Cable stayed bridge with semi-floating truss type bridge towers

A truss-type, cable-stayed bridge technology, applied in the field of bridge structure construction, can solve the problems affecting the driving smoothness and comfort of the bridge deck, difficult to control creep deformation, etc., so as to reduce the maintenance and repair workload and reduce the thickness of the bearing platform. And the effect of concrete volume and reducing temperature span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

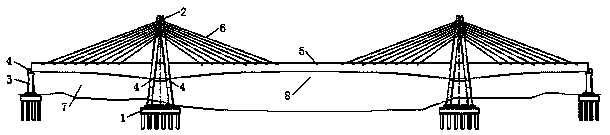

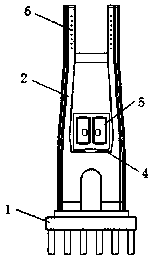

[0025] Such as Figure 1~2 As shown, a cable-stayed bridge with semi-floating truss-type pylons includes side piers 3 on both sides and a bridge tower 2 in the middle, and supports 4 are provided at the middle of the bridge tower 2 and the upper ends of the side piers 3, so that A main girder 5 that directly bears the load of the bridge deck is arranged on the support 4 , multiple pairs of stay cables 6 are arranged between the bridge tower 2 and the main girder 5 , and the bridge tower 2 is separated from the main girder 5 .

[0026] The bridge tower 2 is a truss type bridge tower with integrated tower pier and separated tower beams.

[0027] The pylons 2 are A-shaped in the longitudinal direction, and the pylons 2 are H-shaped in the transverse direction.

[0028] The support 4 is a longitudinal movable support and a two-way movable support, and two rows of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com