Sequence control system (SCS) concrete filled steel tube bridge pier with shear nails added at bottom

A technology of concrete filled steel tubes and shear nails, which is applied in the directions of bridges, bridge parts, bridge construction, etc., can solve the problems of easy bending at the upper and lower ends, poor connection performance, small hoop effect, etc., and achieves good torsional performance, Low construction cost and enhanced ferrule effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

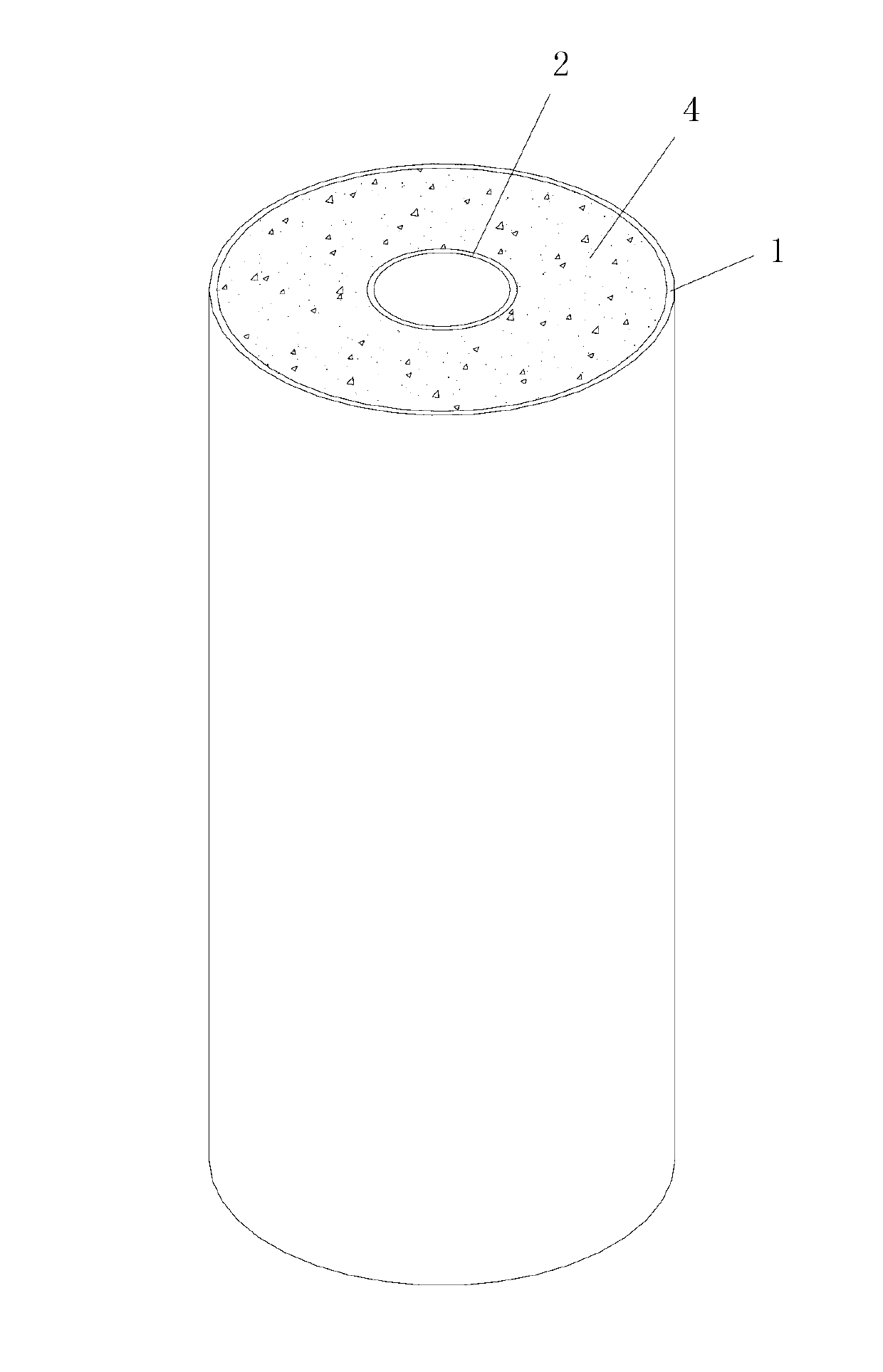

[0048] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes an outer steel pipe 1, an inner steel pipe 2 sleeved inside the outer steel pipe 1, a top shear structure arranged between the top of the outer steel pipe 1 and the top of the inner steel pipe 2, and a top shear structure arranged between the bottom of the outer steel pipe 1 and the inner steel pipe. 2. The bottom shear structure between the bottom ends is formed by pouring concrete filled in the cavity between the outer steel pipe 1 and the inner steel pipe 2 after the top shear structure and the bottom shear structure are laid out. The concrete structure 4, the inner steel pipe 2 is a circular steel pipe and it is arranged in the middle of the inner side of the outer steel pipe 1. The outer steel pipe 1 and the inner steel pipe 2 are arranged coaxially. The outer steel pipe 1 is an outer steel pipe 1, and the cross-sectional shape of the outer steel pipe 1 is circular; One and the b...

Embodiment 2

[0063] Such as Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the cross section of the outer steel pipe 1 is circular, A1:A2=1:0.6, and the wall thicknesses of the outer steel pipe 1 and the inner steel pipe 2 are both 25mm, A1=10m 2 ; The number of the plurality of top shear stud groups 1 and the plurality of bottom shear stud groups 1 is 6.

[0064] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

Embodiment 3

[0066] Such as Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that the cross-section of the outer steel pipe 1 is a regular hexagon, A1:A2=1:0.8, and the wall thicknesses of the outer steel pipe 1 and the inner steel pipe 2 are equal. 25mm, A1=10m 2 ; The number of the plurality of top shear stud groups 1 and the plurality of bottom shear stud groups 1 is 4.

[0067] In this embodiment, the structures and connections of other parts are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com