Rib-free beam mold box sandwiched reinforced concrete floor system

A reinforced concrete and concrete technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of difficulty in forming the whole floor at one time, unreasonable one-way force on the floor, and insignificant effect, so as to reduce the amount of concrete and reduce the deformation. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

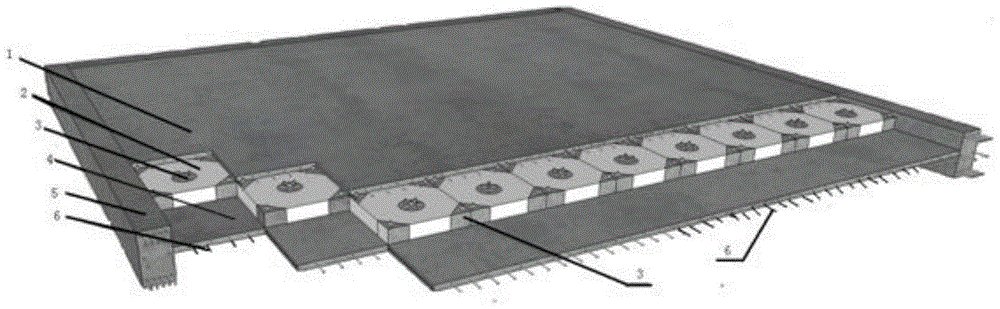

[0023] Such as figure 1 As shown, the ribless beam formwork box sandwich reinforced concrete floor slab of the present invention includes a double-layer reinforcement cage and a lightweight insulation board formwork composed of upper and lower layers of steel mesh; it can be divided into upper reinforced concrete slabs as a whole 1. Lightweight thermal insulation board formwork 2, lower reinforced concrete slab 4 and concrete columns 3 connecting the upper and lower panels formed by pouring concrete in the holes of lightweight thermal insulation board formwork 2.

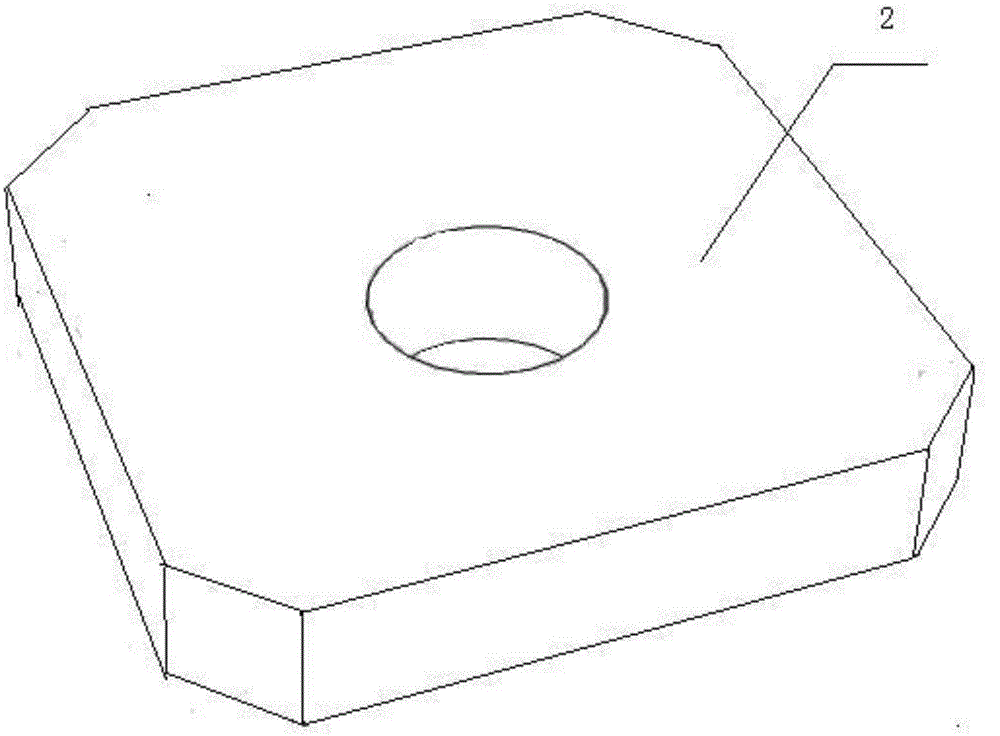

[0024] The lightweight thermal insulation board mold box 2 is formed by cutting four right angles from a square mold box. The lightweight thermal insulation board mold box 2 is centrally symmetrical. There is a hole at the central point of the lightweight thermal insulation board mold box 2 .

[0025] In particular, it should be noted that the two opposite sides or four sides of the ribless beam formwork sandwich re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com