Connecting joint of fabricated steel structure and prefabricated externally-hung wall panel with damping performance

A technology for externally hanging wallboards and shock-absorbing performance, which is applied to walls, shockproof, building components, etc., and can solve problems such as wallboard damage and flexible connections that cannot be effectively used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

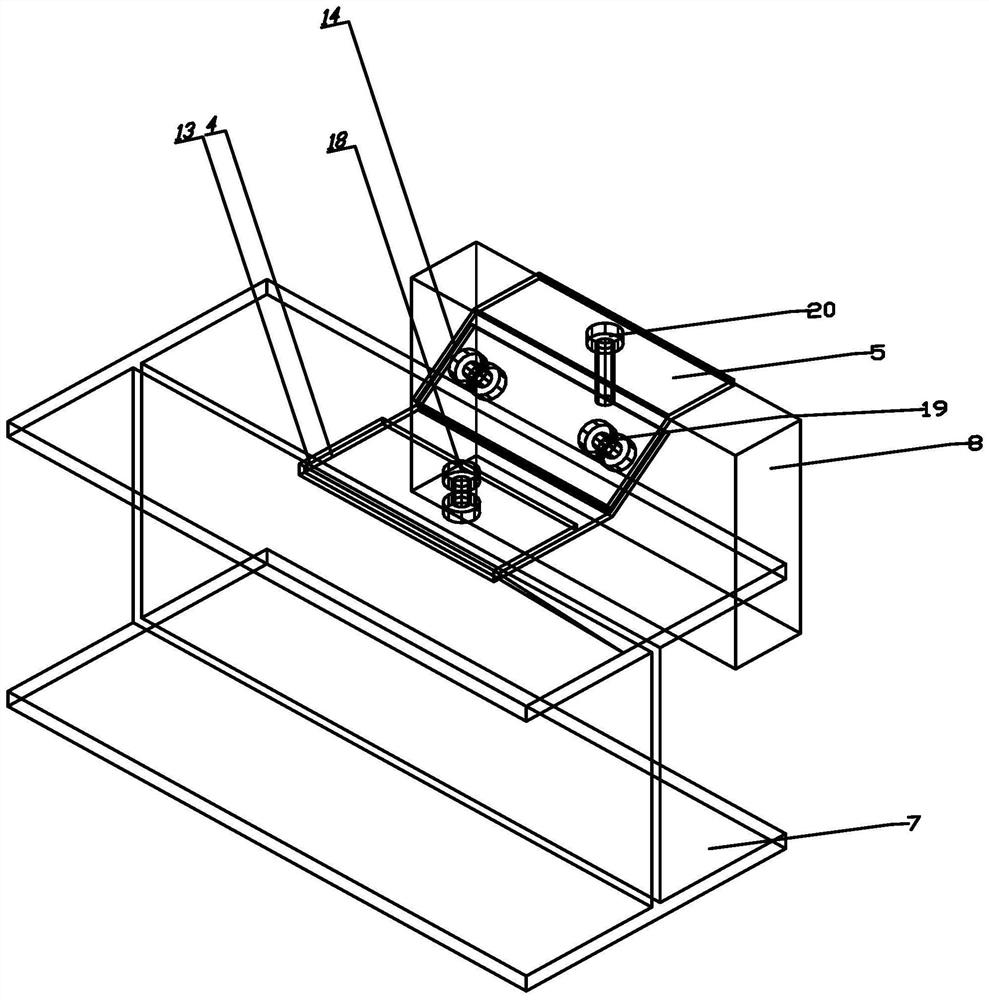

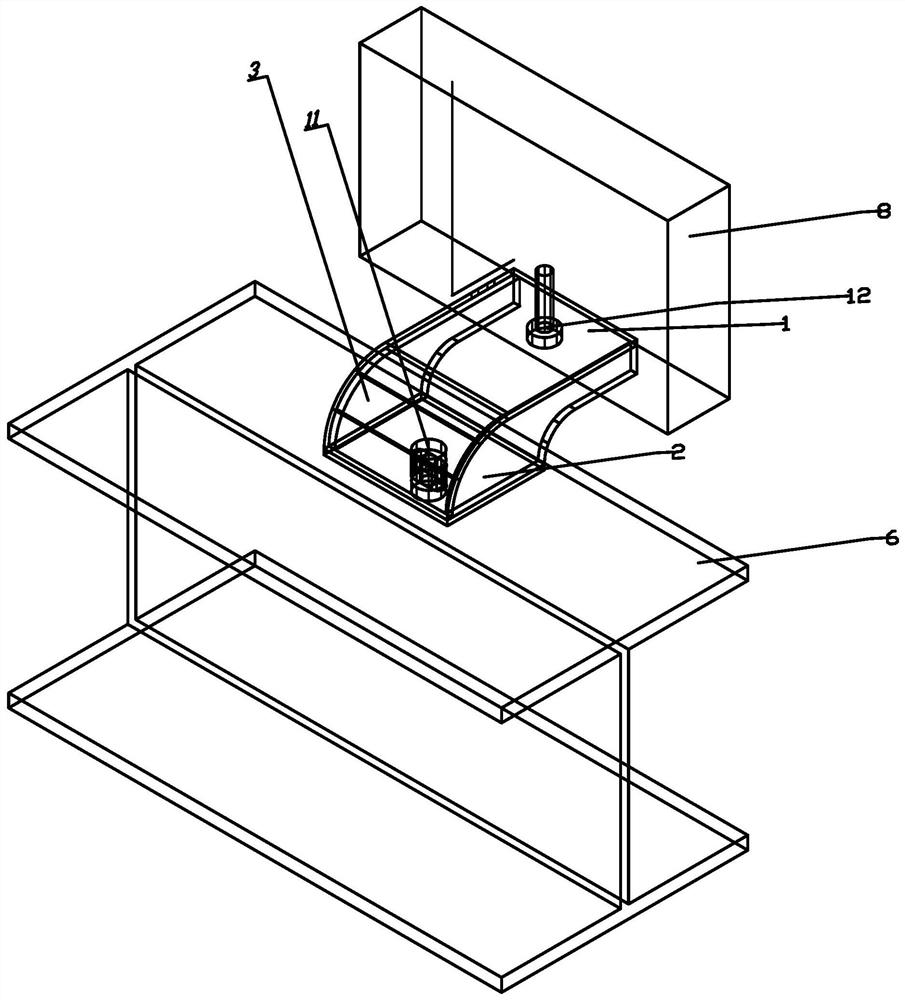

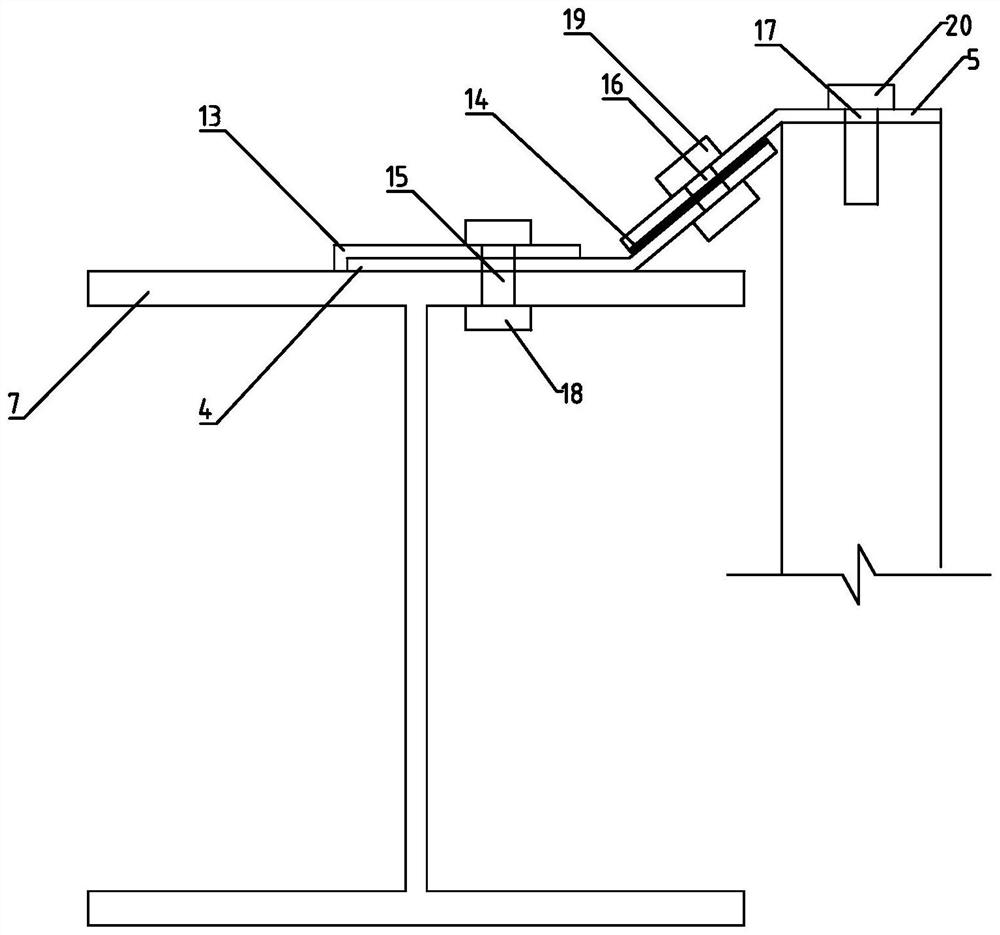

[0028] Such as figure 1 and figure 2 As shown, the connection node between the assembled steel structure with shock absorption performance and the prefabricated external wall panel includes the lower frame beam 6, the upper frame beam 7 and the external wall panel 8, and the lower frame beam 6 is connected to the external wall panel through the lower node connector. The wallboard 8 is connected, and the upper frame beam 7 is connected with the external wallboard 8 through the upper node connector; the gap between the top of the external wallboard 8 and the frame beam can be filled with thermal insulation material.

[0029] Such as figure 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com