SCS (structure cabling system) encased structure based on PBL (planetary boundary layer) stiffening ribs

A technology of steel tube concrete and concrete structures, which is applied in the direction of load-bearing elongated structural members, structural elements, building components, etc. It can solve the problems of poor connection performance, self-heavy weight, and small hoop effect, and achieve torsional performance Good, simple form, enhance the effect of the ferrule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

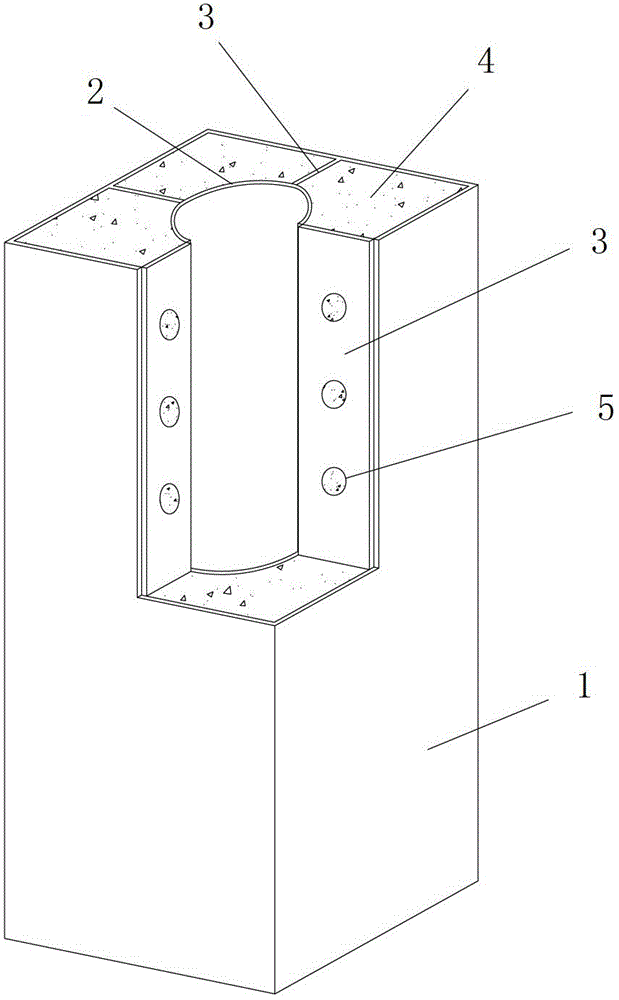

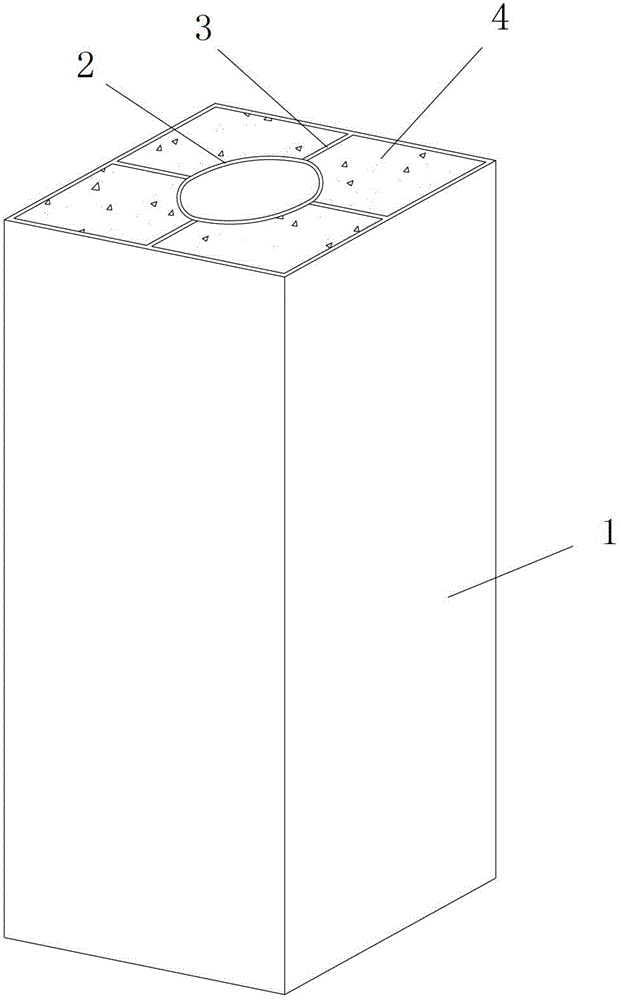

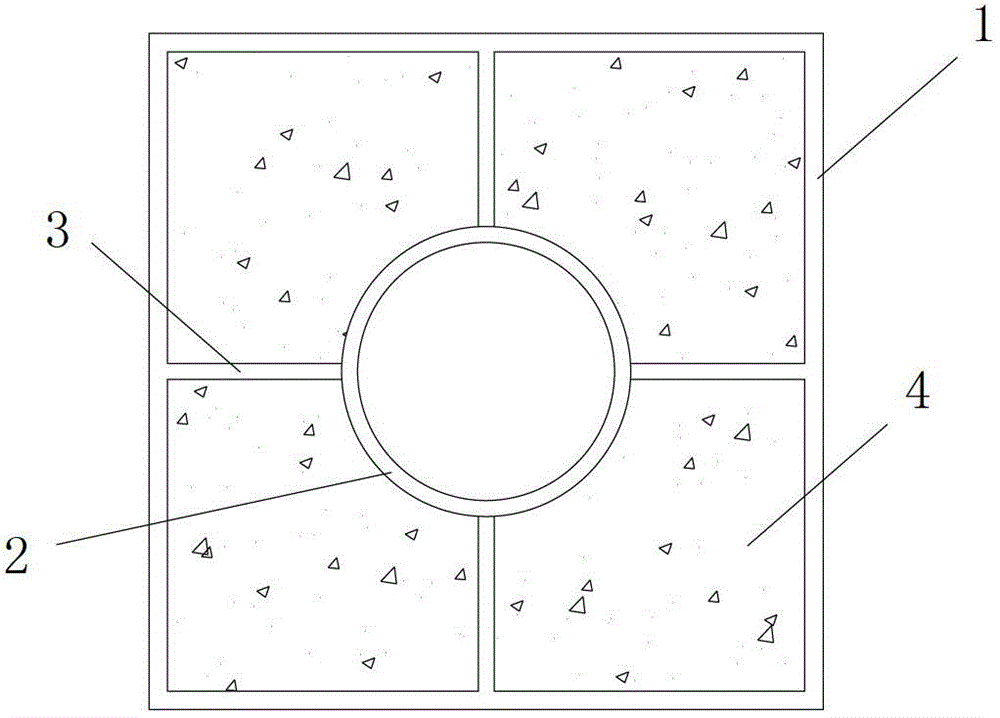

[0037] like figure 1 , figure 2 and image 3As shown, the present invention includes an outer steel pipe 1, an inner steel pipe 2 set inside the outer steel pipe 1, multiple PBL stiffeners 3 arranged between the outer steel pipe 1 and the inner steel pipe 2, and multiple PBL stiffeners 3 to be arranged. After the laying is completed, the concrete structure 4 formed by pouring the concrete filled in the cavity between the outer steel pipe 1 and the inner steel pipe 2, the inner steel pipe 2 is a circular steel pipe and it is arranged in the middle of the inner side of the outer steel pipe 1. The outer steel pipe 1 and the inner steel pipe 2 are arranged coaxially, and the laying direction of the multiple PBL stiffeners 3 is consistent with the direction of the central axis of the inner steel pipe 2 and the outer steel pipe 1, and the multiple PBL stiffeners 3 are all fastened and connected with the concrete structure 4 as a whole. The longitudinal lengths of the outer steel...

Embodiment 2

[0056] like Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the cross section of the outer steel pipe 1 is circular, A1:A2=1:0.6, and the wall thicknesses of the outer steel pipe 1 and the inner steel pipe 2 are both 25mm, A1=π·R 2 =10m 2 , where R is the outer diameter of the outer steel pipe 1.

[0057] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

Embodiment 3

[0059] like Figure 5 As shown, in this embodiment, the difference from Embodiment 2 is that the number of PBL stiffeners 3 is 6.

[0060] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com