Construction technology of basement cast-in-situ hollow floor slab steel mesh box

A technology of hollow floor and construction technology, which is applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of slow construction formwork progress, increased construction cost, unfavorable equipment installation, etc., so as to save concrete consumption, reduce project cost, reduce The effect of structural self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

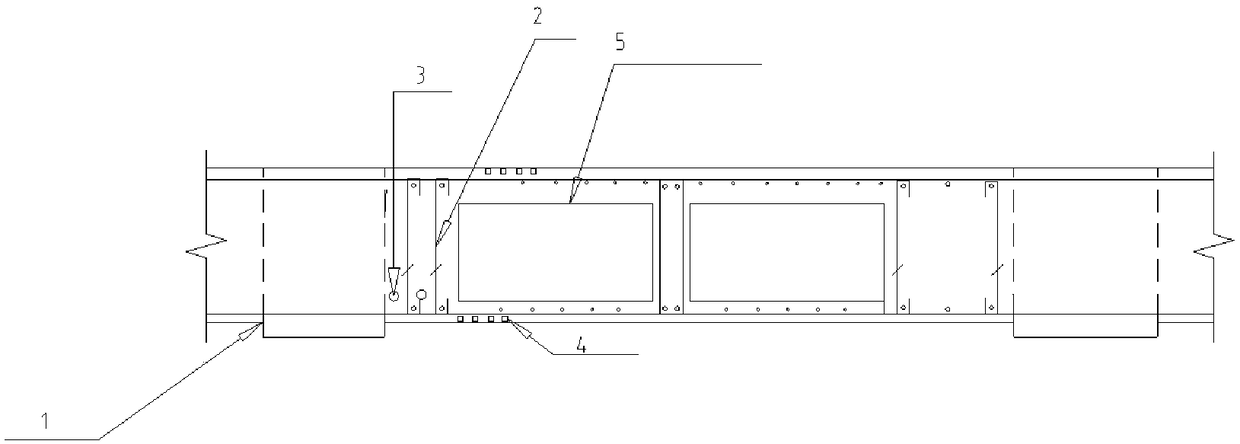

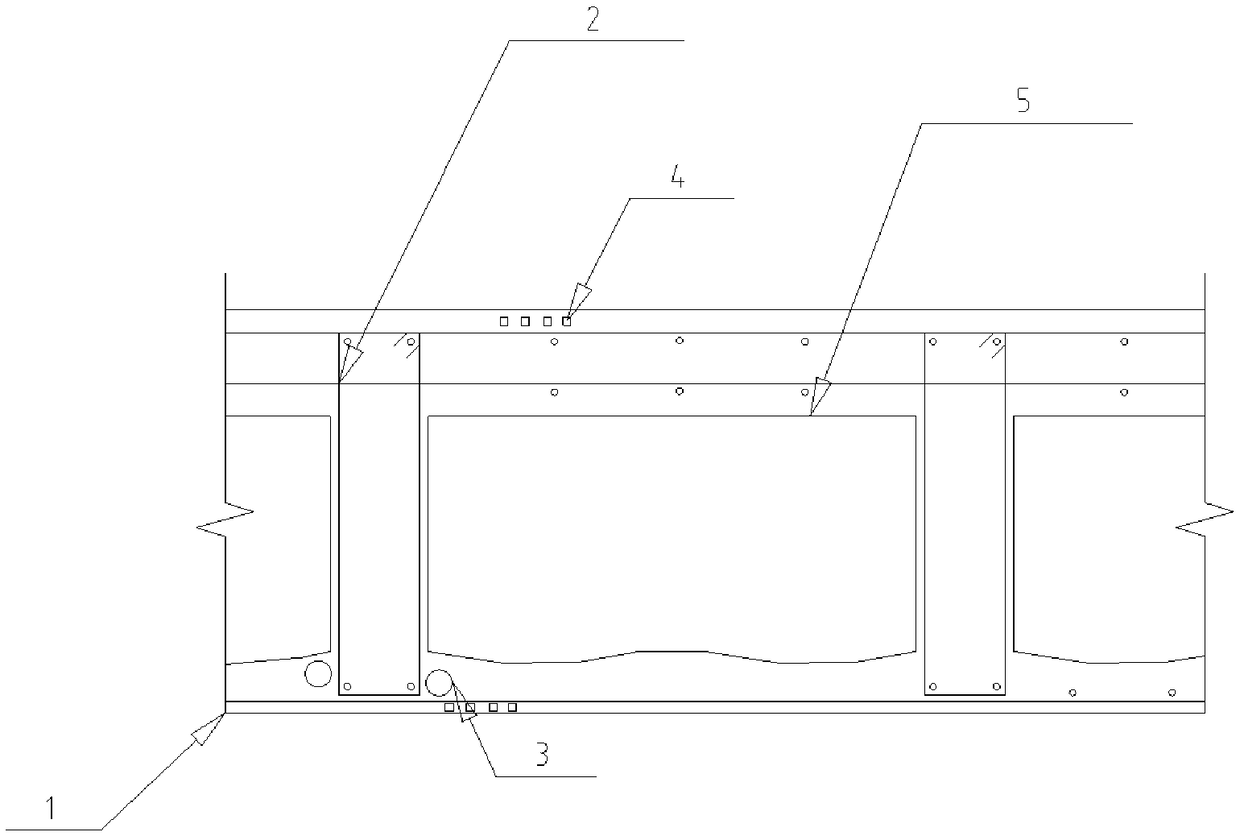

[0032] Such as Figure 1-2 As shown, the construction process of the basement cast-in-place hollow floor steel mesh box is implemented according to the following steps:

[0033] Step 1, use the ink cartridge to eject the placement position line 1 of the steel bar and the box mold;

[0034] Step 2, bind the bottom iron of the floor slab and the side rib beam 2 of the box form according to the pop-up position line;

[0035] Step 3, laying the embedded pipeline 3 along the rib beam as far as possible in the rib beam section;

[0036] Step 4, install the lower cushion block 4 of the steel cage mold;

[0037] Step 5, utilizing the welded open reinforcement cage (the inside four sides and the bottom surface are closed with multi-layer boards) or other box-type tools to lift the steel cage mold 5;

[0038] Step 6, after installing the steel cage formwork, bind the iron on the floor;

[0039] Step 7, in order to avoid the deformation or damage of the box formwork caused by trampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com