Steel-bamboo composite elevator structure

A technology of steel bamboo and elevators, which is applied to building components, building structures, vertical pipes, etc., can solve the problems of increasing the load of the main structure, the difficulty of precise positioning of components, and the large amount of steel used, so as to reduce the weight of the building and protect The effect of the construction site environment and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

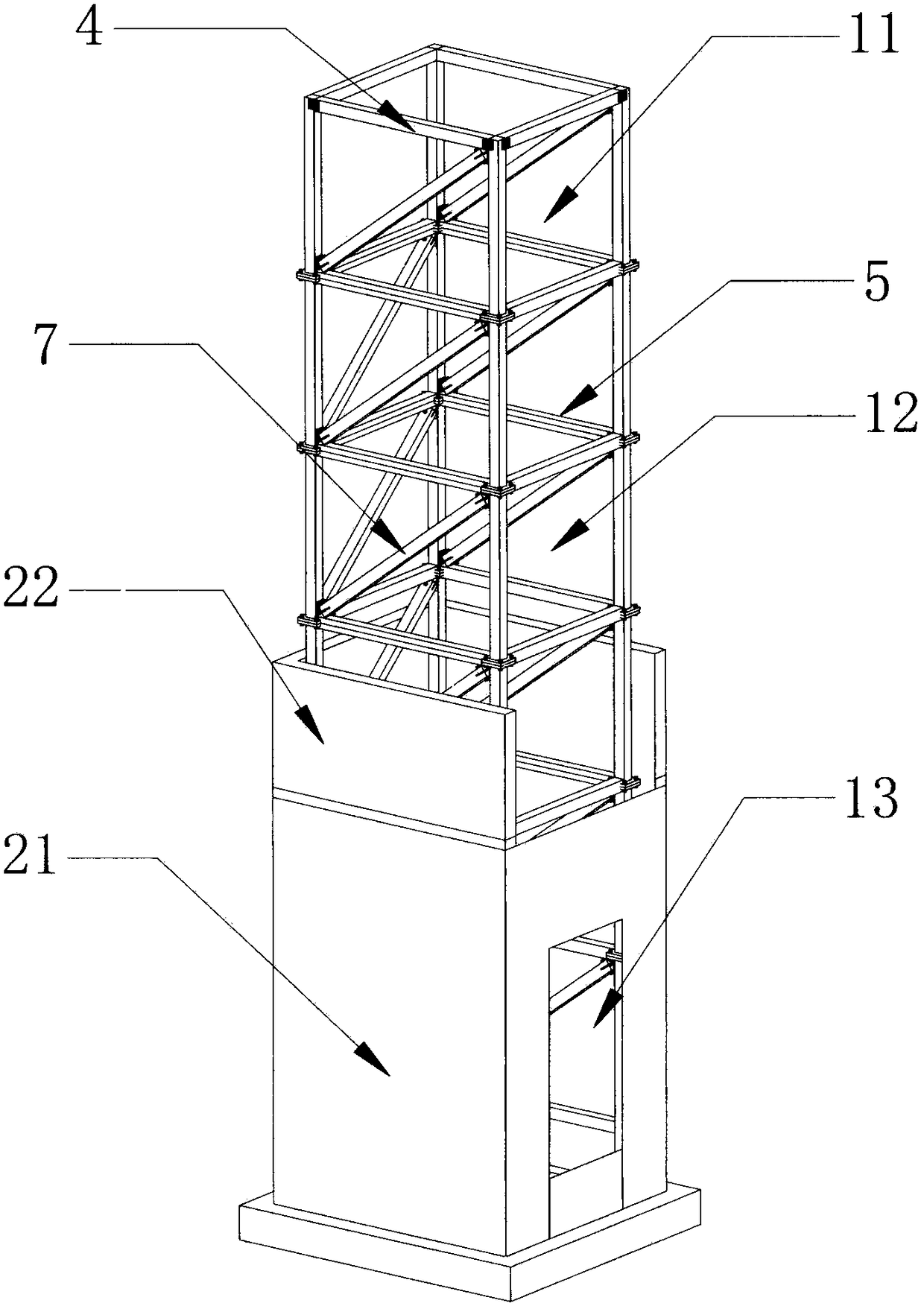

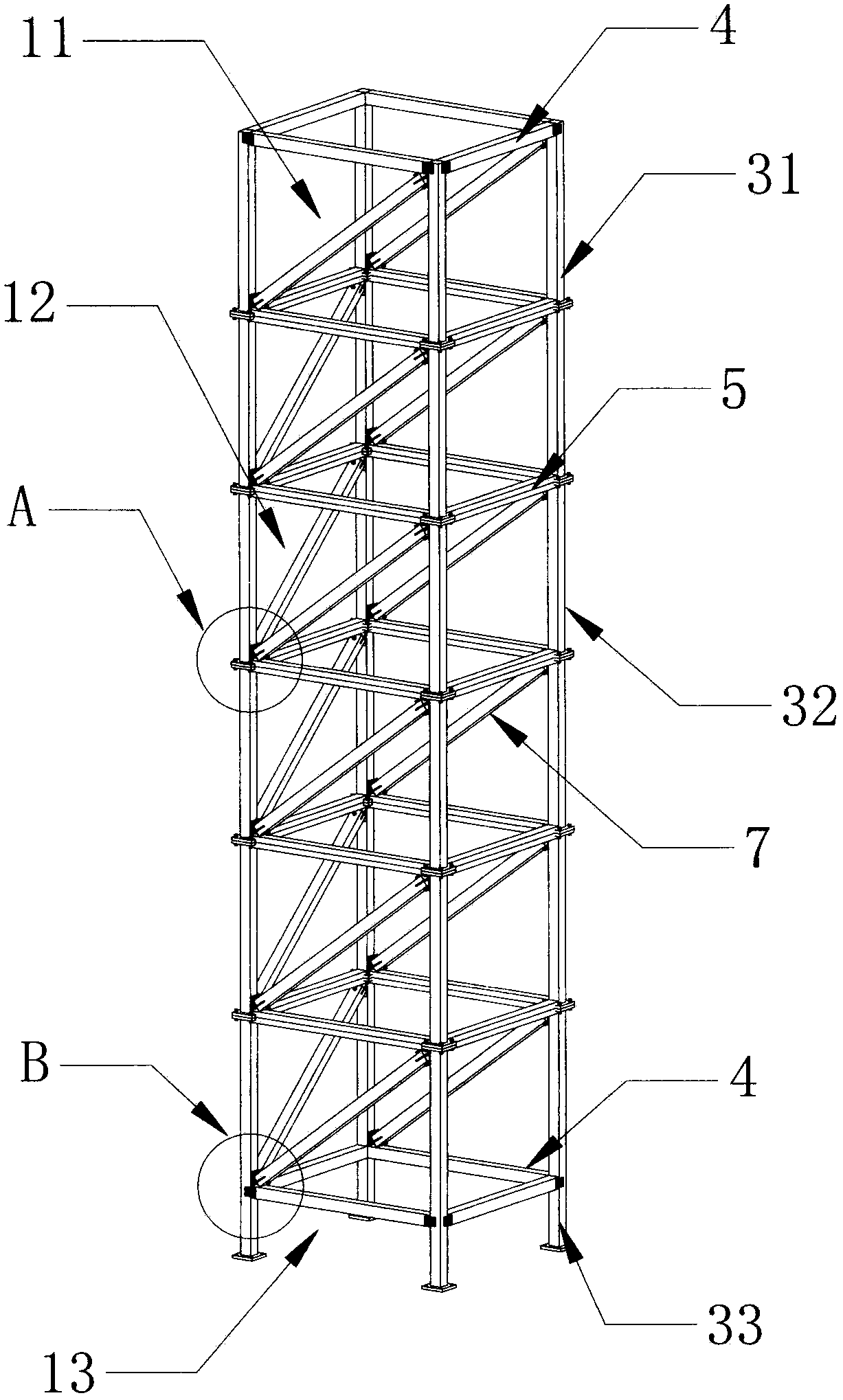

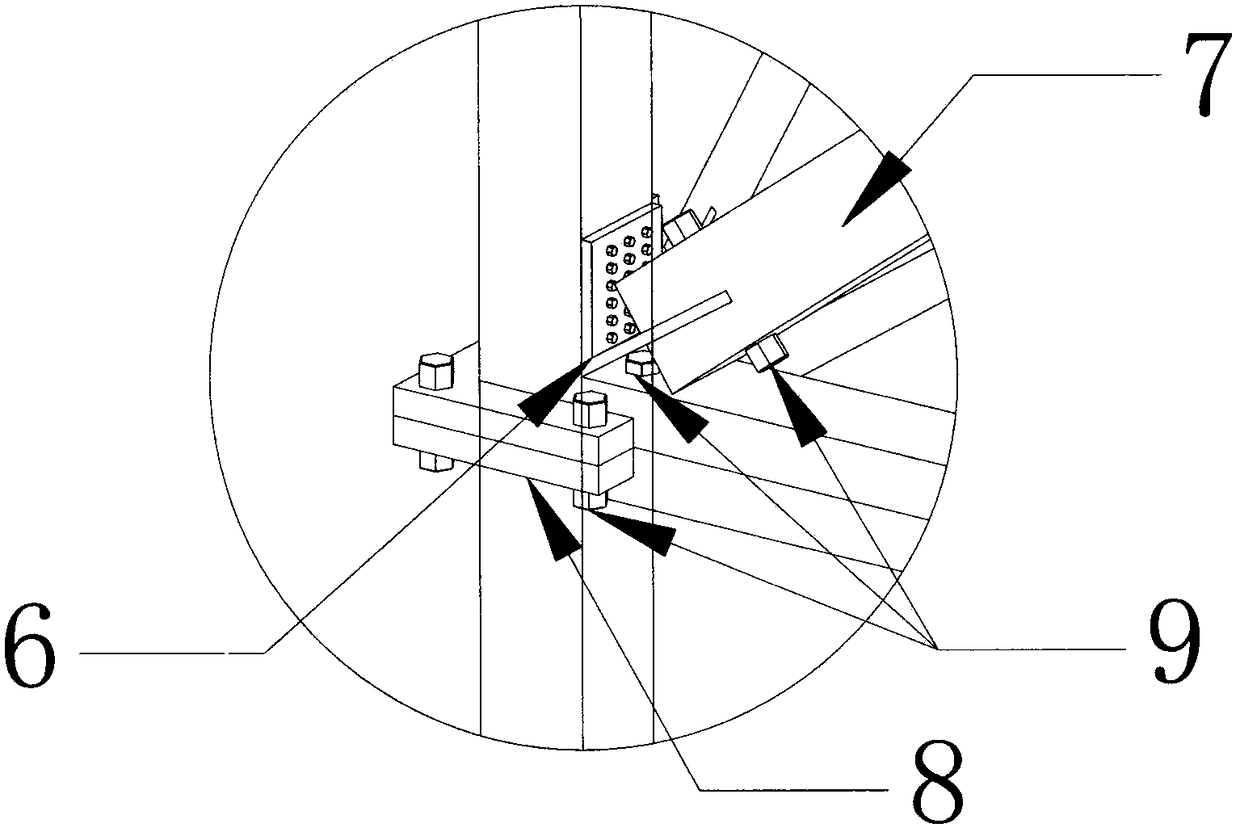

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The present invention provides a steel-bamboo composite elevator structure, comprising a main structure 1 and an enclosure structure 2, characterized in that the main structure 1 consists of a top steel-bamboo composite truss unit 11, a middle steel-bamboo composite truss unit 12 and a bottom steel-bamboo composite truss unit. Composite truss units 13 are spliced up and down, assembled into a system of 3-sided truss and 1-sided frame, 1-sided frame faces the building use side, and the enclosure structure 2 is composed of the base 21 on which the main structure 1 is installed and the ALC lightweight concrete partition wall 22. stitched together.

[0029] The top steel-bamboo composite truss unit 11 includes four top steel columns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com