Cast-in-situ X-shaped concrete pile construction method

A technology of reinforced concrete and construction methods, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing project cost, increasing construction difficulty, cost, etc., achieving high bearing capacity, saving concrete consumption, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

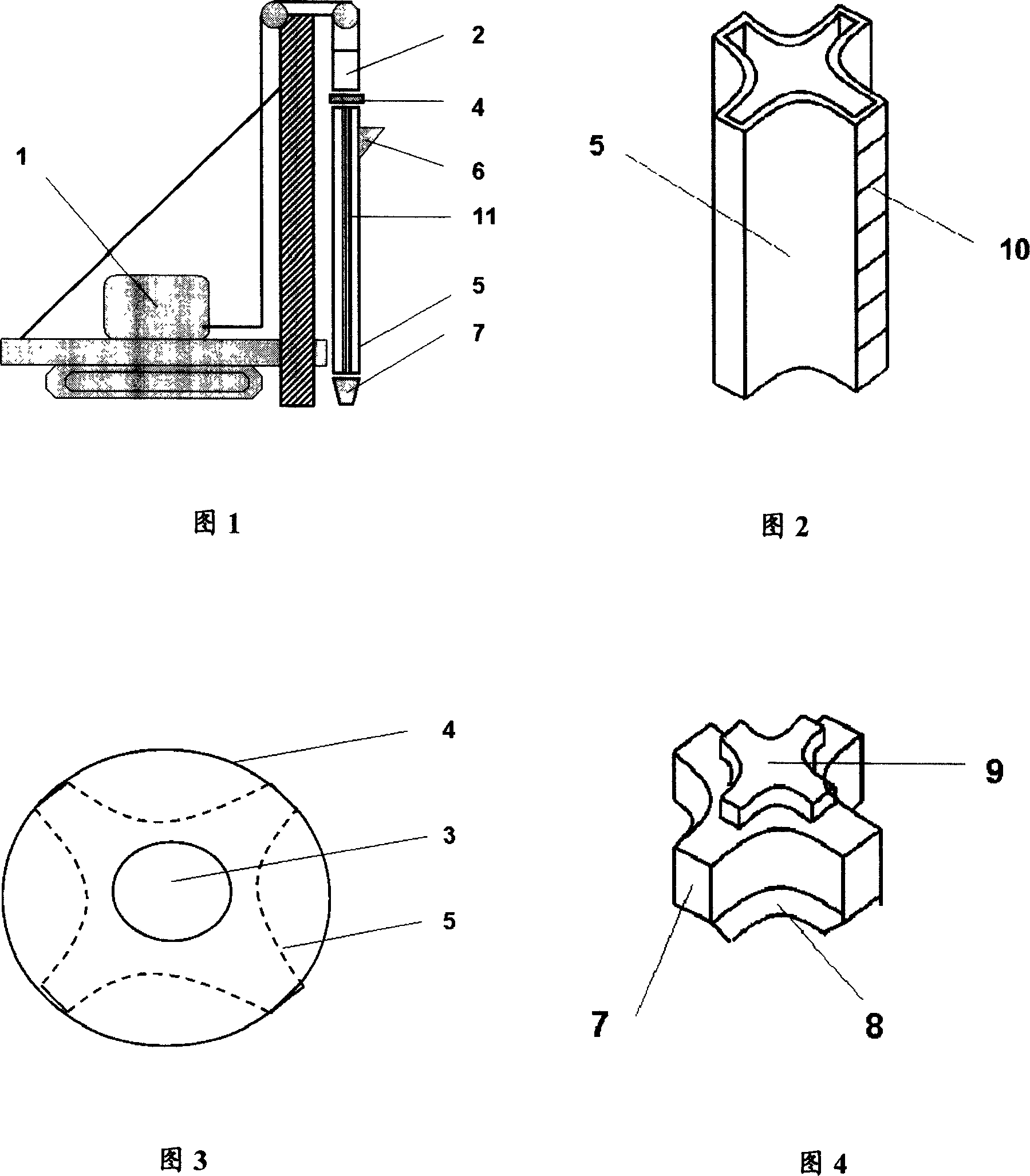

[0019] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, a vibrating head 2 is arranged on the upper part of the vibrating pile driver 1, and the lower part of the vibrating head 2 is riveted with the cover plate 4, and the cover plate 4 is made of steel, and The upper ends of the X-shaped steel sleeves 5 are welded; the middle of the cover plate 4 is provided with a round hole 3, and the middle of the X-shaped steel sleeves 5 is a cavity, which has considerable hardness and strength; the prefabricated X-shaped reinforced concrete pile shoes 7 The lower part has an integrally cast cutting edge 8, and the upper part has an integrally cast X-shaped connector 9; the X-shaped steel casing 5 and the prefabricated X-shaped reinforced concrete spud shoe 7 connected to the lower part constitute a special mold for sinking piles. Device; the outer side of the upper part of the X-shaped steel casing 5 is provided with a concrete feed port 6, and the outer side of the X-shaped steel casing 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com