Heat-contraction and cold-expansion pavement crack repairing agent and production process thereof

A technology for pavement cracks and production technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of poor water sealing effect, great manpower consumption, material strength, etc., and achieve simple manufacturing process, long service life, and sticky knot firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 pavement crack repairing agent (winter use type) of the present invention

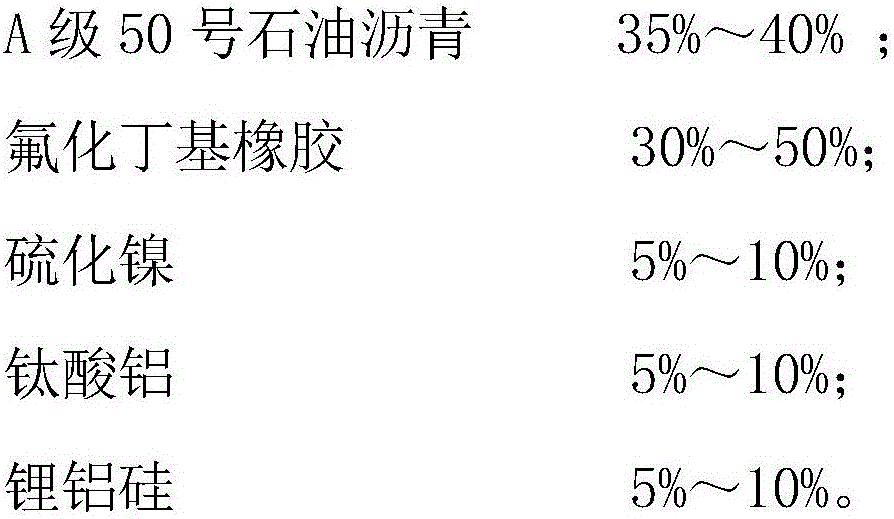

[0027] composition:

[0028]

[0029] The production process includes the following steps:

[0030] (1) Grinding fluorinated butyl rubber into powder with a fineness greater than 50 mesh;

[0031] (2) Grinding nickel sulfide, aluminum titanate and lithium aluminum silicon into powder with a fineness greater than 100 mesh;

[0032] (3) Add Grade A No. 50 petroleum asphalt into the heating kettle and heat it to 175 degrees;

[0033] (4) Add fluorinated butyl rubber, stir vigorously for not less than 10 minutes, and keep the temperature at 160°C to 175°C during stirring;

[0034] (5) drop the temperature to 80°C;

[0035] (6) Add nickel sulfide, aluminum titanate and lithium aluminum silicon, stir vigorously for not less than 20 minutes, and keep the temperature at 75°C to 80°C during stirring;

[0036] (7) Take it out from the heating kettle, cool to normal ...

Embodiment 2

[0037] The preparation of embodiment 2 pavement crack repairing agent (summer type) of the present invention

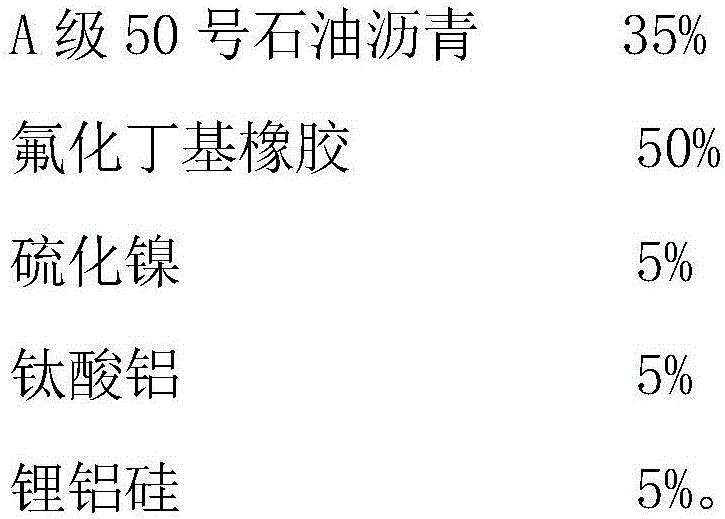

[0038] composition:

[0039]

[0040] The production process includes the following steps:

[0041] (1) Grinding fluorinated butyl rubber into powder with a fineness greater than 50 mesh;

[0042] (2) Grinding nickel sulfide, aluminum titanate and lithium aluminum silicon into powder with a fineness greater than 100 mesh;

[0043] (3) Add Grade A No. 50 petroleum asphalt into the heating kettle and heat it to 175 degrees;

[0044] (4) Add fluorinated butyl rubber, stir vigorously for not less than 10 minutes, and keep the temperature at 160°C to 175°C during stirring;

[0045] (5) drop the temperature to 80°C;

[0046] (6) Add nickel sulfide, aluminum titanate and lithium aluminum silicon, stir vigorously for not less than 20 minutes, and keep the temperature at 75°C to 80°C during stirring;

[0047] (7) Take it out from the heating kettle, cool to normal temp...

Embodiment 3

[0048] Embodiment 3 Preparation of pavement crack repairing agent (spring and autumn type) according to the present invention

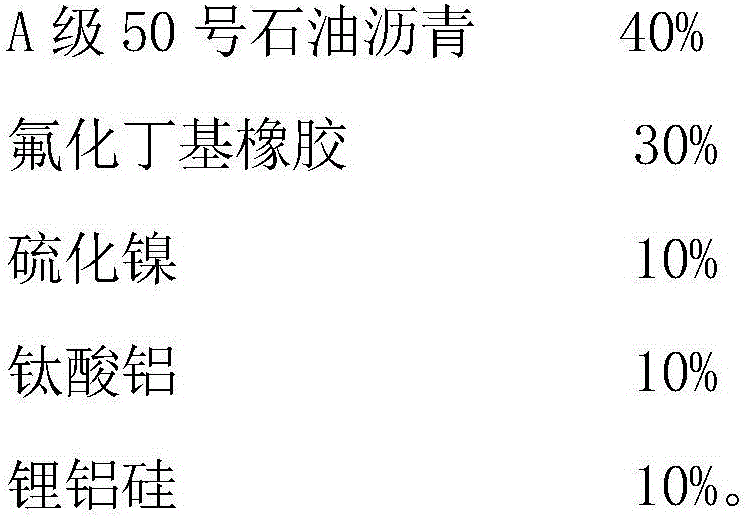

[0049] composition:

[0050]

[0051]

[0052] The production process includes the following steps:

[0053] (1) Grinding fluorinated butyl rubber into powder with a fineness greater than 50 mesh;

[0054] (2) Grinding nickel sulfide, aluminum titanate and lithium aluminum silicon into powder with a fineness greater than 100 mesh;

[0055] (3) Add Grade A No. 50 petroleum asphalt into the heating kettle and heat it to 175 degrees;

[0056] (4) Add fluorinated butyl rubber, stir vigorously for not less than 10 minutes, and keep the temperature at 160°C to 175°C during stirring;

[0057] (5) drop the temperature to 80°C;

[0058] (6) Add nickel sulfide, aluminum titanate and lithium aluminum silicon, stir vigorously for not less than 20 minutes, and keep the temperature at 75°C to 80°C during stirring;

[0059] (7) Take it out from the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com