustrated, there are nine displacer spaces 8, cf. FIG. 2. In the displacer spaces 8 slide the pistons 2 which are acted upon axially by the rotating drive flange 3. The axis of rotation 9 of the drive flange 3 runs obliquely to the axis of rotation 10 of the cylinder block 1. The pistons 2 thereby execute a lifting movement with the action of sucking in and expelling hydraulic fluid.

[0023] 5 designates a valve plate, through which the hydraulic fluid is supplied to the displacer spaces 8 of the cylinder block 1 and discharged. The cylinder block 1 is prestressed axially against the valve plate 5 by means of a pressure spring 7 arranged on the axial bearing 6 of the said cylinder block. In this case, the end face 11 of the cylinder block 1 bears at least with a conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com