Quickly-installed steel-concrete combined beam bridge and construction method thereof

A technology of concrete and composite beams, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve problems such as the inability to achieve rapid construction, and achieve the effects of stable and controllable component connection quality, easy quality assurance, and reduced shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments of the present invention are described in detail below with reference to the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. Although the invention has been described in conjunction with its preferred specific embodiments, these embodiments are intended to illustrate, and not to limit, the scope of the invention.

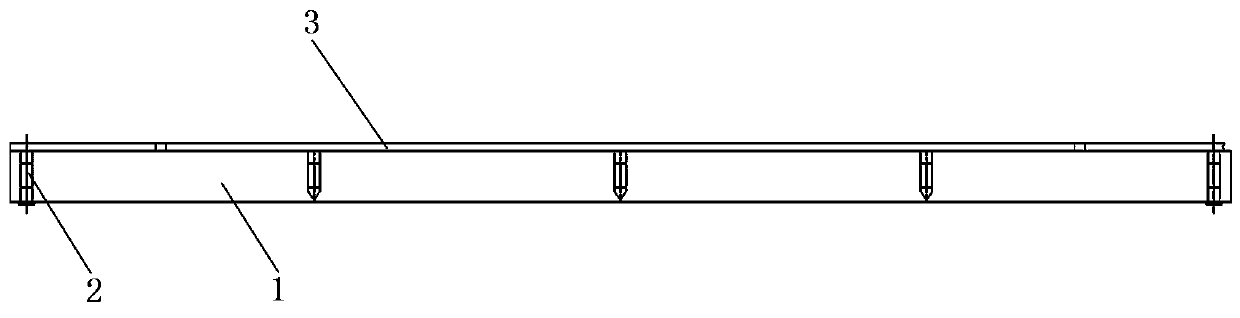

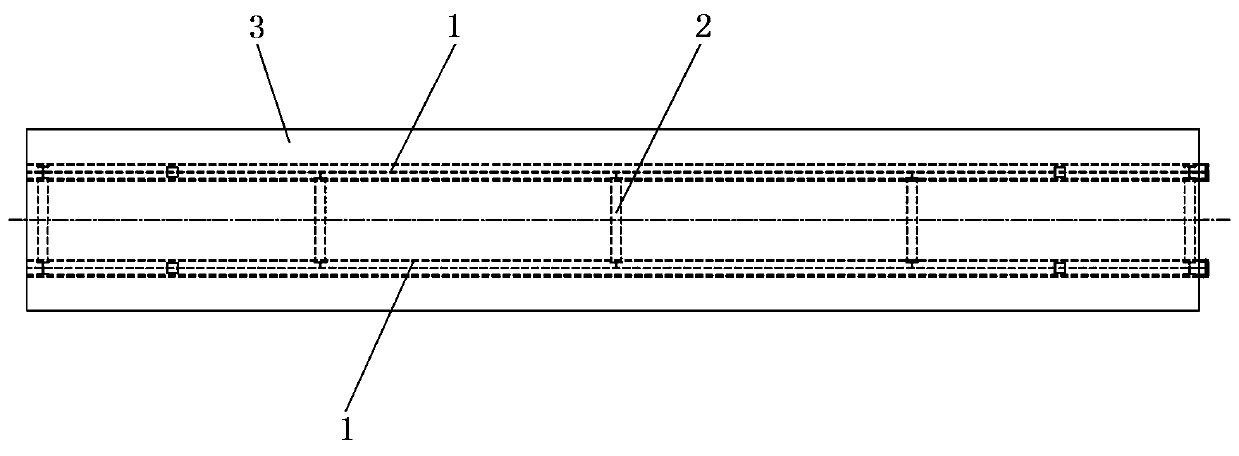

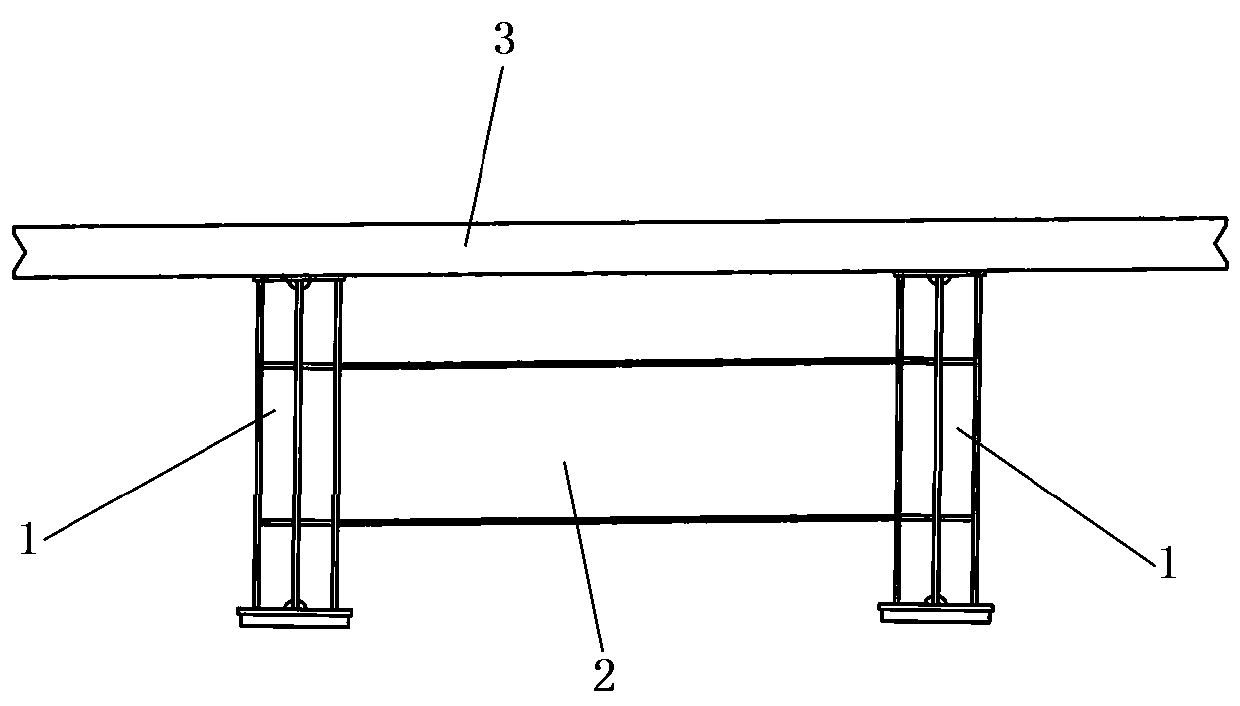

[0048] A steel-concrete composite girder bridge for rapid installation includes several steel-concrete composite girder. see Figure 1 to Figure 3 , the steel-concrete composite beam includes two parallel steel beams 1 , several cross beams 2 connecting the two steel beams 1 , and a concrete bridge deck 3 cast on the top plate of the two steel beams 1 . Several horizontal pieces of the steel-concrete composite beams are connected to form a span beam body, and a plurality of the vertical span beam bodies are connected to form a bridge.

[0049] The difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com