Sintered ore containing specular hematite and preparation method of sintered ore

A technology for specularite and sintered ore, which is applied in the field of sintered ores containing specularite and its preparation, can solve the problems of poor hydrophilicity and poor reactivity of specularite, and achieves high cohesive crystal strength, improved utilization rate, and full utilization of specularite. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

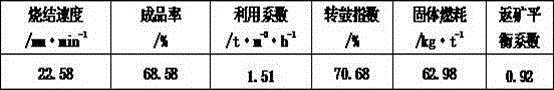

[0015] Example 1

[0016] A sintered ore containing specularite, its raw material composition and weight percentage content are: specularite with particle size ≤ 1mm: 55%, returned ore with particle size ≤ 5mm: 32%, fuel with particle size ≤ 4mm: 3.7%, particle size Flux ≤ 4mm: 9.3%, plus 4.5% of the total weight of the above raw materials of quicklime with an activity of 250.

[0017] Preparation steps:

[0018] 1) First mix 55% specularite with particle size ≤ 1mm and 4.5% quicklime with activity degree 250, then add water according to 6% of the total amount of the mixture and stir evenly;

[0019] 2) Put the mixed slurry material into the disc machine for granulation; the disc machine granulation time is 6 minutes; after testing, its strength reaches 1.5N / / cm 2 ,stand-by;

[0020] 3) First mix 32% of the returned ore with a particle size of ≤5mm, 3.7% of the fuel with a particle size of ≤4mm, and 9.3% of the flux with a particle size of ≤4mm; then mix with the p...

Example Embodiment

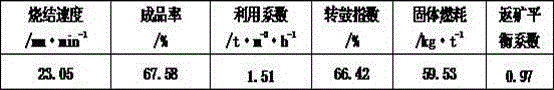

[0023] Example 2

[0024] A sintered ore containing specularite, its raw material composition and weight percentage content are: specularite with particle size ≤ 1mm: 60%, returned ore with particle size ≤ 5mm: 28%, fuel with particle size ≤ 4mm: 4%, particle size Flux ≤ 4mm: 8%, plus 1.2% organic bentonite based on the total weight of the above raw materials.

[0025] Preparation steps:

[0026] 1) First mix 60% specularite with particle size ≤ 1mm and 1.2% organic bentonite, then add water according to 7% of the total amount of the mixture and stir evenly;

[0027] 2) Put the mixed slurry material into the disc machine for granulation; the disc machine granulation time is 8 minutes; after testing, its strength reaches 1.2N / / cm 2 ,stand-by;

[0028] 3) First mix 28% of the returned ore with a particle size of ≤5mm, 4% of the fuel with a particle size of ≤4mm, and 8% of the flux with a particle size of ≤4mm; then mix with the prepared specularite particles; and sin...

Example Embodiment

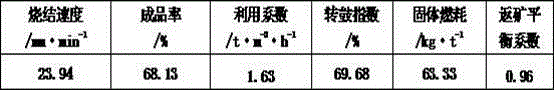

[0031] Example 3

[0032] A sintered ore containing specularite, its raw material composition and weight percentage content are: specularite with particle size ≤ 1mm: 45%, returned ore with particle size ≤ 5mm: 21%, fuel with particle size ≤ 4mm: 3.5%, particle size Flux ≤ 4mm: 9.5%, other iron ore with particle size ≤ 10mm 21%, plus 2% organic bentonite based on the total weight of the above raw materials.

[0033] Preparation steps:

[0034] 1) First mix 45% specularite with particle size ≤ 1mm and 2% organic bentonite, then add water according to 8% of the total amount of the mixture and stir evenly;

[0035] 2) Put the mixed slurry material into the disc machine for granulation; the disc machine granulation time is 12 minutes; after testing, its strength reaches 1.1N / / cm 2 ,stand-by;

[0036] 3) Mix 21% of returned ore with a particle size of ≤5mm, 3.5% of fuel with a particle size of ≤4mm, 9.5% of flux with a particle size of ≤4mm, and 21% of other iron ores w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com