45 deg. oblique axis pumping method and pumping module for strip shaped laser crystal

A laser crystal and strip technology, applied in the laser field, can solve the problems of high cost, complicated process, and the pump light and the laser output optical axis are not parallel, so as to reduce the interface reflection loss, improve the efficiency, and improve the pump power density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

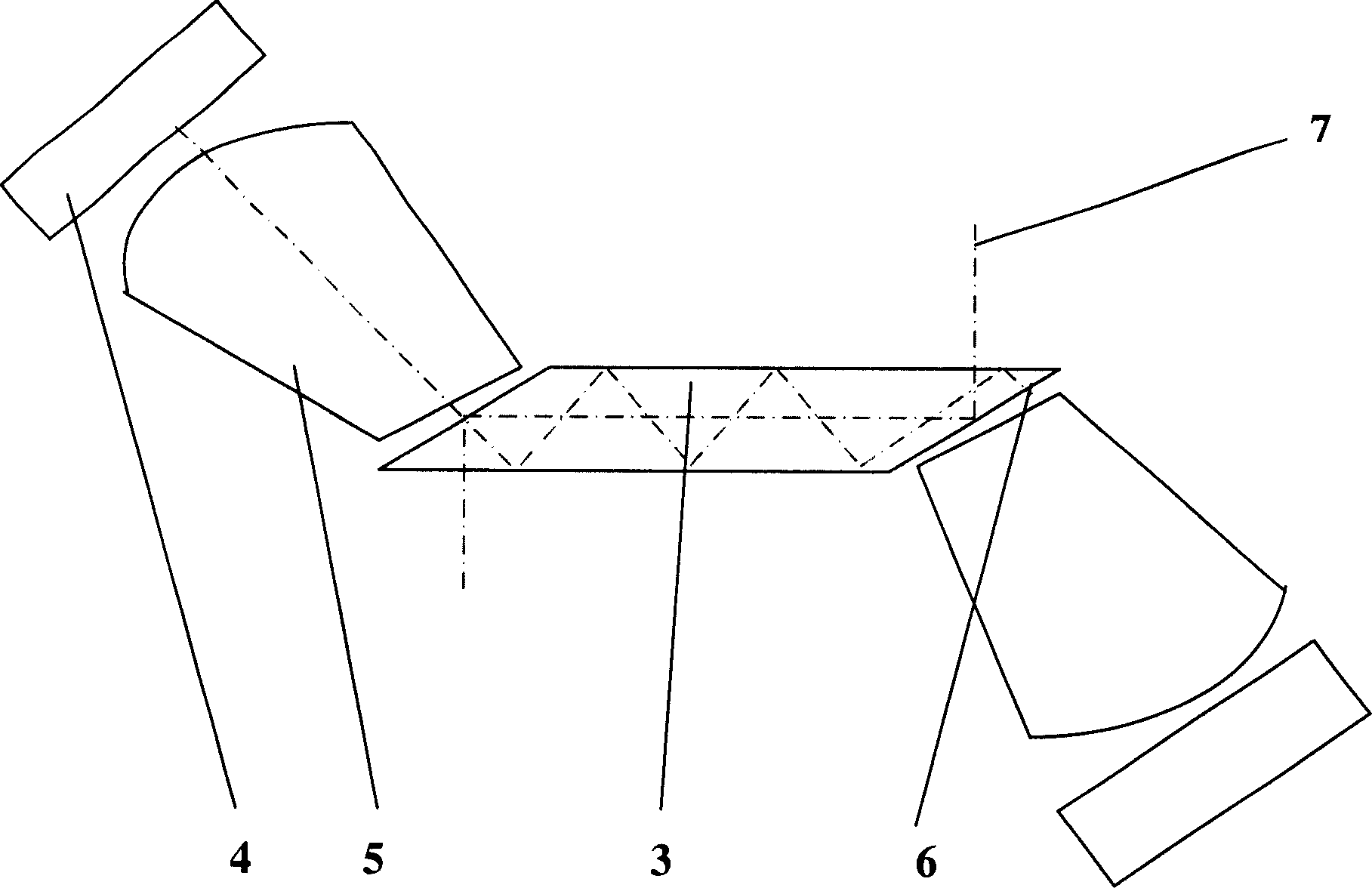

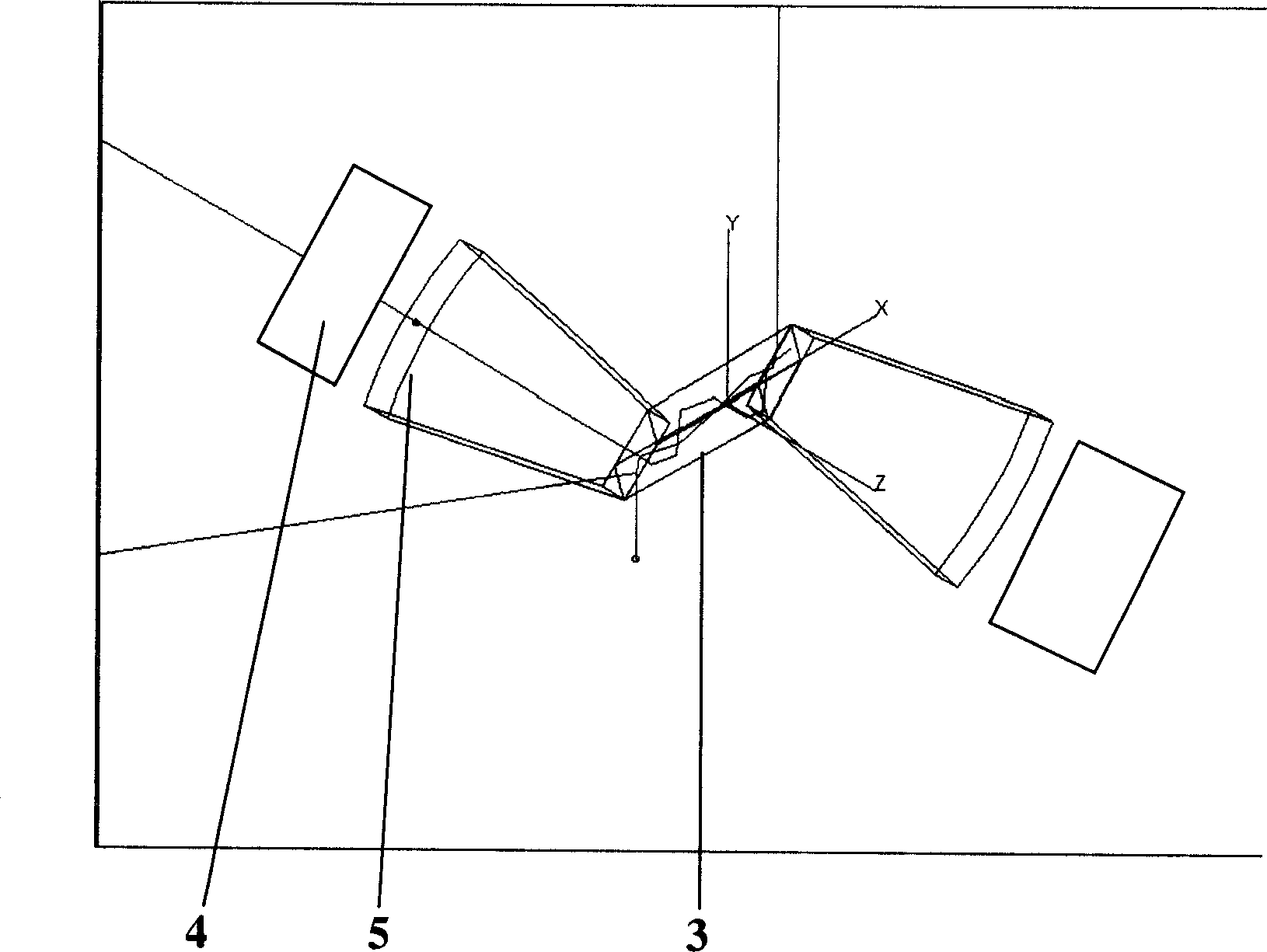

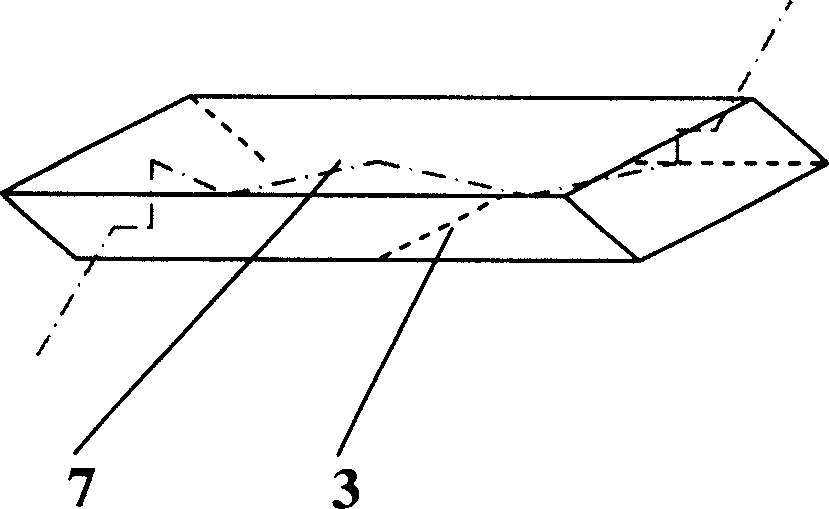

[0019] The invention provides a 45° oblique-axis pumping method for a slab-shaped laser crystal, that is, the end of the slab-shaped laser crystal is processed into a 45° inclined plane with the longitudinal direction of the laser crystal, so that the pumping light passes through the The 45° slope is coupled into the laser crystal, and the pump light propagates in the laser crystal in a zig-zag (Zig-Zag) manner to pump the laser crystal; in the plane of the pump optical axis, the pump optical axis and the vibration incident from the side / Amplify the projection of the laser optical axis into a 45° angle.

[0020] In the above method, one input method of oscillating / amplifying laser is: vertically cutting the other two sides of the slab-shaped laser crystal, so that the oscillating / amplifying laser is injected into the vertical plane, and passes through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com