High-temperature superconducting magnet and preparation method thereof

A high-temperature superconducting and magnet technology, applied in superconducting magnets/coils, magnetic objects, coil manufacturing, etc., can solve problems such as thermal stress differences, inability to make full use of the strength of each turn of superconducting strip, and cold shrinkage of superconducting coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] refer to Figure 1 to Figure 8 A basic embodiment of the invention is shown.

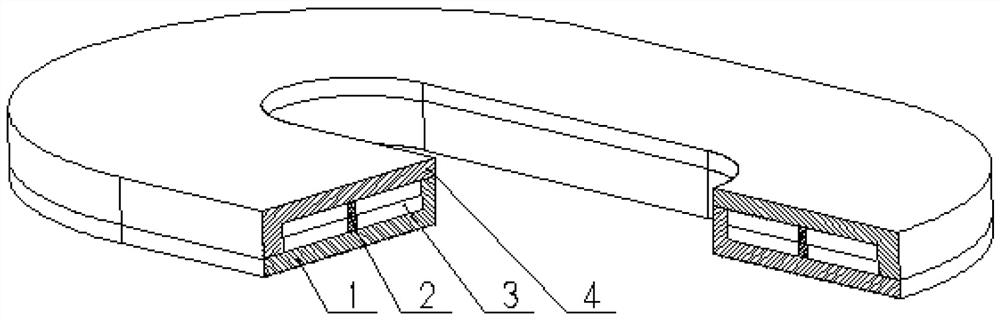

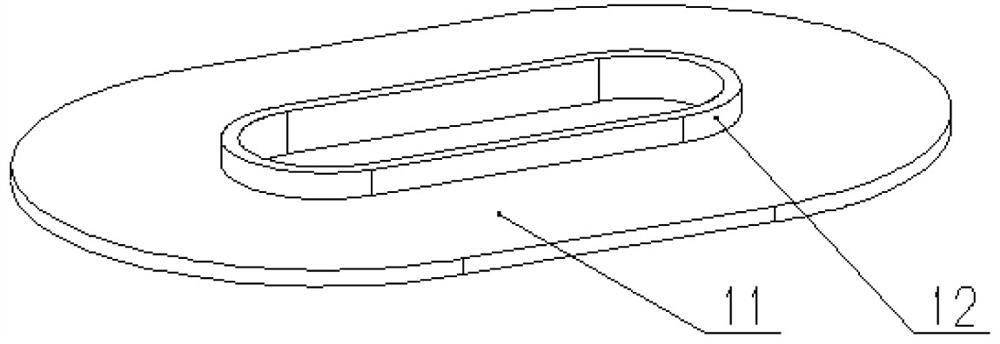

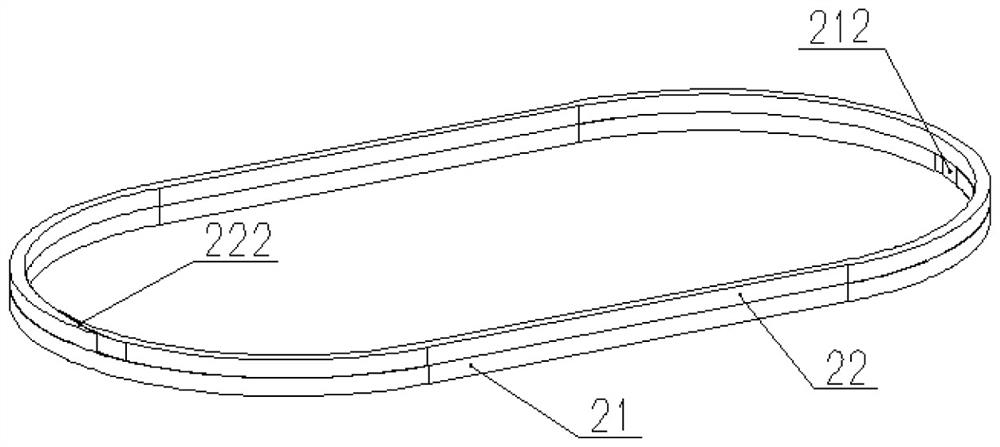

[0053] A high-temperature superconducting magnet disclosed by the present invention is composed of a superconducting coil 3, a magnet upper cover plate 4, a magnet lower bottom plate 1, and a lower spacer 21 and an upper spacer 22 arranged up and down. The superconducting coil 3 consists of Composed of two sub-superconducting coils, such as Figure 5 The first sub-superconducting coil 31 and the second sub-superconducting coil 32 shown are connected in series through a superconducting tape, wherein the first sub-superconducting coil 31 is composed of a single-cake coil 311 and a single-cake coil 312. The spacer 21 is separated, and is connected in series by the superconducting tape 313 that passes through the gap 212, and the second sub-superconducting coil 32 is composed of a single cake coil 321 and a single cake coil 322, separated by the upper spacer 22, and The superconducting strips 3...

Embodiment 2

[0055] A method for preparing a high-temperature superconducting magnet disclosed by the present invention, the superconducting coil is composed of a sub-superconducting coil, and when each sub-superconducting coil contains M+1 single-cake coils, the steps of the preparation method are as follows:

[0056] Step 1: Machining the upper cover plate 4 of the magnet, the lower bottom plate 1 of the magnet and M spacers 2 with different inner diameters, and cleaning the oil and dust on the surface of each component.

[0057] Step 2, install the M spacers 2 on the bottom plate 1 of the magnet, with drilled pin holes, and mark them.

[0058] Step 3, install and fix the magnet upper cover plate 4 on the magnet lower base plate 1 equipped with the spacer 2, equip drill pin holes, and make marks.

[0059] Step 4, remove the upper cover plate 4 of the magnet, the lower bottom plate 1 of the magnet and the M spacers 2, and clean the oil and dust on the surface of each component again.

[...

Embodiment 3

[0066] A method for preparing a high-temperature superconducting magnet disclosed by the invention comprises the following steps:

[0067] In step 1, the upper cover plate 4 of the magnet, the lower bottom plate 1 of the magnet, the lower spacer 21 and the upper spacer 22 are machined, and oil and dust on the surface of each component are cleaned.

[0068] Step 2, install the lower spacer 21 and the upper spacer 22 on the lower bottom plate 1 of the magnet, equip drill pin holes, and make marks.

[0069] Step 3, install and fix the upper cover plate 4 of the magnet on the lower bottom plate 1 of the magnet equipped with the lower spacer 21 and the upper spacer 22, and drill pin holes for marking.

[0070] Step 4, remove the upper cover plate 4 of the magnet, the lower bottom plate 1 of the magnet, the lower spacer 21, and the upper spacer 22, and clean the oil and dust on the surface of each component again.

[0071] Step 5, adjust the winding tension value and loading method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com