Corrugated steel web few-main-beam structure

A corrugated steel web and beam structure technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of large amount of formwork engineering and on-site wet work, the impact of existing urban traffic, and the relatively large impact of the surrounding environment. Achieve the effect of reducing the amount of concrete, shortening the construction period and speeding up the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

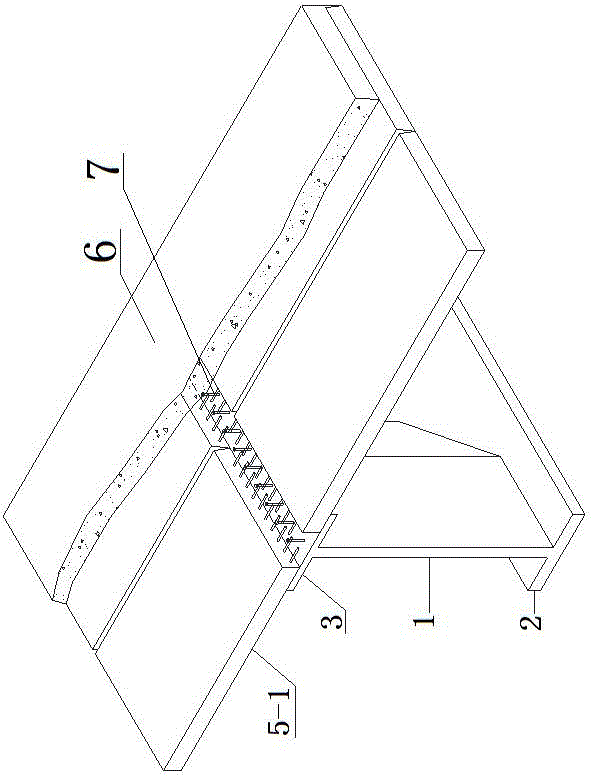

[0036] The prefabricated segmental bridge deck structure of corrugated steel web less main girder bridge, including multiple corrugated steel web girders, the prefabricated segmental bridge deck 5-1 set on the corrugated steel web, the prefabricated segmental bridge deck 5-1 The upper pavement is provided with a bridge deck pavement layer 6;

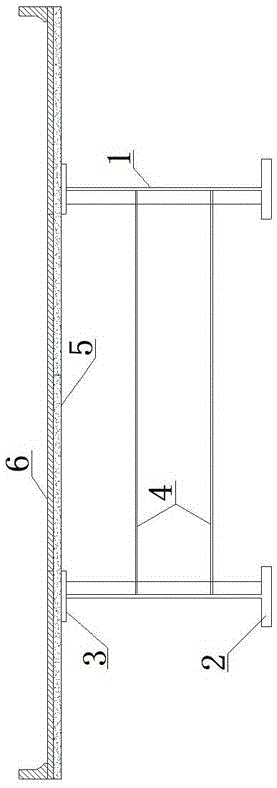

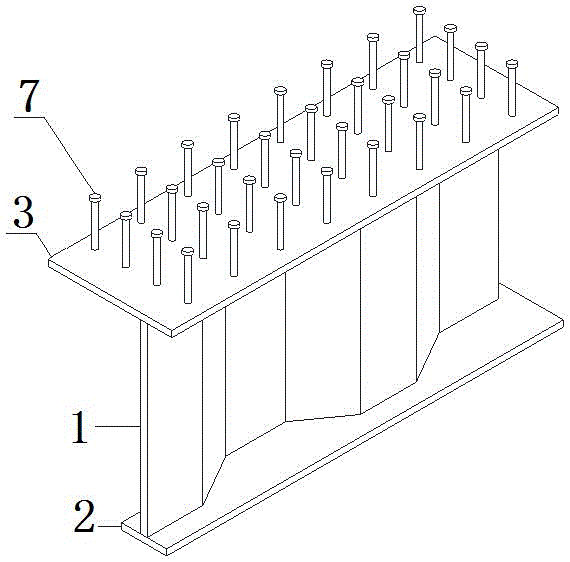

[0037] The corrugated steel web girder comprises a corrugated steel web 1, a lower flange steel plate 2 arranged below the corrugated steel web 1 and an upper flange steel plate 3 arranged above the corrugated steel web 1; the corrugated The steel web 1 is welded to the upper flange steel plate 3 and the lower flange steel plate 2 respectively; the lower flange steel plate 2 at the support is a thickened steel plate;

[0038] The upper flange steel plate 3 is provided with a plurality of stud groups 7, and the studs forming the stud group 7 are arranged intermittently; the upper flange steel plate 3 and the plurality of stud groups 7 are...

Embodiment 2

[0040] The overall prefabricated bridge deck structure of the corrugated steel web less main girder bridge includes multiple corrugated steel web girders, the prefabricated integral concrete bridge deck 5-2 set on the corrugated steel web, and the prefabricated integral concrete bridge deck 5-2 A bridge deck pavement layer 6 is laid;

[0041] The corrugated steel web girder comprises a corrugated steel web 1, a lower flange steel plate 2 arranged below the corrugated steel web 1 and an upper flange steel plate 3 arranged above the corrugated steel web 1; the corrugated The steel web 1 is welded to the upper flange steel plate 3 and the lower flange steel plate 2 respectively; the lower flange steel plate 2 at the support is a thickened steel plate;

[0042] The upper flange steel plate 3 is provided with a plurality of stud groups 7, and the studs forming the stud group 7 are arranged intermittently; the upper flange steel plate 3 and the plurality of stud groups 7 are welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com