Foundation pit support pile using steel pipe pile to replace cast-in-place pile rock-socketed

A technology for foundation pit support and cast-in-place piles, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as large hidden dangers in construction safety, long construction period, shorten construction period, etc., and achieve the improvement of bedrock strength and construction speed. The effect of slow and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

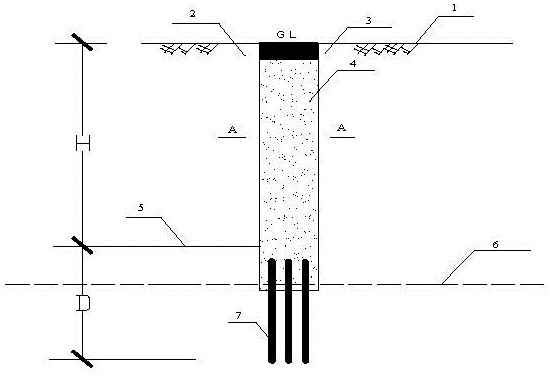

[0036] In Example 1, because the foundation pit is relatively shallow, cantilever type support piles are used after calculation, and the depth of the foundation pit is 8m.

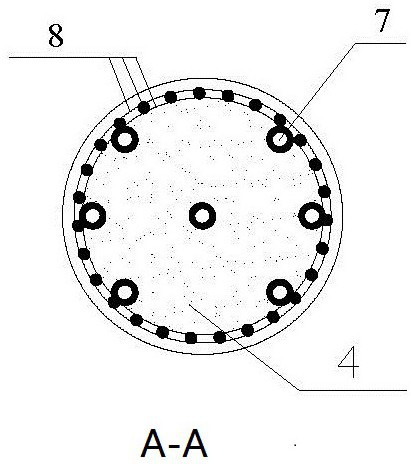

[0037] designed as figure 1 shown. According to the drawings, the supporting piles are arranged, and the holes are drilled downward from the ground with a diameter of 800mm. The drilling stops when it reaches the bedrock surface, and the bedrock surface is buried at a depth of about 9m. According to the calculation, the uniformly distributed reinforcement of the design reinforcement cage is 16 25. 4 steel pipe piles are designed, using ø89×10 seamless geological steel pipe as material, and the steel pipe pile is formed from the hole to the bottom of the hole, the hole diameter is 90mm, the steel pipe is embedded 3.0m below the bedrock surface, and extends into the support pile 1.0m, pour cement mortar into the steel pipe. After the construction of steel pipe piles is completed, the bedrock surface is c...

example 2

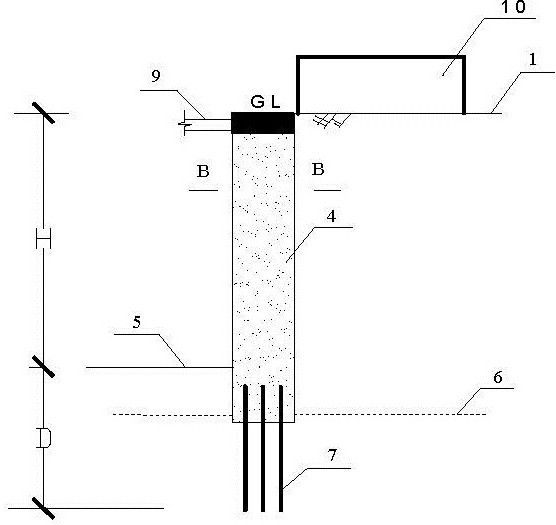

[0039] When the excavation of the foundation pit is deep and the cantilever support cannot meet the technical and safety requirements, the method of support pile plus anchorage or support is used for support. This example is an example of combined support with steel pipe support. The depth of the foundation pit is 10.0m, the geological conditions are complex, and the surrounding environment is very demanding.

[0040] Such as figure 2 , 3, 4 shown. The excavation depth of this foundation pit project is 10m. It is the sump of a smeltery wastewater "zero discharge" project. The construction period is extremely tight. The surrounding environment of the foundation pit is complex and the site is narrow. Since the foundation pit is close to the equipment factory building, large vibrations are not allowed in the surrounding area, and punching construction and blasting construction are not allowed. The support piles are designed to be supported by manual excavation piles; because t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com