FRP rib seawater sea sand-ultra high ductile cementitious composites (UHDCC) composite beam and construction method thereof

A composite beam and seawater technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of poor ductility and crack resistance, and achieve the effects of improving bending resistance, increasing strength, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

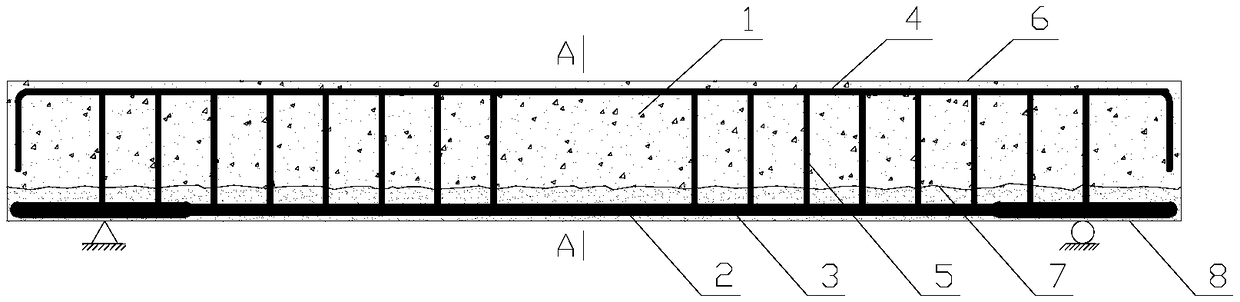

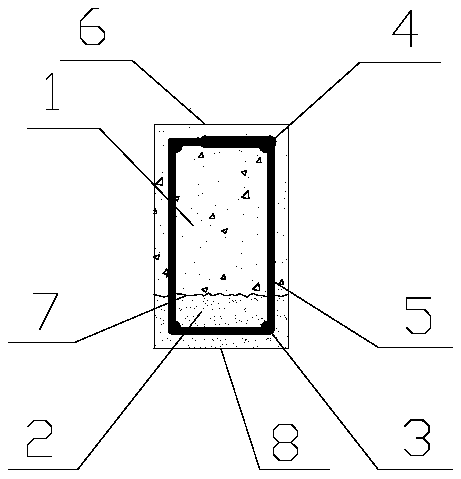

[0035] A FRP reinforced seawater sea sand-UHDCC composite beam, in which UHDCC (Ultra-high DuctileCementitious Composites, ultra-high ductility cement-based composites) overcomes the softening performance of traditional cement-based materials under tensile loads, and behaves similar to metal materials The pseudo-hardening characteristics of the traditional cement-based materials can achieve a breakthrough from the single-crack macro-crack development mode to the multiple micro-crack steady-state cracking mode. It has significant nonlinear deformation, excellent crack resistance, ductil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com