Ductile connection construction and construction method for assembly type vertical component and foundation

A technology of vertical components and construction methods, which is applied in basic structural engineering, construction, etc. to achieve the effect of ensuring the performance of ductile failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

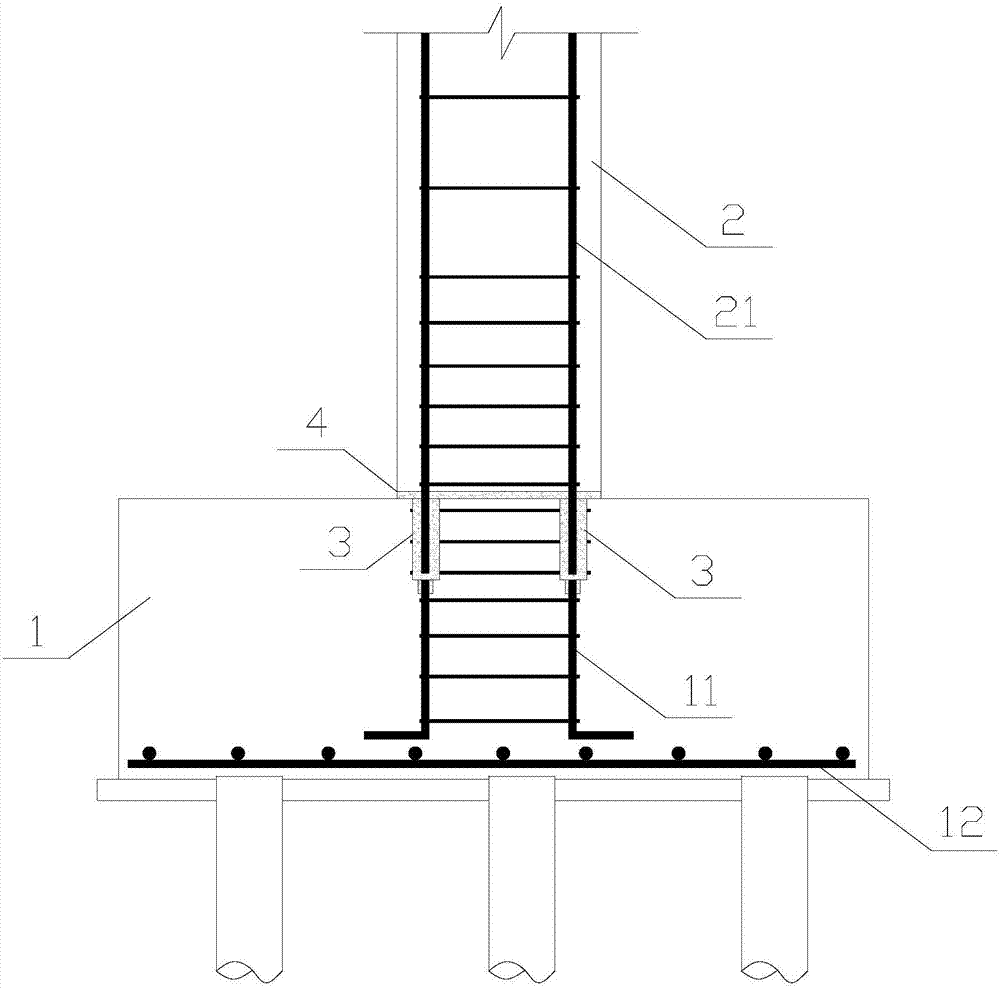

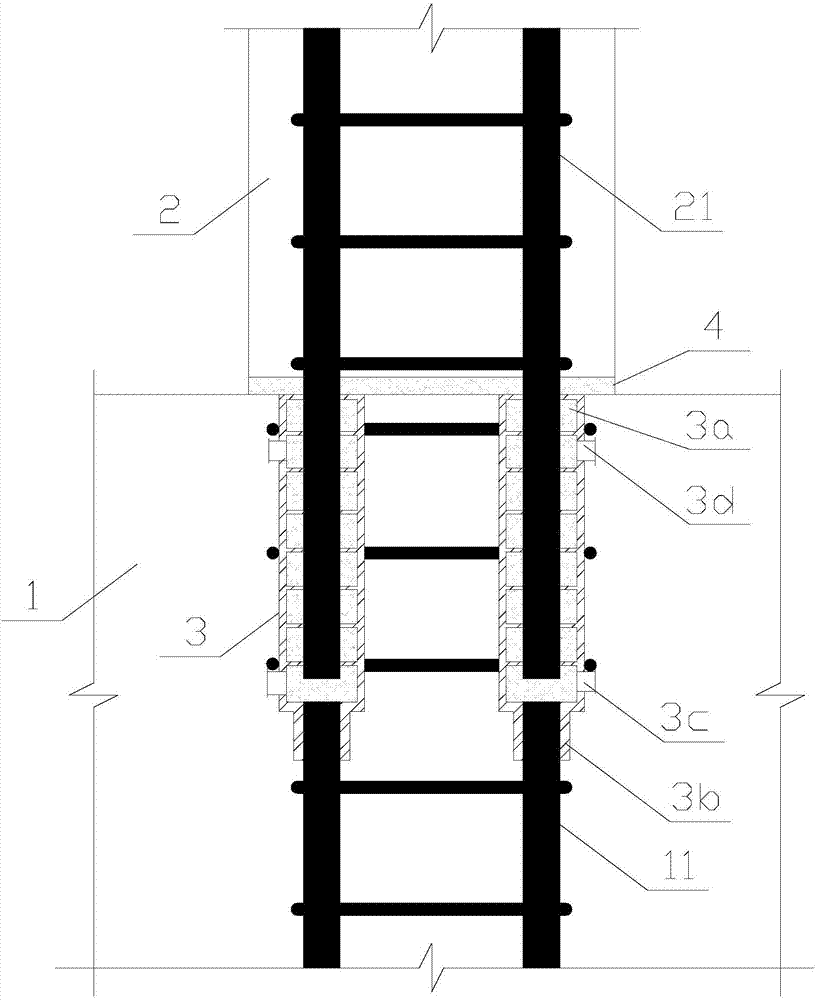

[0032] like figure 1 and figure 2As shown, the present invention discloses a ductile connection structure between an assembled vertical member and a foundation, including a cast-in-place reinforced concrete foundation 1 and a reinforced concrete prefabricated vertical member 2, and the cast-in-place reinforced concrete foundation 1 can be a shallow foundation or a It is a pile foundation, and the cast-in-place reinforced concrete foundation 1 is provided with connecting steel bars 11 for connecting the reinforced concrete prefabricated vertical members 2 , and the number of connecting steel bars 11 corresponds to the longitudinal bars 21 of the reinforced concrete prefabricated vertical members 2 .

[0033] The inventive concept of the present invention is: the cast-in-place reinforced concrete foundation 1 is pre-embedded with grouting sleeves 3 corresponding to the number of longitudinal bars 21, and the grouting opening 3c and the grouting opening 3d of the grouting sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com