Cold storage plate convenient to install

A technology of cold storage boards and pressing boards, which is applied to building components, heat preservation, construction, etc., and can solve problems such as low strength and poor shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

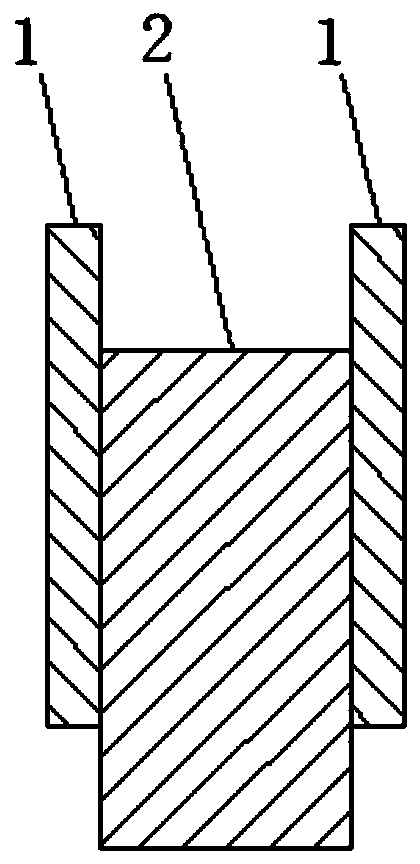

[0028] like figure 1 As shown, a cold storage panel that is easy to install includes two surface panels 1 and an insulation layer 2 arranged between the two surface panels 1. Usually, the shapes of the cold storage panels used for splicing are relatively regular, such as rectangles, and at the same time In terms of material, the insulation layer 2 is made of a material with low thermal conductivity, such as polyphenylene or polyurethane, and the surface layer 1 is made of a material with a certain strength and hardness, such as metal or wood, and the metal is made of aluminum or steel.

[0029] The two surface boards 1 are all staggered with the insulation layer 2; in the present embodiment, the two surface boards 1 are all on the same direction of the cold storage board (the direction is parallel or perpendicular to a certain side of the rectangular cold storage board) and The insulation layer 2 is staggered, and the two surface panels 1 protrude from the insulation layer 2 a...

Embodiment 2

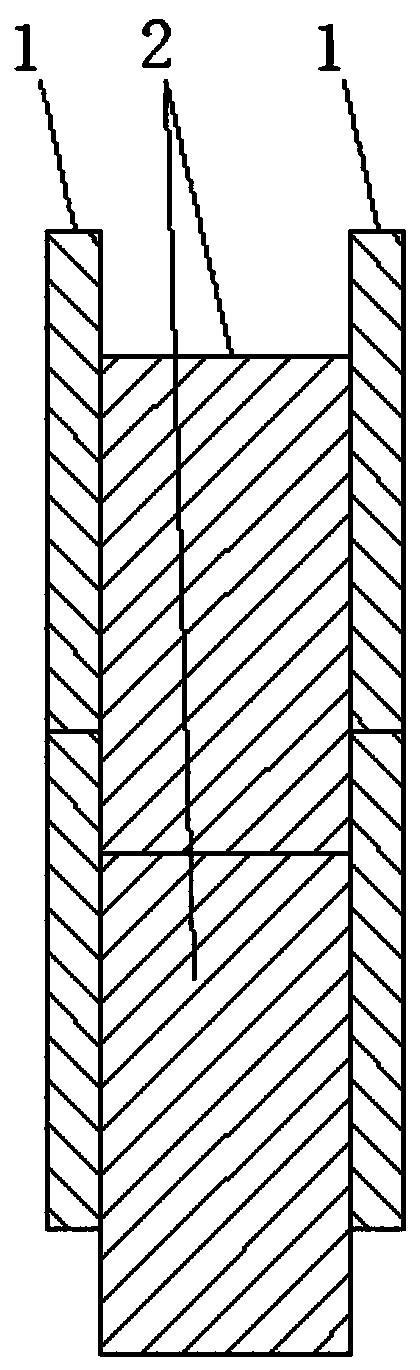

[0035] It differs from Embodiment 1 in that: the staggered lengths of the two surface panels 1 and the insulation layer 2 are not equal, such as Figure 5 As shown, in this embodiment, when splicing, the front and back sides of the cold storage board need to be distinguished, which is suitable for use in occasions where the thickness and material of the two surface boards 1 are different.

Embodiment 3

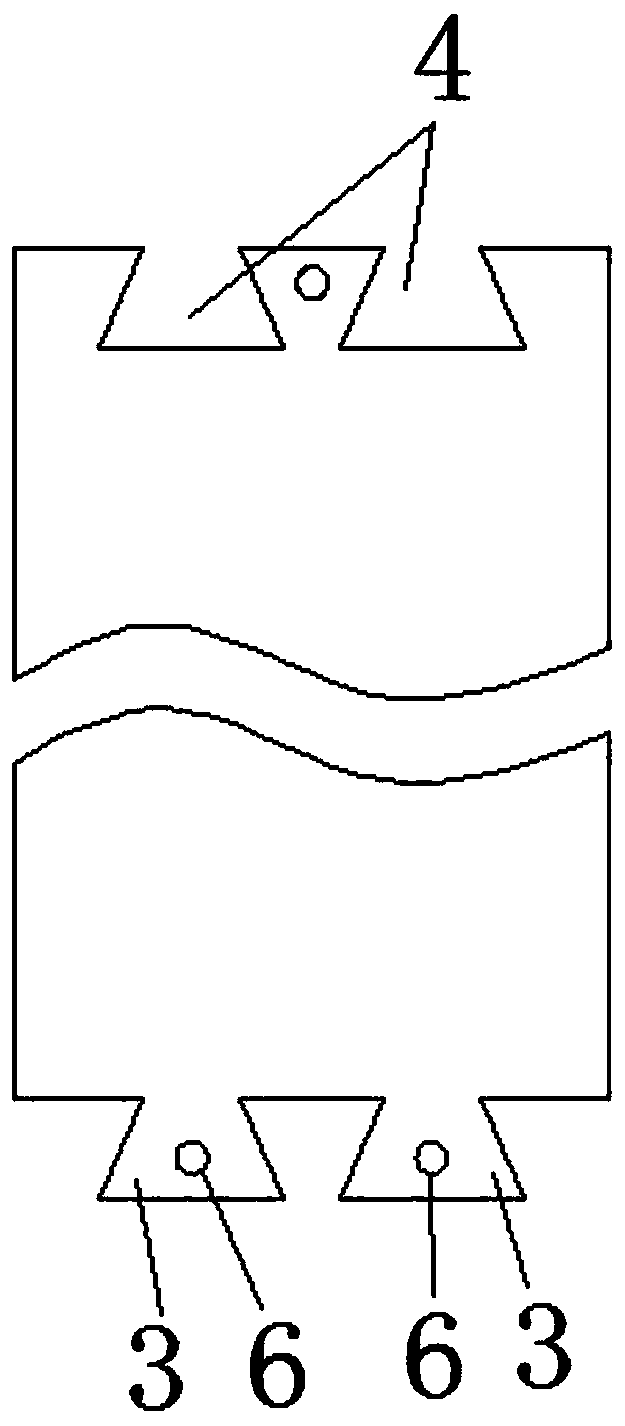

[0037] The difference between it and Embodiment 1 or Embodiment 2 is that: in this embodiment, the two surface boards 1 respectively protrude from the insulation layer 2 at the two opposite ends of the cold storage board; Image 6 as well as Figure 7 As shown, the staggered lengths of the two surface panels 1 and the insulation layer 2 are respectively shown to be equal and unequal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com